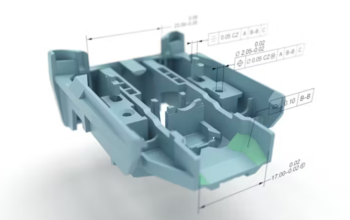

Less effort, lower costs: Virtual Clamping

Virtual Clamping simulates the clamping of components in the GOM software and enables the clamped state to be calculated using the data from the real component in the unclamped state. This step is fully integrated into the GOM workflow, you don’t have to leave the proven software interface.

Advantages of virtual clamping

With virtual clamping you reduce the costs for measurement recordings. The multiple design and production of measurement recordings for individual process steps is no longer necessary. The entire surface is freely accessible for the measurement. You get test results with significantly less operator influence and higher repeatability.

Easy measurement of hot-formed components

Thanks to a universal structure and the 3D measuring machine ATOS ScanBox, individual measuring recordings are superfluous and production processes are accelerated.

New features of Virtual Clamping

More possibilities

The Virtual Clamping module in the GOM software expands the range of applications for virtual clamping to include add-on parts such as vehicle doors or flaps. In addition, users can display both the stress-free state and the stressed state on one report page without having to measure twice.

Pneumatic measurement recording

To compensate for the weight force, GOM has developed a universal pneumatic holder that allows sheet metal components in particular to be picked up without tension and thus prepare them for the later virtual clamping process step.

Quantum Leap

With Virtual Clamping, GOM is developing a new technology for the virtual clamping of plastic and sheet metal components.