- According to the Global ABB Automotive Manufacturing Outlook Survey, supply chain issues are shifting away from the just-in-time strategy and towards higher stock-holding.

- The emphasis on operational and energy efficiency gains through automation is becoming more intense due to rising expenses and a desire to operate more sustainably.

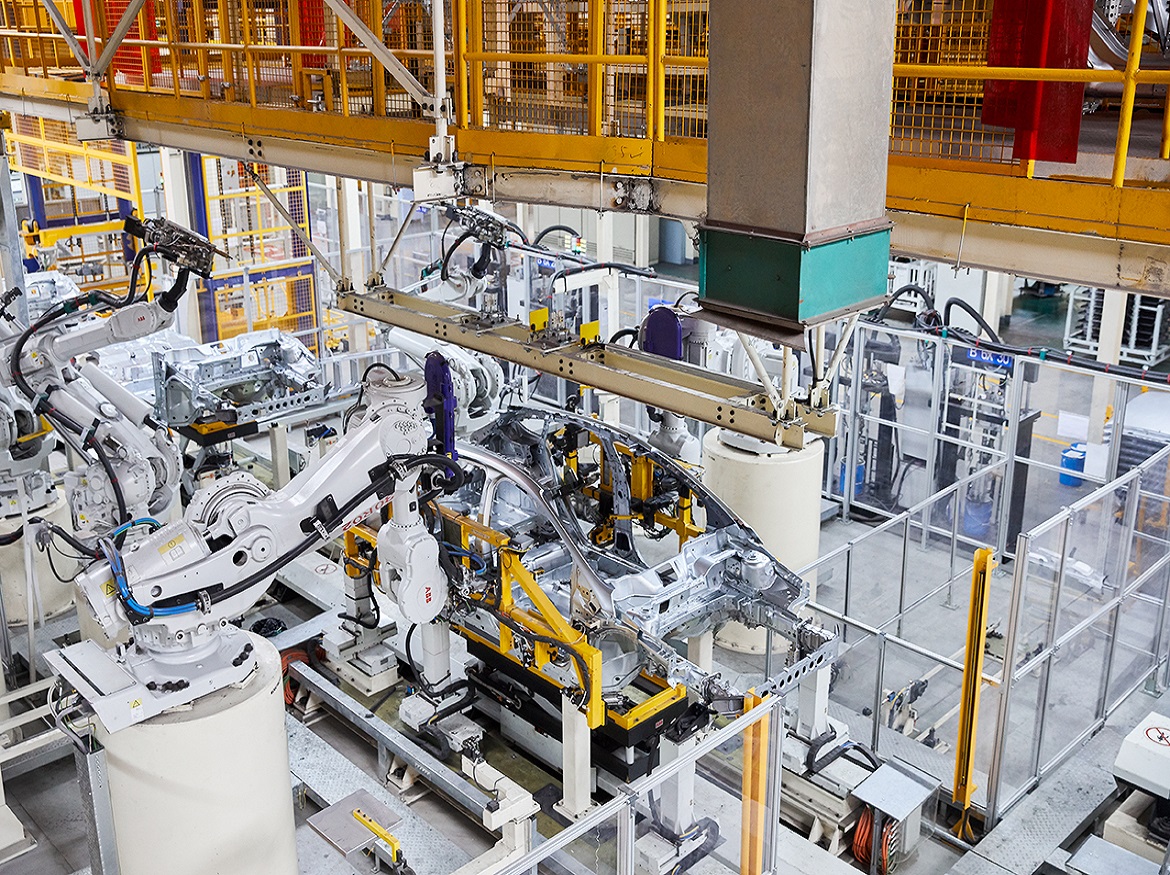

- Autonomous Mobile Robots (AMR)-based solutions from ABB handle these difficult problems.

According to a recent poll commissioned by ABB Robotics, supply chain disruption, and increased material costs are forcing the global automobile industry to reconsider lean manufacturing methods. Manufacturers retain more stock as they switch from “just-in-time” to “just in case” tactics to guard against unforeseen disruptions.

A diverse group of international industry professionals from vehicle manufacturers, suppliers, and engineering participated in the study, which was created in collaboration with the top industry periodical Automotive Manufacturing Solutions. When asked to name the top three obstacles facing the automotive industry, 62% of respondents named continued supply chain issues, followed by 41% by the effects of rising material and component prices, and 31% by rising labor costs and shortages. In order to reduce their exposure to disruptions elsewhere in the supply chain, manufacturers were turning to expanded stock holding and bulk material purchases, while also collaborating with a larger network of suppliers to ensure adequate part availability.

The poll showed that the industry’s top issue had already shifted from energy costs (59%) to the rising cost of raw materials (62%). While a similar percentage of respondents (17%) believed that tighter cost management was essential for the industry’s response, energy efficiency remains critical. After their 2022 debut, cutting-edge products like ABB PixelPaint will help manufacturers better control costs while conducting more sustainably after they help minimize waste and boost efficiency in vehicle painting applications.

Nearly 600 global industry experts from auto suppliers, manufacturers, and management at all levels, as well as engineers and other important professionals, participated in the ABB study.

Credits: Global ABB

Click on the following link, Metrologically Speaking to read more such news about the Metrology Industry.