Mapvision Editor Suite gives greater control and flexibility over in-line metrology. Find out more about why this is the measurement software of the future.

The automotive sector now relies heavily on in-line metrology equipment. They make sure that numerous parts, including battery trays, subframes, and body-in-white parts, are accurate and of high quality. These tools enable producers to monitor production in real-time and make necessary adjustments before minor difficulties turn into significant ones.

The software that comes with these gadgets, however, may limit their usefulness. The software is frequently rigid, making it challenging to implement new measuring features or respond to engineering change requests (ECRs). Additionally, users could be forced to rely too heavily on device manufacturers’ customer support teams, which makes it difficult for them to be independent and change their measuring reference as necessary.

Thankfully, Mapvision Editor Suite takes care of these concerns and gives automotive professionals more freedom and control over their in-line metrology equipment. Some of the factors that make this software the software of the future are discussed in this article.

In a nutshell, Editor Suite enables:

- responding to change requests without a delay

- easy usage and adding new feature measurements

- adjusting measurement routines independently

- retrospective measurements and virtual sorting

With the Editor Suite, you can skip the endless support loop and take control of your production line’s quality inspection. Keep reading to learn more!

Respond to Change Requests Immediately

In a busy manufacturing line, deploying engineering change requests (ECRs) takes a lot of time and money.

Users of Editor Suite can programme new measurement capabilities and update the inspection programme in minutes as opposed to hours. This makes it simple to adjust to shifting requirements, ECRs, and to perform measurements in the past. By using Editor Suite, you may use Mapvision Q-series to measure process performance right after following line edits, minimising line downtime.

Easy to use and add new feature measurements

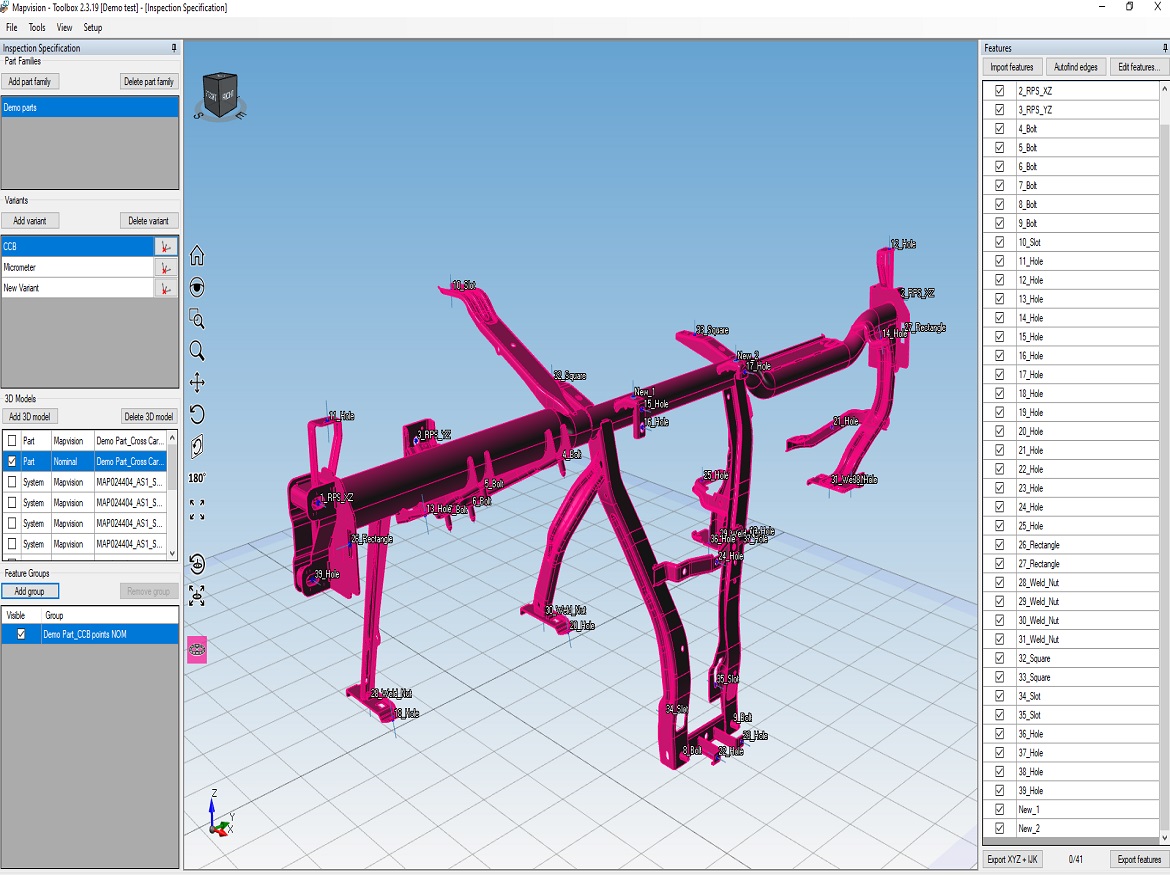

Editor Suite’s simplicity of use—everything is constructed graphically on top of the 3D CAD model—is one of its main advantages. The software will automatically build the measurement procedure when users have selected the feature they wish to measure from the CAD model. This makes it simple to add new features, even for intricately calculated complex geometries.

A factory, for instance, has to gauge the flatness of a stamped item with a complicated curve. The old method could need a lot of programming work and trial and error to get the desired outcome. The user only needs to choose the feature from the 3D CAD model in Mapvision Editor Suite, and the programme will automatically build the measurement procedure while taking into account the intricate geometry and any necessary computations.

Users of Mapvision Editor Suite can perform upgrades without substantial technical or software knowledge thanks to the package’s detailed instructions. Regardless of their level of familiarity with in-line metrology devices, this makes it available to a wide spectrum of automotive specialists.

Measurement fine-tuning

The software’s capacity to improve measurement accuracy and precision is another advantage. Users can fine-tune their measurement parameters to get the precise outcomes they need, guaranteeing that their components adhere to the high quality requirements demanded by the OEMs and automotive industry.

By modifying your measurement reference as necessary with Mapvision Editor Suite, you can make sure that your devices are consistently producing accurate readings that are within the permitted variation range. A simple user interface allows you to adjust your measurement reference, and you can resolve the issue on your own without Mapvision’s assistance. Systems may be quickly updated offline without affecting production, and they can be quickly deployed during a shift change.

Retrospective measurement and virtual sorting

The Mapvision Editor Suite’s retrospective inspection features give producers more control and flexibility over the quality control procedures. The data gathered by the gadget may always be remembered for subsequent inspections because it serves as a visual digital twin and reflects the complete part. The programme can lower the likelihood of quality problems and enhance overall product quality while also lowering costs related to batch recalls and manual sorting because it enables virtual inspections even after parts have been dispatched.

Without the need for human sorting activities or batch recalls, manufacturers can totally virtualize new inspections, define completely new features, and update the inspection specifications for existing features. In the event of a quality issue, this can help manufacturers quickly and simply identify the problematic parts and take the necessary corrective action, saving both time and money.

Manufacturers can also benefit from being able to perform retroactive inspections by seeing patterns or trends in their production processes. They can detect possible problems or areas for improvement by analysing the information gathered from prior inspections and taking proactive actions to rectify them.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.