Hexagon’s Manufacturing Intelligence division announced the release of HxGN Production Machining, a new suite of software developed to empower machine shops to achieve operational excellence in the manufacturing of discrete parts, tools, and components with machine tools at any scale, from one-off prototypes to volume production, and across industries ranging from medical to aerospace and beyond.

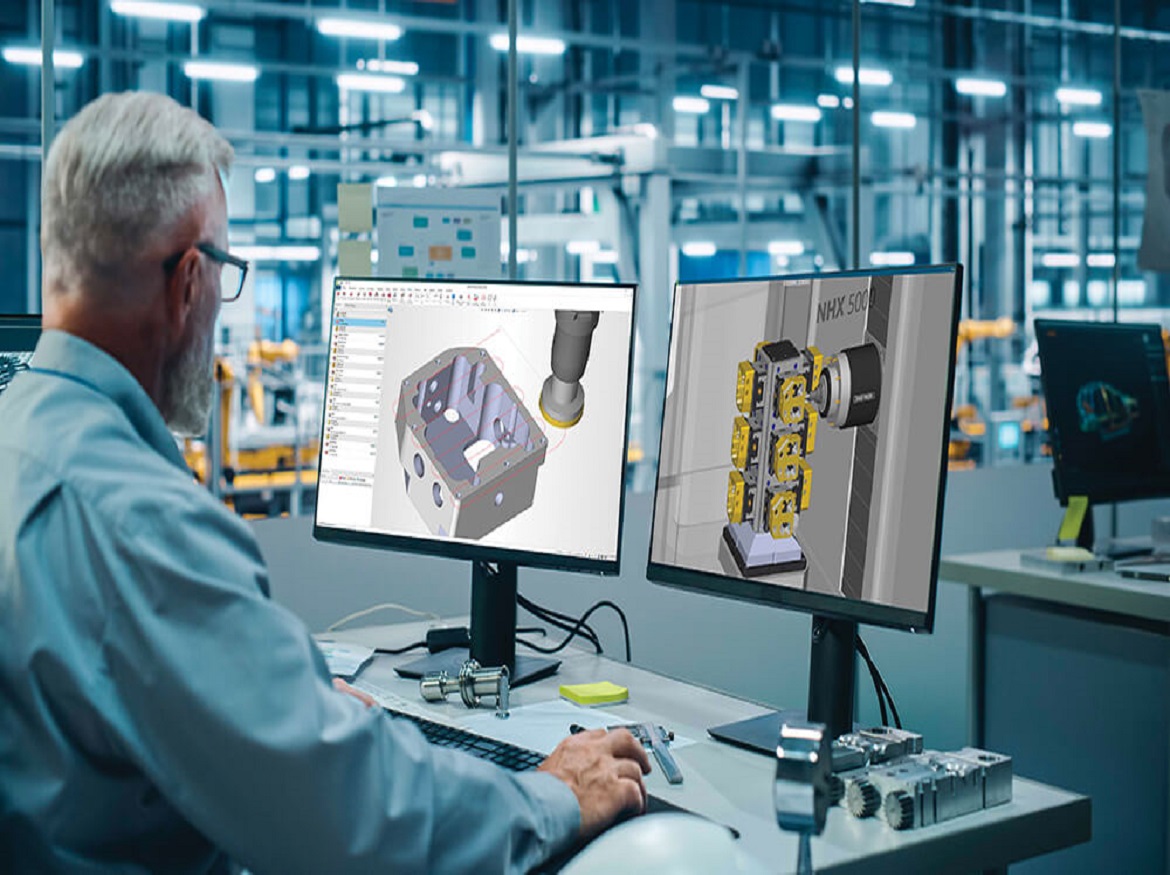

Capabilities of the suite include CAD (computer-aided design) for manufacturing and design review, CAM (computer-aided manufacturing) for CNC (computer numerical control) machine-tool programming, process simulation and G-code verification and optimization, shop-floor production intelligence, and automation and collaboration powered by Nexus, Hexagon’s digital-reality platform. Central to the company’s Machine Shop Excellence solutions, the suite includes significant automation and innovative technologies that help manufacturers achieve highly efficient utilization of material, cutting tools, and CNC equipment, and capture and consistently apply a shop’s best practices.

The HxGN Production Machining suite will integrate common workflows to help teams reduce errors and eliminate redundant tasks at every stage, from job quotation and design review through production, quality assurance, and product delivery. By offering a suite of connected products from the Hexagon ecosystem, manufacturers benefit from simplified procurement, implementation, and support. The suite’s flexibility makes it suitable for shops of any size, all types of CNC machinery, and any discrete part and material from one-off prototypes to high-volume production runs.

“The HxGN Production Machining suite helps shops of all sizes run their businesses more productively by providing a robust software tool set within a connected and intelligent digital workflow that helps teams get it first time right. Using the principles of model-based manufacturing and the automation benefits of artificial intelligence (AI), we are helping our customers achieve greater operational excellence,” said Chuck Mathews, general manager, of production software at Hexagon.

“Innovations within the suite include our new CAM system, ESPRIT EDGE, which combines the DNA of Hexagon’s EDGECAM and ESPRIT software with powerful digital twin and AI technology.”

Parth Joshi, chief product & technology officer at Hexagon added: “Through our suites, we refocus innovation on what matters most to customers, be that in a single product or leveraging data across workflows. Our cloud-based Nexus platform supports future developments that will simplify collaboration and consolidate job data so teams can improve efficiency and quality as they run jobs through their shops from quote through final delivery.”

Preparing jobs for CNC programming is easier with tailored design-for-manufacturing tools developed to accelerate the transition from planning to production. Hexagon’s DESIGNER software accepts CAD data from any vendor and helps manufacturers easily visualize and analyze part model geometry. The software also helps utilize product manufacturing information (PMI), such as tolerance, surface finish, and material data. The suite is designed to preserve this valuable information across the digital thread to streamline production.

Interoperable with DESIGNER, Hexagon’s trio of CAM systems for production machining can program any machine tool, including multi-axis, mill-turn, multi-tasking, Swiss-type, and wire EDM machinery. The software applications, including the widely used EDGECAM and ESPRIT, and the new ESPRIT EDGE, provide a broad spectrum of machining cycles, programming for on-machine measurement, robust automation tools, machine-optimized G-code, and the use of AI to automatically generate collision-free positioning between cutting zones.

Hexagon offers extensive CNC program simulation and verification capabilities to avoid collisions and optimize code for more advanced machinery and complex operations. From the CAM system, machine-specific G-code programs are sent to its NCSIMUL software, which incorporates the entire machining environment to generate a digital twin of the machinery, part, and processes for cycle-time optimization, set-up revision, and program certification.

New production intelligence tools connect with machine tools to provide real-time insights and asset condition monitoring, as well as to support data-driven planning, quoting, and continuous improvement. Created by Hexagon partner Datanomix, Automated Production Intelligence software automatically captures data on machine performance and offers mobile machine-tool status alerts that enable lights-out machining and a high level of automation. By collecting job data, shops of any size can generate more accurate quotes using information about the past performance of machinery for identical or similar jobs.

High volume and precision manufacturing operations can implement closed-loop quality capabilities from the suite, applying series metrology data to predict when parts will begin to fall out of tolerance and automatically perform tooling offsets due to normal tool wear and tear. Hexagon’s Intelligent Machine Control (IMC) software uses statistical process control to update the CNC controller directly, eliminating guesswork and ensuring that manufacturers won’t need to rely upon staff to manually calculate offsets and enable lights-out production.

HxGN Production Machining is available now globally from Hexagon and approved partners. A webinar series detailing how manufacturing challenges are solved with HxGN Production Machining can be accessed at go.mi.hexagon.com/2023/IntroToPS/WebinarSeries. Learn more about Hexagon machining technologies at hexagon.com/products/product-groups/computer-aided-manufacturing-cad-cam-software.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.