Extol & Axiom Too CMM Case Study

The Extol, a shop floor-hardened CMM that Aberlink has introduced, performs quick, accurate, and repeatable inspections in even the most difficult environmental settings. It also has an unusually small footprint, enabling the CMM to be placed where it is most needed: on the shop floor.

Hi-Spec Precision Engineering Ltd., founded in 2004 by Darren Grainger, a highly experienced draughtsman and machinist, has grown from a modest start-up business to an established company specializing in custom machined components and assemblies. Hi-Spec, based in Market Overton in the center of Rutland, combines knowledge, expertise, and abilities to guarantee that its goods are produced and delivered in accordance with the highest standards.

In order to provide engineering solutions for the current market, the company combines modern production technology and automation with traditional methods and practices. It offers its clients a full range of services, from product design and prototyping to the production of one-off, small, and large batch production runs.

Significant investment has been required to keep up with the needs of a developing sub-contract engineering business, according to Darren Grainger. “Every new investment in capital equipment has to be quick and easy to learn, and certainly exhibit time-saving benefits,” he says. Due to the cost reductions and the ongoing difficulties in finding qualified candidates, we have recently invested in automation in our machining cells. Although buying British is always good, it isn’t always possible. You diversify your machining capabilities across a variety of technological platforms in order to weather economic downturns and meet both present and future client demands.

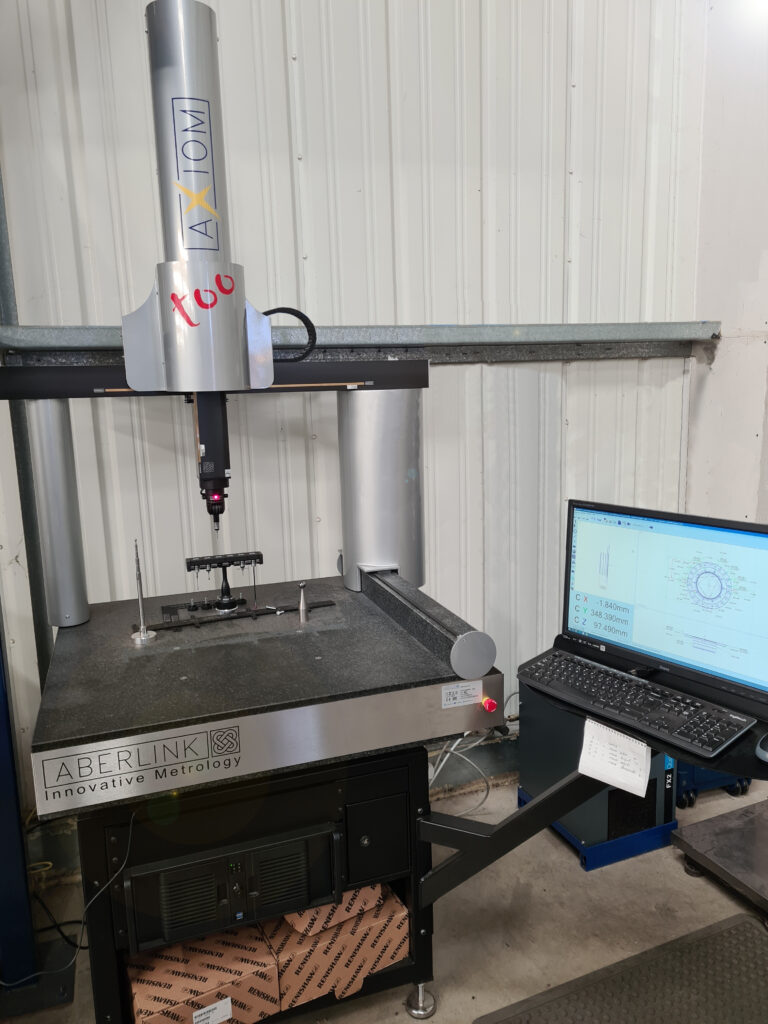

After more than ten years of owning a modest manual CMM and a more recent purchase of an articulating arm, it was clear that some complicated machined elements required a higher level of CMM capacity. A superior CMM was sought after, one that could exhibit the same quick and simple learning capabilities as the machine tool investment. Once more, Darren: “Customers now anticipate receiving CMM inspection reports with their items. We instantly checked the internet because we were aware of the metrology constraints with what we already had, and Aberlink was among the results. I went to a demonstration expecting to purchase another manual CMM with the most recent CMM software package, but it became clear from the demonstration that purchasing a CNC CMM would be a better investment for us. The ability to measure many parts with a single setup and to quickly prepare an inspection program with all dimensions was a revelation. Aberlink’s upfront pricing strategy was a breath of fresh air in addition to being simple to use, British-built, and manufactured. I could verify their costs on their website before I pursued the question.

The decision was reached to purchase an Axiom Too 600 CNC CMM with a fully automatic indexing probe head and probe changing rack after the demonstration at Aberlink in Gloucestershire. As compared to Aberlink’s smaller shop floor Extol CNC CMM, the larger measuring space would be future-proof for any demand to measure larger parts. Following the thorough 2-day training course, the Axiom was also installed four weeks later, and the full potential of having this modern CMM was rapidly realized. In the first few days, Darren says, “we were writing programs and loading many parts so they could be measured totally automatically while we maintained other computers running. We rapidly reached a bottleneck since there were two or three tasks that required to be inspected simultaneously on the new CMM while we were still waiting for one to be broken down. The shop floor CMM I had seen during my demo came to mind when I considered where we required the extra CMM capacity, so I got in touch with them once more.

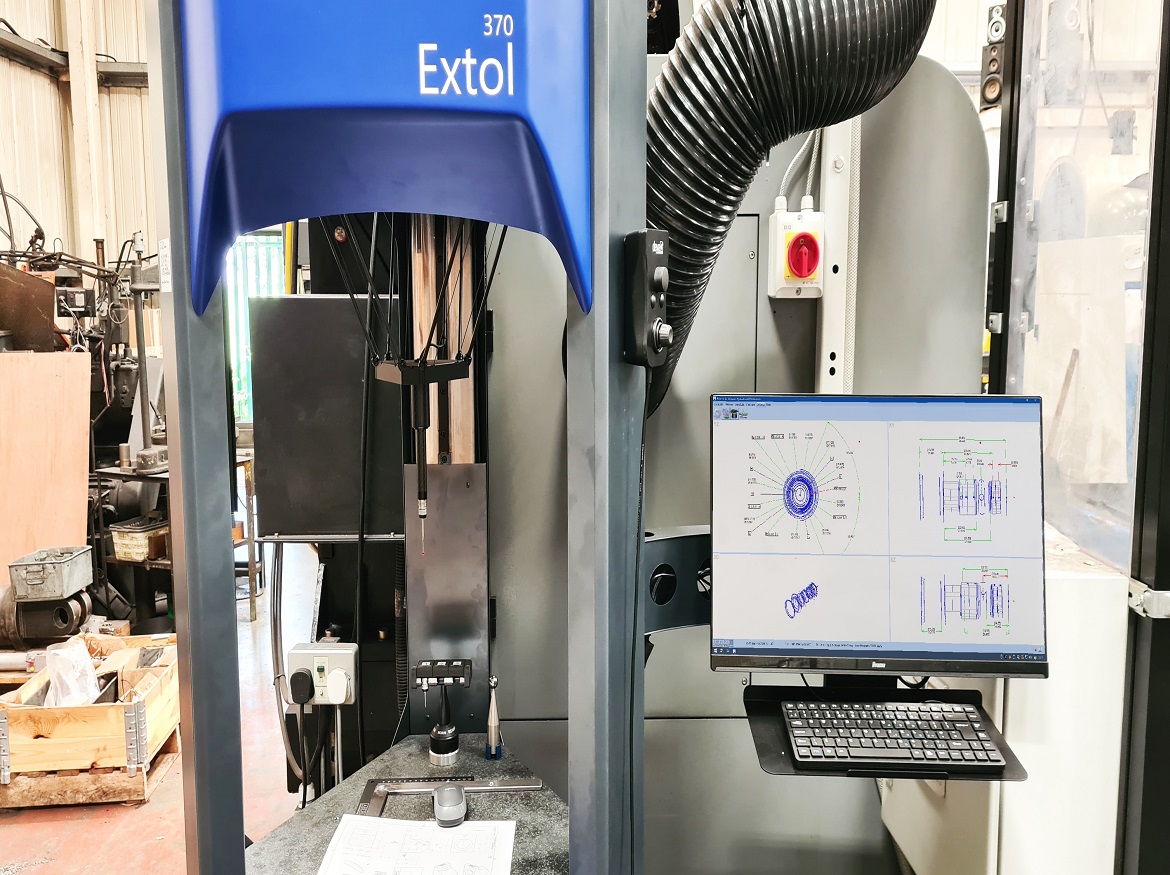

Darren placed an order for a second machine after realizing that the Extol CNC CMM was the solution for putting shop floor CMM measurement where it was needed. Within two weeks, it was delivered, installed, calibrated, and ready to start measuring components. On the shop floor, measurements and verifications were being done on parts created in the automated machining cell. About the second CMM purchase, Darren had the following to say: “The Extol CNC CMM came and was installed and turned on within a few hours of delivery. We rapidly had it configured and doing in-process checks for one of the parts running on our VMCs. Over 40 dimensions were automatically checked without operator assistance in a matter of minutes, which is a victory in my book.

“With purchasing the Axiom too CNC CMM, and then the Extol CMM for the shop floor, we have altered the way we verify our part quality from our automated production cells,” says Darren in summarising his experience. Both of these incredible pieces of equipment—the Extol examines what’s coming off the machines in the production cell and the Axiom validates batch manufacturing and provides inspection reports. Aberlink is the best option for us, and the pricing transparency, presentation, and personnel we saw in Gloucestershire have all convinced us of this. I would not hesitate to suggest Aberlink to anyone looking to upgrade their CMM capabilities or make their first CMM purchase.

The Extol is a full shop floor inspection system that is given as a turnkey solution to meet the most rigorous measurement needs. It was designed and manufactured by Aberlink, the largest UK-owned manufacturer of coordinate measuring machines.

Aberlink takes pride in being the only significant metrology manufacturer to offer equipment with free software upgrades for the duration of the machine and zero annual software maintenance contracts. This translates to very low ownership costs and a quick return on investment.

Customers who are unable to visit a local demo center can now request remote online demonstrations for the whole range of CMMs, measurement software, and accessories from Aberlink.

Credits: Aberlink

Click on the following link Metrologically Speaking to read more such Case Studies on Metrology.