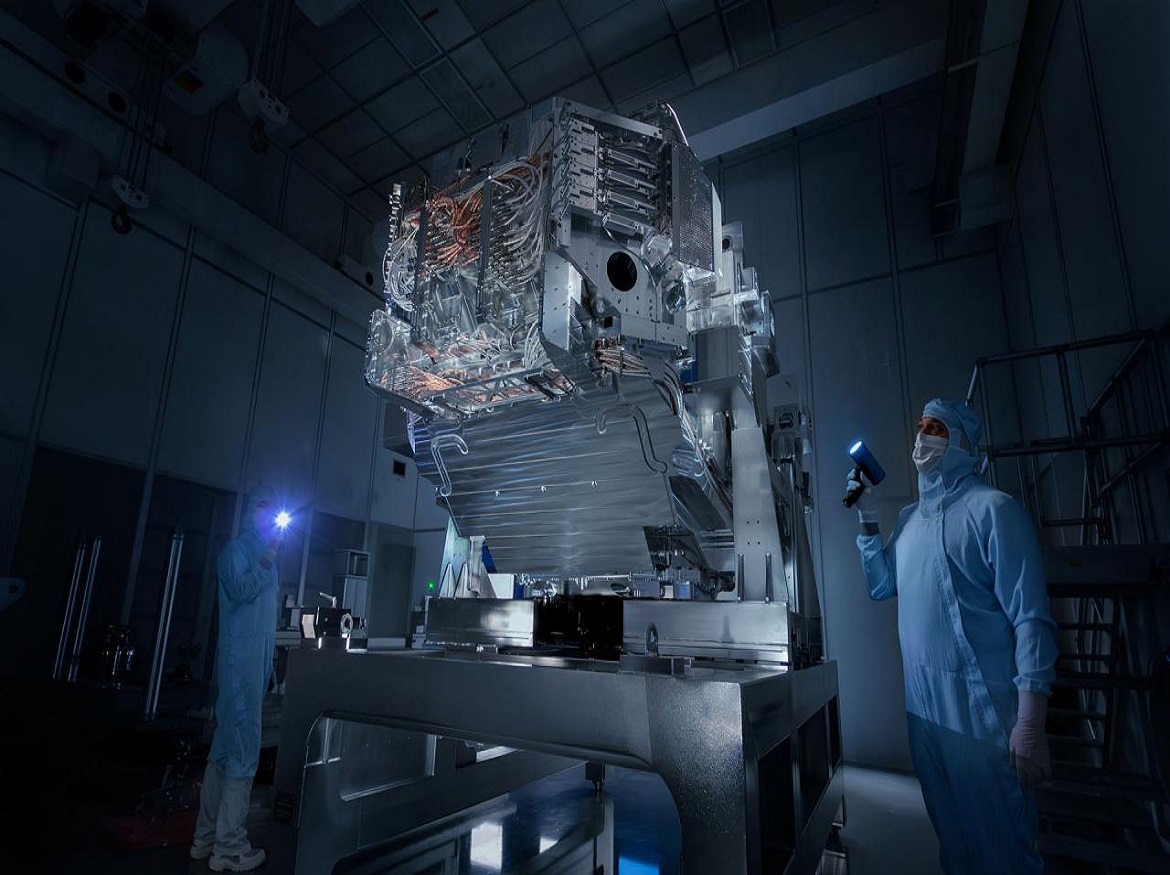

The worldwide unique High-NA-EUV lithography sets new standards for the production of state-of-the-art microchips. ZEISS has developed and manufactured the optical system as the heart of this new technology. The first machine for the High-NA-EUV lithography was recently delivered by the strategic ZEISS partner ASML. The first microchips are set to be produced in series from 2025.

- High-NA-EUV lithography enables a three times higher transistor density on the microchip

- At the heart of the technology is the world’s most precise optical system from ZEISS

- Development of High-NA-EUV lithography builds on a strong European partner network

Oberkochen, Germany | 30 January 2024 | ZEISS Semiconductor Manufacturing Technology

Whether it’s about artificial intelligence, autonomous driving, smart cities or the Internet of Things: the groundbreaking technologies and developments of the future will require enormous computing power – with ever more effective microchips. Together with its strategic partner ASML, the Dutch manufacturer of lithography systems, the ZEISS Semiconductor Manufacturing Technology (SMT) segment has now created the basic prerequisites for the production of integrated circuits at a new level. With the so-called High-NA-EUV lithography, significantly smaller structures can be realized on the carriers of the microchips – the wafers – and thus even more powerful, energy-efficient and cost-effective chips can be produced. The first series production using the new technology is set to begin in 2025.