Optimised for post-process inspection of completed parts

High-speed Inspection System for Additive Manufactured Components

• Simple optical scanning technology minimizes operator training while providing accurate 3D scan data for GD&T and form measurement

• Large measurement volume designed to match build volume of industrial 3D printers; optimized for additive manufactured components

• High-speed acquisition (under a minute for 360° scans of regular, non-occluded components)

• Designed for additive manufacturing workflow integration; compatible with industry-standard data formats and networking protocols

• Utilises Taraz Information-Rich-Metrology (IRM) software to deliver unmatched scanning cycle time and surface coverage

• Available as a turnkey system, integration component, or licensable reference design

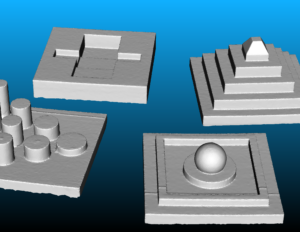

The TZF1300 is a full-featured scanning system designed to complement industrial 3D printing systems, providing quality control and calibration/feedback data into the 3D print environment. The system uses advanced, camera-based optical metrology and is optimized for the inspection of additively manufactured parts, greatly enhancing speed and versatility.

Scan data from the TZF1300 family can be used in industry-standard point cloud processing software, either for analysis, reverse engineering, or process development. TZF1300 is a member of the TZF family that offers options on measurement volume, feature accuracy, and scanning speed. The family is also supported with a bespoke design service, allowing the design to be optimized to a specific requirement, or to be fine-tuned to match a specific printer.

Technology

The TZF1000 family breaks the mould of optical scanners, moving away from the traditional approach of the fixed triangulation schemes typically used in typical laser, fringe projection, or structured light scanners. Instead, a “variable triangulation” technology is used, allowing far greater freedom in generating the different viewing angles required to fully inspect an object. By also eliminating the projection systems required for fixed-triangulation scanners, the cost is eliminated – and acquisition performance is greatly enhanced. These enhancements are enabled through the use of Taraz’s innovative IRM software. Using artificial intelligence techniques to optimize the measurement process, IRM delivers cost savings and speed benefits – while retaining accuracy.

Applications

Many applications benefit from the TZF1300’s capability, including:

| Quality Assurance | The TZF1300 provides an accurate scan of the manufactured component and can automate comparison of the part’s form to CAD – or can be scripted with industry-standard inspection software to instigate formal GD&T inspections. |

| Reverse Engineering | For existing parts lacking design data, the TZF1300 can provide a detailed scan for reverse engineering in seconds. |

| Part Identification | When unpacking a build volume with mixed components, the TZF1300 will confirm the identification of a part – and optionally provide a pass/fail indication. |

| Printer Calibration | Knowledge of parts manufactured enables optimization of print processes, yielding increased accuracy for production parts. Taraz Metrology can assist with the design and manufacture of bespoke artifacts designed for printer calibration. |

| Process Compensation | For multi-stage processes (such as finishing, or the curing of “green” parts) the process can introduce significant change from the as-printed geometry or dimensions. TZF1300 provides feedback on the stage-by-stage component geometry, allowing pre-compensation of the build job – and enhancing yield. |

User Interfaces

The TZF family is intended for use alongside high-capacity printing systems in the industrial environment. IRM software features a user interface designed for the printer operator; when integrated with the printer’s build manager software, it offers the user a choice of parts that are due to be unpacked from the printer. When the user selects a part, the IRM software will prompt the user to load it into the inspection volume, while reading the associated CAD file – and PMI / GD&T data where available. Scanning and inspection (which can be scripted with industry-standard inspection packages) are then automated, with user feedback provided throughout the process.

Finally, as the part is unloaded, the software can print an identification label for the part – including a pass/fail for final quality inspection if required.

The software has three operating modes:

User – a simple interface with the ability to select parts, start a scan, and see results

Developer – adding the ability to store data for offline analysis, and to scan parts without CAD – for example for reverse engineering or process development applications

Administrator – with the capability to perform all configuration, set up batch jobs and policies, perform annual calibration or system checks, etc.

In addition, remote operation modes are available, providing options for training, application, and product support.

Supply Formats

While the TZF1300 is a powerful scanning system capable of operation in a bench-top format, it is intended to be capable of use as a system component for integration into end-user equipment. Taraz Metrology can provide the TZF1300 as a reference design supported by a bespoke design service – as a component for integration – or as a complete system, ready for use.

To know more, contact Taraz Metrology.