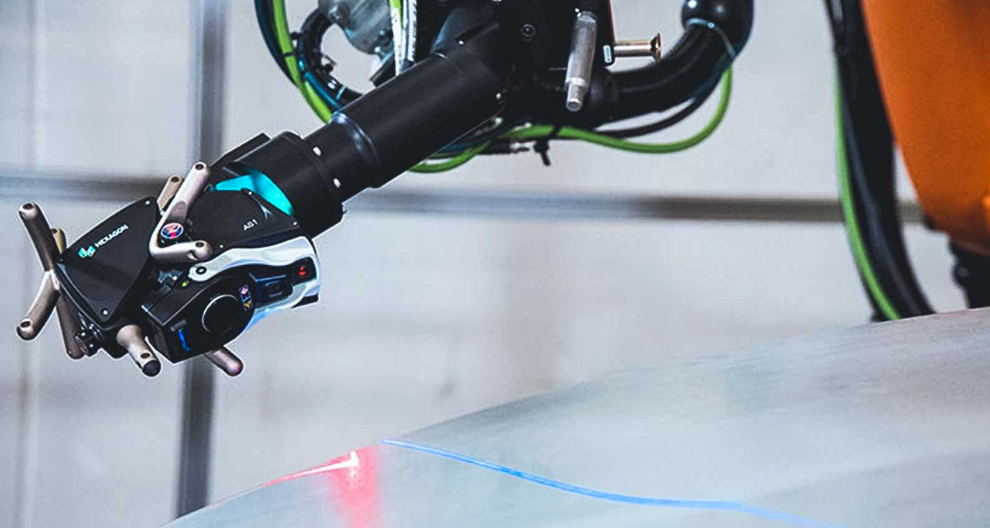

Hexagon’s transformative solution, HxGN Robotic Automation, enables operators to accelerate autonomous quality assurance.

This intuitive, flexible and scalable robotic control software was designed to simplify programming for automated measurement and inspection applications. HxGN Robotic Automation makes it easier than ever to acquire data through smarter manufacturing processes, orchestrating the sensors, software and robotic equipment of an inspection cell from a single interface to make automated measurement more accessible, more efficient and more reliable.

HxGN Robotic Automation is a hardware- and software-agnostic toolset that integrates seamlessly with your existing workflows or technologies. This enables manufacturers to equip greenfield factories or retrofit existing production lines with state-of-the-art autonomous inspection cells.

By easily integrating new sensors, software and robotic equipment, solutions scale to different applications as needed and accelerate time to market by eliminating historic bottlenecks. This new software can work with everything from small to extra-large part sizes, from simple single fixed robot cells to complex cells and a variety of different applications.

“We have reduced the time required to programme robotic inspection from several days to just four hours using the new software, so we can be ready and waiting to inspect a new vehicle as soon as we want to begin production,” said Martin Jehlička, Chief of Measurement Centre at ŠKODA AUTO. “Robotic automation and Hexagon’s high-speed laser scanning systems have already halved the inspection time for parts and sub-assemblies, and installing these automated inspection cells on the production line is fundamental to our Industry 4.0 strategy of making data available and actionable so quality trends can be identified quickly, or in some cases automatically corrected.”

With HxGN Robotic Automation, metrology and robotics professionals can multiply their efforts in improving quality assurance, driving consistent quality and consolidating metrology data throughout manufacturing lines. Rich, real-time, in-line metrology data could fuel future machine learning systems to optimise designs, parts and production processes and create increasingly autonomous, self-correcting production lines.

Robust offline programming makes it possible to repurpose or hone metrology cells with minimal production downtime through HxGN Robotic Automation. This solution maintains more agile manufacturing operations and enables new cell-based manufacturing models that are based on achieving product customisation and speed without sacrificing the efficiencies associated with volume production.

“Truly smart manufacturing needs swift, accurate and accessible measurement data, but many robotic inspection systems are costly, complex, closed systems that are incompatible with manufacturer’s chosen tools and inaccessible to non-specialists. HxGN Robotic Automation is built around openness, so that manufacturers can swiftly and seamlessly future-proof entire manufacturing lines for robotic inspection,” said Stephen Graham, President of Metrology and Production Software at Hexagon’s Manufacturing Intelligence division.