Automated Shop Floor Scanning, Measurement, Inspection, and Reporting

Stuttgart, Germany, May, 2022

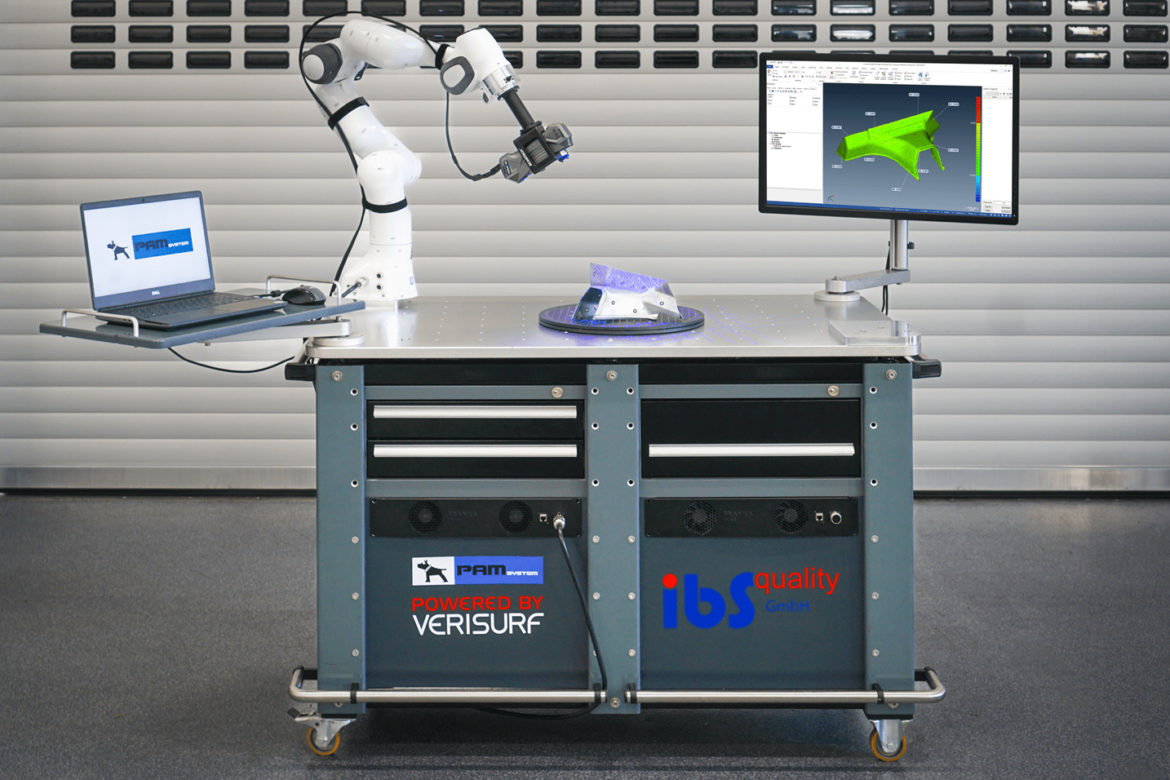

IBS Quality GmbH launched, the new PAM-System (Portable Automated Measurement System), a portable cobot-based 3D scanning and measurement solution, at Control, Stuttgart, Germany, May 3 -6, Hall 3, Stand 3314. The launch is in collaboration with Verisurf Software, Inc., and its integrated 3D measurement software for automated quality inspection, reporting, scanning, and reverse engineering.

The PAM-System is a portable scanning, measurement, and inspection solution that uses cobots (collaborative robots) to augment repetitive user routines while adding flexibility, dexterity, and accuracy. All hardware (including fixtures for sensor attachments to the robot), software, installation, service, and support are included with the comprehensive system. The entire solution is self-contained on a specially designed inspection cart that can be easily rolled from the quality lab to the shop floor. The PAM-System can be used for first article inspection, volume production inspection, reverse engineering, and prototyping,

“We have designed the best of today’s robotic, scanning, measurement, and inspection automation technologies into a single mobile solution; one that meets the practical needs of job shops and OEM manufacturers adapting to the realities of Industry 4.0,” said Philipp Schmid, IBS Quality GmbH.

The PAM-System includes robotics automation from 11 Dynamics, 3D measurement, inspection, and reporting integration with Verisurf Software, and a choice of leading 3D laser scanner brands or other scanner technologies.

The integrated Verisurf 3D Scanning and Inspection application is built on a CAD platform and is rooted in Model-Based Definition (MBD). Inspection plans are easily created by importing any CAD model, using drawings, a golden part, or key features. Inspection plans can be used across the manufacturing enterprise on any CMM, providing repeatable process control. “The Verisurf workflow enhances productivity and enables repeatable process control, which is a key tenet of QA; the automated PAM-System supports both,” said Nick Merrell, executive vice president of Verisurf.

For more information about the PAM-System contact:

IBS Quality GmbH

Philipp Schmid

p.schmid@ibs-quality.de

Verisurf EMEA

Kai Gaertling

kai.gaertling@verisurf.com

Verisurf USA

sales@verisurf.com

About IBS Quality

IBS Quality GmbH is an industrial measurement technology service provider. In a climate-controlled measuring laboratory, accredited according to ISO 17025, IBS Quality provides solutions to measuring tasks using non-destructive computed tomography and precise 3D coordinate measuring technology. Onsite services are also provided via work contract or as a temporary worker as approved by the Federal Employment Agency. The Company also supplies hiring and placement services of specialists and executives in the technical, industrial, and commercial sectors. IBS Quality applies its extensive hands-on experience in measurement, inspection, and quality reporting to the development of automated 3D scanning and measurement solutions, including the new PAM-System. http://www.ibs-scantech.de

About Verisurf

Verisurf Software, Inc. is a measurement solutions company, committed to delivering advanced surface analysis, quality inspection, assembly guidance, and reverse engineering. Verisurf products and processes are vital to maintaining a digital thread between design, engineering, manufacturing, and finished part validation. Based on a powerful CAD platform, Verisurf is committed to Model-Based Definition (MBD), open standards, and interoperability with all coordinate measuring machines and CAD software. Verisurf solutions help manufacturers produce higher-quality products in less time. For more information about Verisurf, visit www.verisurf.com.