The heavy construction equipment manufacturing industry originated in the late 1800s and has since undergone significant advancements. Ensuring high-quality manufacturing is crucial, as these machines must operate reliably and durably in challenging environments.

Steel Heavy Construction Machinery Manufacturer

SSAB is a global leader in high-strength steels and related services. This Swedish steel company has established itself as a pioneer in the steel industry with a vision of creating a stronger, lighter, and more sustainable world.

SSAB manufactures a variety of steel products, including their proprietary Hardox material, known for its exceptional strength and durability. The parts they manufactured are typically large steel components used in heavy machinery and construction.

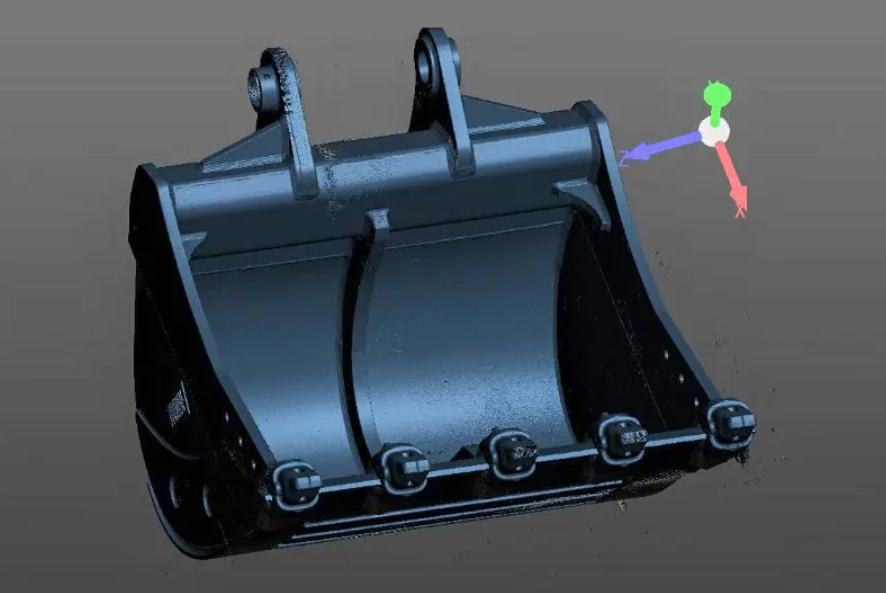

Feature of the Excavator Bucket to be Measured

The part to be measured in this case is a large excavator bucket, which may endure significant wear and impact due to its direct contact with materials. The shape of the bucket is crucial as it influences the stress conditions and the loading efficiency.

SSAB’s main application is in product development, where accurate scanning is crucial to capture all dimensions, model them precisely, and proceed with manufacturing. Accurately measuring is essential for manufacturing buckets with long lifespan and excellent working efficiency.

Measurement Challenges

Width and Depth: Measure the inside height, width, and depth to ensure the overall capacity. The cutting width should be measured to ensure the effective working of the bucket.

Compatibility with Bucket Bushings: Measure the diameter of the upper pin hole and the diameter of the lower pin hole to ensure compatibility with attachments. The distance from pin hole center to pin hole center is crucial for alignment.

Importance of Accurate Measurements: These measurements are essential for ensuring the manufactured bucket fits properly and functions as intended.

Limits of Previous Measurement Methods

Previous measurement methods, such as manual measurements and traditional scanning techniques, have several limitations. Manual measurements are time-consuming and prone to human error, while traditional scanners may not provide the required accuracy or may take too long to complete the scanning process.

Additionally, external conditions, such as temperature fluctuations and unstable environments, can further compromise the accuracy and reliability of these methods.

Scantech’s 3D Solutions for New Product Development Process

To address these challenges, SSAB turned to Scantech’s advanced 3D scanning solutions, the wireless optical 3D measurement system NimbleTrack. It is designed to measure small to medium-sized parts with high precision and efficiency.

Scantech’s NimbleTrack 3D scanning system allows for the scanning of large bucket without sacrificing accuracy or speed. The process involves moving the equipment to the job site and then beginning the scanning process.

NimbleTrack has precisely captured its full-field 3D data and the dimensions of the excavator bucket, focusing on key aspects such as width, depth and pin hole diameters. The system ensures high-quality mesh results, which are then converted to CAD models for product development.

This helps engineers analyze and understand the design and functionality of existing products, using this data to replicate and improve the product, ensuring compatibility and performance.

The detailed 3D model also allows designers to visualize and test the product in a virtual environment before moving to physical production, saving time and resources.

Benefits of 3D Solutions

Scantech’s 3D solutions offer several benefits for SSAB:

Wireless Freedom: With powerful on-board chips and built-in batteries, its 3D scanner and optical tracker are completely wireless, providing true freedom of movement. Operators no longer need to search for a power supply, deal with tangled wires, or spend a long time setting up the 3D scanner.

High Accuracy: Thanks to its robust algorithm and stable structure, it ensure a high precision of up to 0.025mm. The Nimble Track system meets the stringent accuracy requirements, ensuring precise measurements.

Efficiency: The scanning process is efficiently completed thanks to its high measurement rate of 4,900,000 measurements/s and non-target 3D scanning, significantly boosting productivity.

This quick turnaround allows operators to swiftly move on to the next task, minimizing delays and maximizing operational efficiency.

Adaptability: The system excels even in harsh external conditions, consistently maintaining stability and accuracy. Whether it’s high temperatures, dust, or vibrations, it ensures reliable performance on the shop floor without compromising precision.

Quality: The high-quality mesh results from the scanning process enable precise CAD modeling, which in turn enhances product design and manufacturing.

This accuracy ensures that every detail is captured, allowing for better-fitting parts, improved functionality, and reduced errors in the production process.

Conclusion

With NimbleTrack, the team quickly scanned components, enabling precise designs and rapid prototyping. The ability to digitally visualize the component before manufacturing saved time and energy, streamlining the production process.

Implementing NimbleTrack brought significant business benefits, leading to greater production output and new market opportunities.