An innovative new measuring method for direct scanning with the Leica Absolute Tracker ATS600 was created in response to the specific requirements of an aerospace customer.

Since the introduction of the Leica Absolute Tracker ATS600, the system’s revolutionary direct scanning capability has opened up a variety of new metrology-grade inspection applications. Measurements that were previously impractical can now be carried out easily, allowing for greater quality control over large-scale products than has ever been possible.

A significant aerospace customer who wanted to switch from their present measuring method—which entailed a tracker and reflector measurement process—to direct scanning with the ATS600 contacted Hexagon’s laser tracker team in 2022. In their previous procedure, an operator would bring a reflector to each of the surface points on the part in order to take a measurement. Only once the reflector arrived at the coordinate were points recorded. The size of the part necessitates the use of a scaffold and safety apparatus, both of which had to be moved around several times due to the typical size of the parts being measured. The main driver for looking into the switch to direct scanning was how time-consuming this process was.

Although Hexagon has been forthright about the convenience of direct scanning coming at the cost of diminished precision when compared to reflector inspection, the business was still concerned about whether the performance of the ATS600’s direct scanning would meet their tolerance criteria. It was decided to conduct a round of testing using a demonstration unit and the company’s local Hexagon team in order to determine whether or not the reflectorless measurement findings would be sufficient to fulfil their strict aerospace tolerances.

During the anticipated testing, the initial measurements made simultaneously with a reflector and with direct scanning did not produce findings that were consistent. The condition of the surface, which was scratched and marked from a prior manufacturing process, was thought to be the cause of this variability. The local team sought help from Hexagon’s team of laser tracker experts based in Switzerland, where the Absolute Tracker range is created and made since they thought this was more of a variability issue than a true inability to achieve the needed level of accuracy.

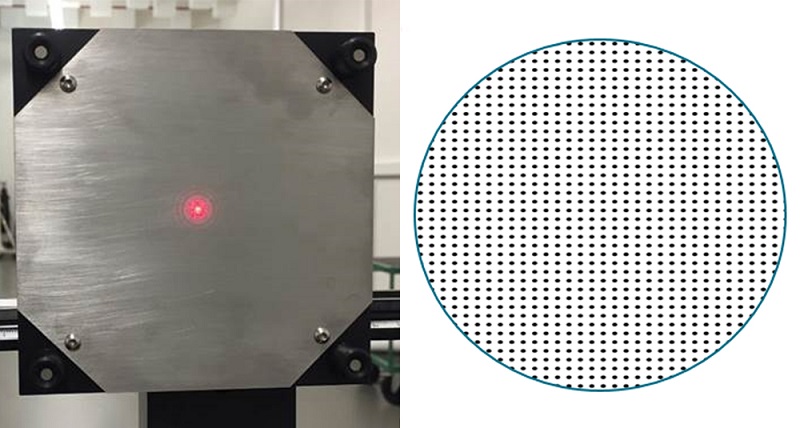

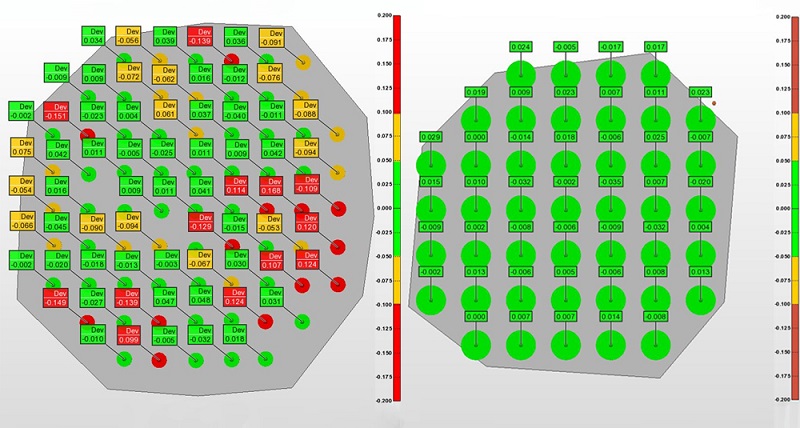

The team started by setting up a series of tests in which a brushed steel plate was measured at various angles (0° to 60°) and distances (2 to 15 metres) from the ATS600. With a 1.5″ reflector, the plate was first measured from every angle and distance, with 21 points collected and utilised to fit a plane. The same variability problem that had been discovered by the local team on site with the aerospace customer was evident in later direct scanning measurements.

After researching the issue, the team came up with a brand-new measurement technique known as surface comparison point measurement. The idea is to take a grid of closely spaced point measurements and compute an average coordinate value for the grid’s centre using those results.

Assume that 100 discrete points must be measured for a specific target object. When the software receives the coordinates of those points, it will automatically generate a compact grid of reflectorless measurement spots surrounding each one. The ATS600 will scan every point in the grid once the user presses “Measure,” then compute a mean value that corresponds to the requested coordinate. By using this method, outliers brought on by material scratches are removed. The recommended grid radius ranges from 4 to 8 millimetres, with the bigger recommended for greater measuring distances as the diameter of the laser beam grows.

Improving accuracy by a factor of two, with repeatability drastically reduced to only 10 microns

In comparison to reflector measurement, the outcome is a reasonably straightforward new measuring approach that provides high accuracy and repeatability outcomes while still giving sizable time savings.

Hexagon’s laser tracker engineers conducted extensive testing, which revealed that this approach may increase accuracy by a factor of two while reducing repeatability to only 10 microns. If clients are also interested in using this new measurement method, they should get in touch with their local Hexagon representative. The new measurement can be simply applied by those metrology software packages providing an interface to the ATS600.

The aerospace corporation that carried out the assessment made an investment in three new ATS600 units based on these findings. Inspection times will be cut in half, from 2.5 hours to 45 minutes, compared to their current setup and warming operations.

The direct scanning technology also guarantees worker safety because it eliminates the need for operating at heights. Additionally, because the ATS600 can perform measurements with and without reflectors, it can continue to perform the automated wing-joining routines that currently use reflectors while also switching to new non-contact scanning inspection routines without requiring multiple technology setups and teardowns.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.