Souvik Mitra of Metrologically Speaking spoke to Mr. Sumit of Autus Metrology to know more about the company. Here is the interview transcript.

About Autus Metrology

Autus Metrology started its journey in Feb 2011 with a team of young, dynamic, and competent individuals together as a team.

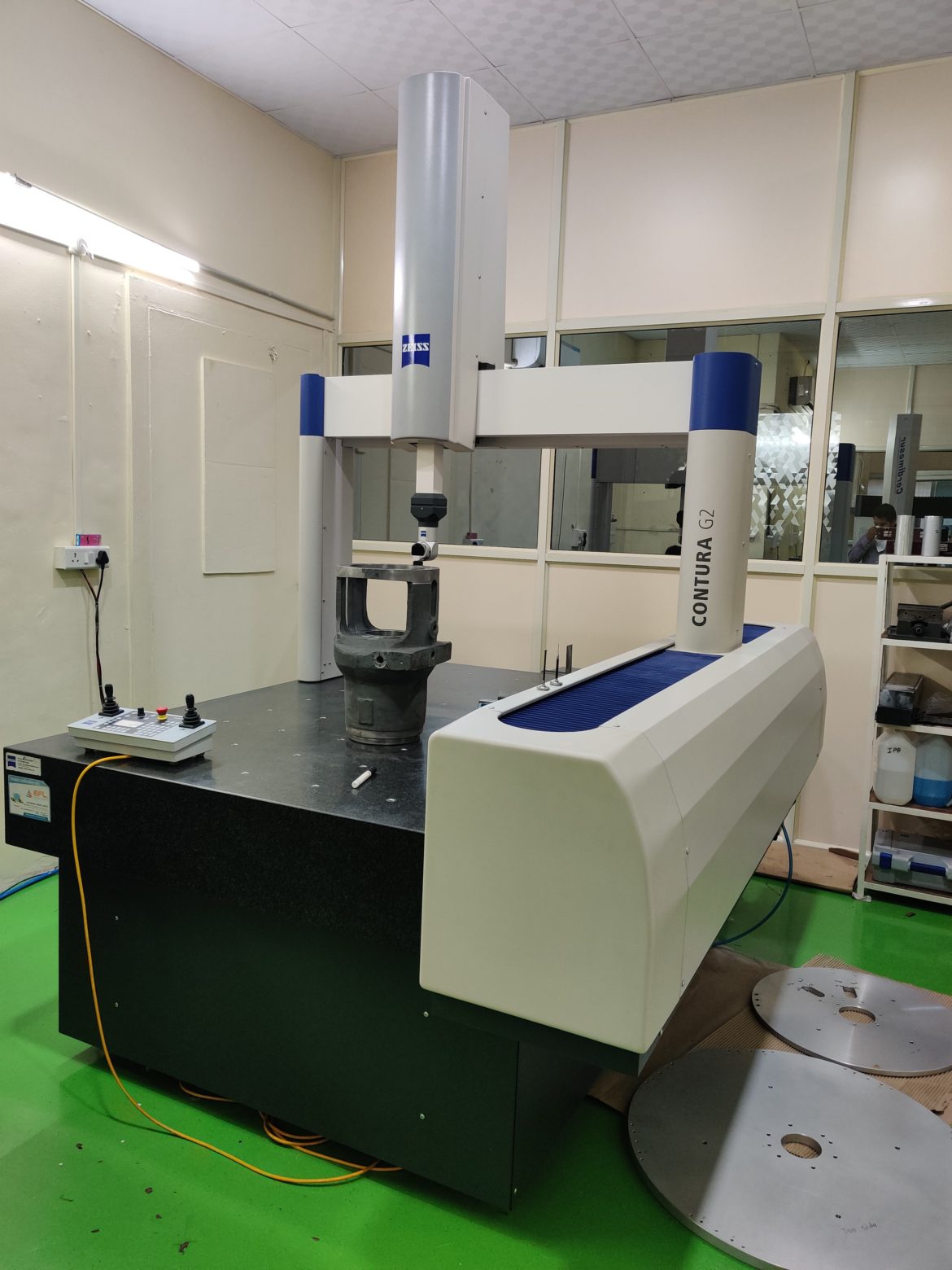

Our engineers have expertise in 3D CMM Inspection, Reverse engineering, 3D modelling and 2D drafting, long-range part inspection with Carl Zeiss CMM’s along with the Blue light scanner.

We provide skilled resources and subject matter experts for design engineering services across diverse industry segments. Over the years, our engineers have managed and supported some of the most demanding and prestigious projects in automotive, aerospace, industrial machinery, medical equipment, and consumer electronics. Our highly competent technical teams work cohesively with the client’s R&D, Quality, Purchase teams, to carve out and then deliver a sustainable work result as a whole. With our Portable services in metrology, we deploy onsite customer-centric solutions along with new product designs and modifications if any.

Please tell us about your company?

Autus Metrology was started in the year 2011 by my father Mr Bajirao Pokarkar. That time we had only one machine with us. Today, we have a total of 7 machines from Fixed Bed CMMs, Contour Tracer, Laser Arm Scanner, Blue Light Scanner, and others. We are also planning to buy other machines to complete our entire metrology set-up and also to provide all services that our customers need under one roof.

What type of customers does your company serve?

We provide Metrology and Prototyping services. Keeping in mind the requirements of our customers, we expanded our services in March 2020 to include a 3D printing facility. Immediately, we were faced with a lockdown due to the pandemic and that slowed down things a bit. Now, we already have a few orders with us for prototyping.

How has COVID -19 affected your business?

During the pandemic, our business was closed due to lockdown, After the lockdown got over for two months we did face challenges due to low production. For the past two weeks, there has been an improvement and now things are running smoothly. We have built a good customer base in the last decade and this has helped our business to quickly recover. I am very positive that after Diwali the market will pick up.

What is your annual turnover and do you see your growth getting affected due to the pandemic?

Our annual turnover is Rupees 1.25 crores. Our peak growth period is during April – May months which this year was a completely nonproductive period because of complete lockdown due to COVID-19. This year we expect to see a dip in our turnover just like businesses all over the world. We have planned to buy a Laser Tracker and if that can be achieved in this financial year, we hope to recover any shortfall in the turnover.

Who are your major customers?

Our major customers are Grupo Antolin, Tata Motors, Fiat, Renault, Mahindra & Mahindra, Renault Nissan, and many more. We cater to mainly Automotive OEMs and Tier 1 and Tier 2 suppliers. We also cater to Aerospace, Textile Industry, Oil and Gas, etc.

What are your plans?

This year, we had planned to open another factory in Kolhapur, Maharashtra. Now, after the pandemic, we have decided to push this to the next financial year. In the future, we plan to open other branches in Bengaluru and then Chennai so that we can provide our services to clients in southern India.

How did you manage the financial constraints during COVID-19?

Even though it has been a tough time during the lockdown, we have been able to take care of our employees. We had to reduce everyone’s salaries but we decided not to let anyone go. Our team is like our family and we wanted the best we can for them. We will reinstate everyone’s salary. Even though we need new manpower, we have decided to hold back on that decision till things go back to normal.

What are your thoughts on the ‘Make in India’ policy of the government?

I believe it is a very good policy as our customers will also support us because of this policy. With the ban in imports, we can see the growth of Indian industries in the coming days.

What do you think about the future of the Metrology Industry in India?

Due to the pandemic, many companies had stopped production so this is challenging. The companies that could continue their production, are in a much stable position. We received regular payments from OEMs and Tier 1 vendors throughout this time, smaller vendors are facing a financial setback and were not able to release their payments. Overall, things will start picking up soon and the industry as a whole will see a positive change.