k-Space Associates, Inc. is excited to announce that they recently received a large order for solar panel edge profile metrology systems.

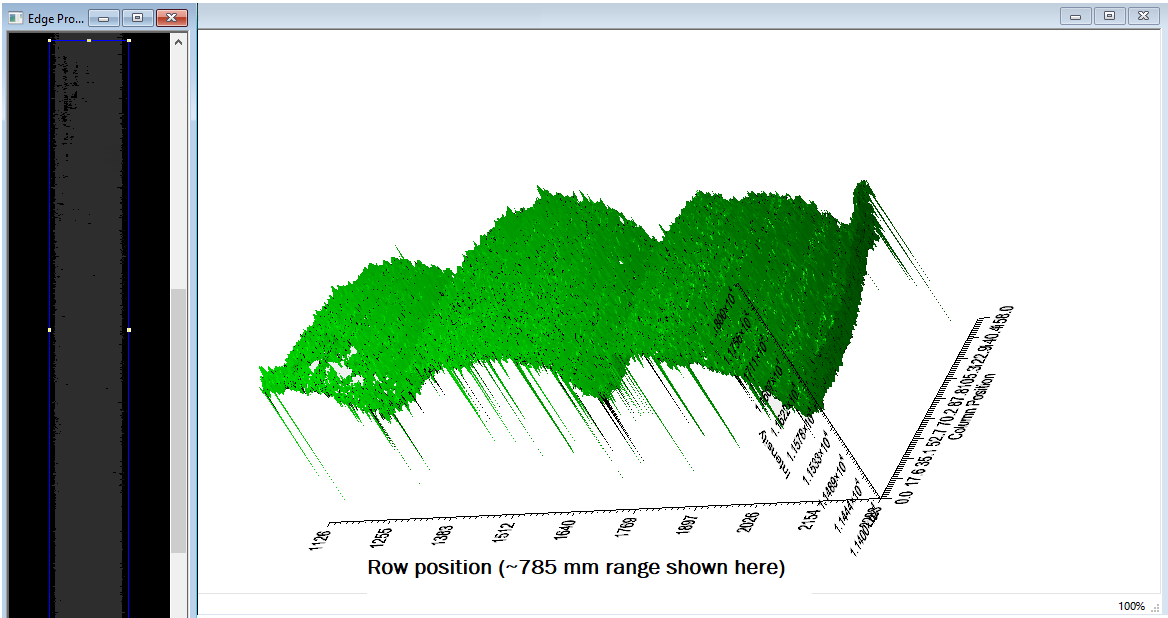

The non-contact, inline glass metrology tool measures the edge of the solar panels using proven optical triangulation technology and 405nm laser technology to resolve glass panel edge profiles. The system measures edge radius and glass sheet offset, and it detects edge defects (chips, cracks), all in real-time and with extremely high spatial resolution.

This tool helps manufacturers to improve their yield through process control and by detecting issues, such as the need to change or adjust grinder wheels. The data comparison in the software allows for in-process panel validation and quality control. Also, early identification of edge defects reduces the chance of glass breakage and the potential yield losses further down the line.

Darryl Barlett, CEO of k-Space Associates, Inc., states, “We are excited to offer tools that combine advanced sensor technology with our engineering expertise into a total package that includes hardware, software, and database capabilities and integrates into the customer’s existing system. These tools will ultimately save them money and allow them to produce a more consistent product.” For more information on the kSA Panel Edge Profile metrology system for glass, solar, or other panels, please visit https://k-space.com/industrial-metrology/solar-panel-inspection/.