The advantages of a KEYENCE XM Series portable, benchtop coordinate measuring machine (CMM) are being used by Seattle-based Prototype Design Laboratories, a specialist in quick turnaround, high-mix, low-volume machining, to perform in-process part inspection and reduce component lead times for clients.

Prototype Design Labs’ president, Brian Wadey, founded the business in 2017 after working as a senior prototype design engineer and CNC programmer in industries like healthcare, aerospace, and education.

NICHE OPPORTUNITY

Wadey says, “I founded Prototype Design Labs to service the burgeoning research community in the Seattle area, which frequently struggles to find machine shops that can satisfy their exacting criteria. “At first, a large portion of the components we produced were for biological and cell research systems. Nevertheless, since then, we’ve included Xometry work in our mix.

A significant US-based marketplace for on-demand industrial prototypes and production components is called Xometry. Being a Xometry supplier implies accelerating the transition from design to the final component, which is one of the keys to success. Suppliers, like Prototype Design Labs, go to a “job board” where Xometry’s algorithm publishes jobs based on which partners have the necessary tools and expertise to finish the task effectively in the allotted lead time. As a new job becomes available, partners are notified, and the first to accept receives the job.

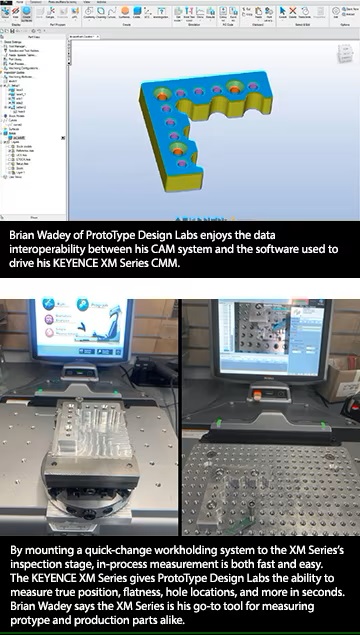

The requirement for a high-level inspection resource was the biggest challenge I had to deal with before working with organizations like Xometry, says Wadey. Although I am familiar with conventional CMMs, the XM portable benchtop CMM from KEYENCE caught my attention due to its affordability, ease of operation, simplicity, and small size. As soon as I saw it, I knew it was exactly what I needed.”

SIMPLICITY AND SPEED

The KEYENCE XM Series is ideal for usage by anyone, wherever in the facility, including the shop floor, as it requires neither CNC programming nor moving parts. The XM Series offers the simplicity of calipers with the power of a CMM. The XM has a portable, free-angle probe that enables measurement from any angle. It also features 3D CAD comparison and export features, temperature adjustment, and on-screen training. Optical technology offers touch-to-measure operability and approach freedom. The XM uses augmented reality to overlay the 3D image on the image captured by the camera positioned on the probe while also displaying measurement data on a live image of the component. With the aid of this function, individuals with no prior CMM knowledge can comprehend measuring procedures with ease. Prototype Design Labs uses its KEYENCE XM Series to capture important measures after machining operations and determine whether adjustments to the company’s CNC machines may be necessary. Because it enables the company to finish items more quickly and achieve speedier turnaround times, this capability offers a lot of value. Wadey may then take on additional work and make better use of his production machinery.

He claims that “the XM offers several choices to facilitate manufacturing and inspection.” It’s a fantastic entry-level option that is quite simple to use and offers self-guidance as you go. Additionally, we may produce reports with augmented images demonstrating the inspection process, and repeatable CMM programs for batch production runs. KEYENCE XM customers can also exchange CMM programs with one another.

IN-PROCESS INSPECTION

The XM, according to Wadey, is perfect for prototyping and in-process inspection. To transport parts on and off the CNC machines and the KEYENCE XM for checking “on the fly,” the company uses specialized tooling, such as the Lang zero-point clamping systems on its five-axis machining centers.

In terms of GD&T [geometric dimensioning and tolerancing], Wadey adds, “The XM is also wonderful, especially when working with softer materials like plastics, which can deflect during milling.” “The KEYENCE XM has a good feature that permits the import of CAD files [such as a STEP or IGES], and the world is heading towards model-based definition. The coordinate system can then be aligned, and any deviations can be checked against the CAD model. The handheld probe for the XM makes the entire process simple. I’ve spent around 35 years working in the manufacturing industry, and I can still clearly recall the days when parts would occasionally take days to pass through the inspection department. Not any longer.

Wadey appreciates that the XM has no moving parts, thus nothing needs to be replaced. There are also no yearly maintenance expenses.

HIGH CONFIDENCE LEVELS

The trust we have in our machined workpieces has increased dramatically since the KEYENCE XM arrived roughly 18 months ago, he claims. Repeatability is crucial in our field of work. In building a program to be used later to check our correction-run components, we can use the XM to check a new part or model. SPC (statistical process control) is used in this way.

Wadey has high respect for KEYENCE’s support, which was unwavering even at the height of the Covid-19 outbreak, thanks to its online virtual service, in addition to the technology.

“Now, if I need help, I just send a file and KEYENCE gives me advice on how to examine a specific feature,” he says. Even with all my experience, you never stop learning. KEYENCE always responds very quickly, frequently in less than an hour. I have nothing but praise for the assistance they provide.

Credits: Keyence

Click on the following link Metrologically Speaking to read more such case studies about the Metrology Industry.