Kitov.ai, a leading company in intelligent visual inspection solutions based in Israel, announces significant improvements to its flagship software platform with the introduction of version 2.7. The latest version brings about enhanced user experience and expanded functionality, offering a more efficient and user-friendly workflow along with increased control options.

Dr. Yossi Rubner, the company’s founder and CTO, highlighted the platform’s evolution: “Since its inception, Kitov.ai’s software has been at the forefront of utilizing AI to facilitate sophisticated quality inspections of intricate components and products. With each update, we’ve made the Smart Planner even more capable. The focus of this latest version is to provide our users with an even greater degree of control, flexibility, and functionality through streamlined workflows and an exceptionally intuitive interface.”

The software suite by Kitov.ai features multiple components designed to enable smart inspection processes. Its improved AI Trainer permits operators without specialized expertise to rapidly gather and label defect data, thus providing a solid foundation for the software’s neural network learning.

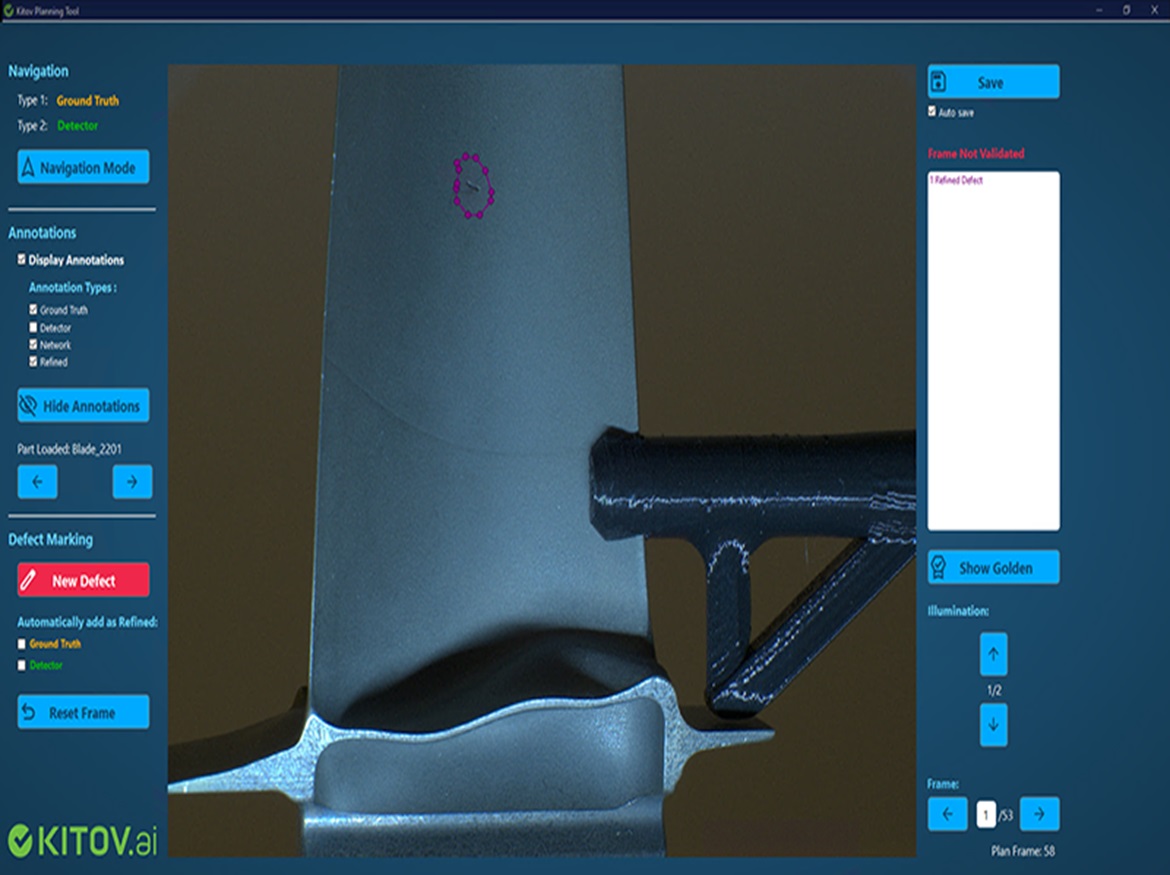

Enhancements in version 2.7 mainly shine in the Planner Tool, which integrates seamlessly with various robotic systems. It uses AI to create optimized inspection strategies and simplifies the process of transferring these plans to the inspection equipment. Improvements include a more accessible interface, equipped with intuitive icons, tool tips, contextual menus, and versatile features like an undo function for reversing unintended actions.

CAD2SCAN functionality, a vital part of the Smart Planner, benefits from refined workflows and additional improvements in the 2.7 update. It allows quality inspectors to define test parameters directly on a CAD model of the part being inspected, making it much easier and faster to handle components with complex shapes. The tool now supports an expanded range of quality tests that can be applied to a CAD model, enhancing its ability to detect missing components; mark part edges, patterns, and surfaces; and more.

Furthermore, the Workcell Configurator has been updated to allow for 70% quicker configuration and validation of robotic workcell hardware through a straightforward and intuitive user interface.

Dr. Rubner emphasized, “The launch of version 2.7 represents a significant leap forward, not just an incremental update. By making the interface more straightforward and enhancing the efficiency of workflows, we’re vastly improving the productivity and accuracy possible with AI-powered inspection in automated quality control processes.”