Loramendi S. Coop, headquartered in Vitoria, started its activity in 1973, and it’s part of the Mondragon Corporation since 2005. Loramendi’ s activity is focused on the design and supply of global foundry solutions: sand core manufacturing equipment, vertical molding machines, as well as providing spare parts and retrofit service. They maintain an alliance with Aurrenak S. Coop, through which they offer integral machine and tooling solutions.

Their main customers are global automotive manufacturers (OEMs and TIERs). BMW, Daimler, Volkswagen, Toyota, General Motors, Renault Nissan Group… and the main products they manufacture are cylinder heads and engine blocks, electrical housings, structural body parts, disc brakes, valves, and cores of different types.

In 2010, Loramendi started a project with a German OEM in which they have developed the inorganic process. That is a new green casting technology that reduces emissions and strengthens the cast components. As a result of this project, Loramendi has positioned advantageously above its competitors in terms of offering this type of solutions.

In 2016, they launched a new ambitious project related to the inorganic core manufacturing process, that consisted in the industrialization of the sand core’s additive manufacturing. This project has allowed Loramendi to develop worldwide, the first sand core production-line using additive manufacturing technology. In this project, the need for verification of the part’s geometry arises, requirement that in the traditional process is obtained in a relatively simple way. But, in this new process, it’s one of the points that cannot be stabilized so easily.

Unlike the traditional manufacturing (in which, as we only have a mold, only the wear or breakage of the mold causes defective), in this case there are many variables that affect the result. At this point, the domain of these variables and their influence isn’t total, so they contemplate the option that the complete line includes a final inspection cell.

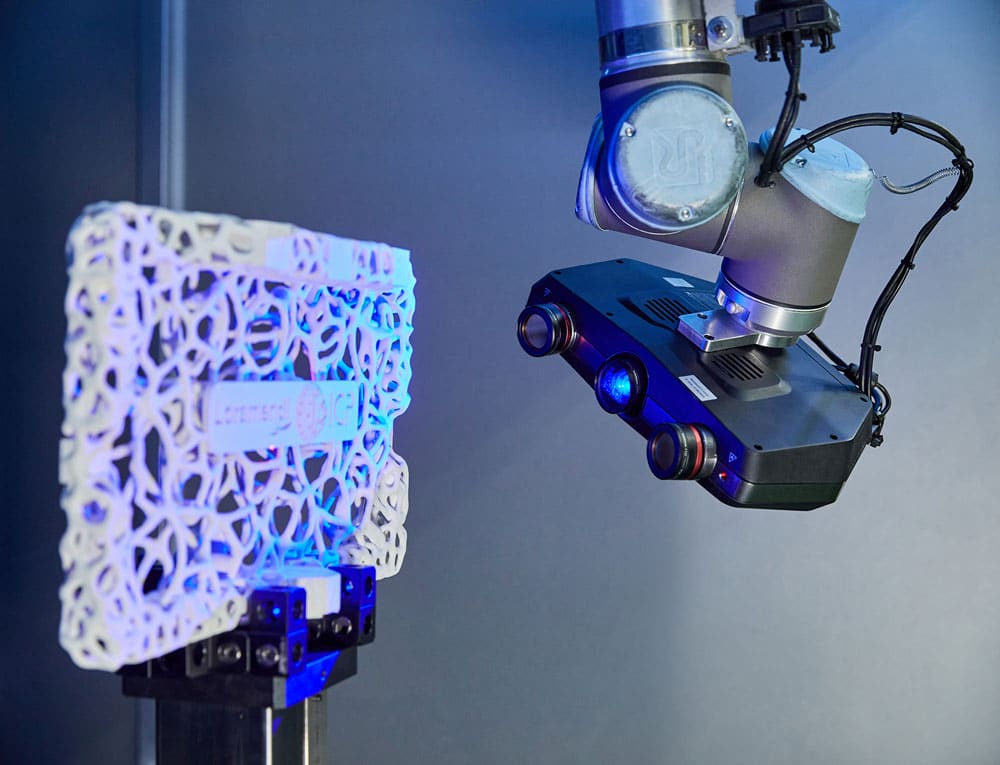

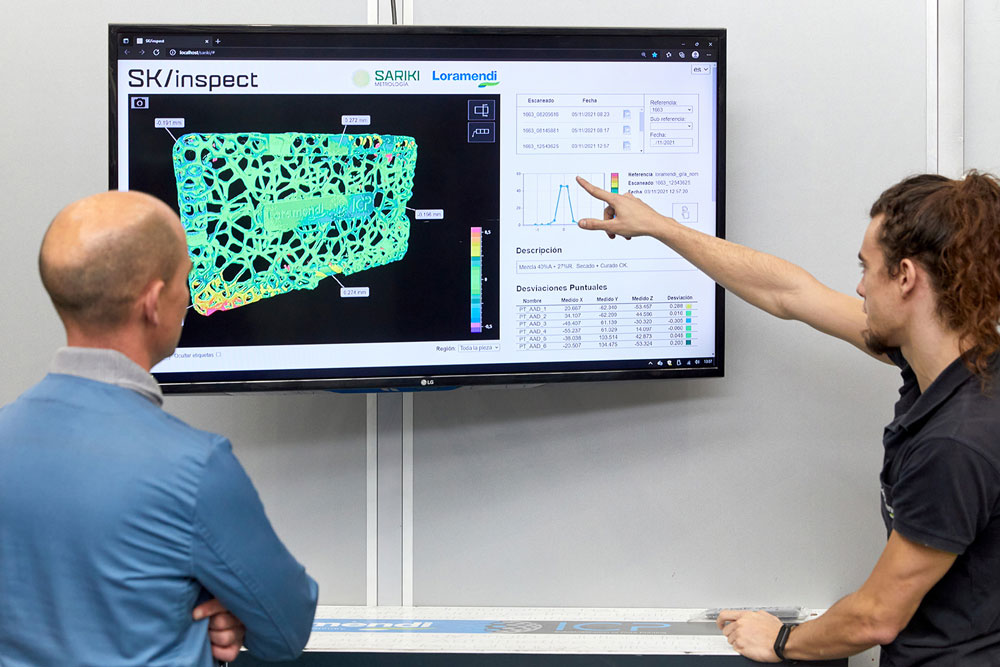

Sariki has collaborated with Loramendi in this project, by implementing the core inspection cell that uses structured light technology. SK/cell is a robotized inspection cell developed by Sariki, and it’s characterized by being automatic, flexible, and high speed. It’s capable of covering a wide range of part’s dimensions and geometries, and, nowadays, it’s used both for verification of additive manufacturing parts, and traditionally manufactured parts.

The structured light technology offers great versatility by allowing high-quality scanning of sand and resin materials. A validation process of the technology was carried out, involving many different parts regarding materials and geometries. SK/cell proved to be a complete solution for all the parts selected by Loramendi.

“We had analyzed many different alternatives, both from the technological and service point of view, and we finally opted for acquiring a technical solution developed in our geographic area, with the guarantee of a close technical support, experience and development capacity.”

Ales Olea

R&D technical project manager

The additive manufacturing process allows both reducing the number of parts and optimizing their geometry topologically. SK/cell is a suitable option for this kind of manufacturing process, due to its flexibility and capacity of massive data capture.

The part’s verification by the traditional methods, was previously performed by using conventional equipment and “go-no go” gauges. They also outsourced measurements on an ad hoc basis. The solution proposed by Sariki has allowed them to:

1) Optimize the part’s validation process.

2) Digitalize the inspection process.

3) Be more agile when detecting errors and process improvement proposals.

4) Having more information to analyze trends and process-failures in a more visual way.

5) Making the measurements reliable by working at high speed and within the cycle time, a critical parameter in this kind of facilities.

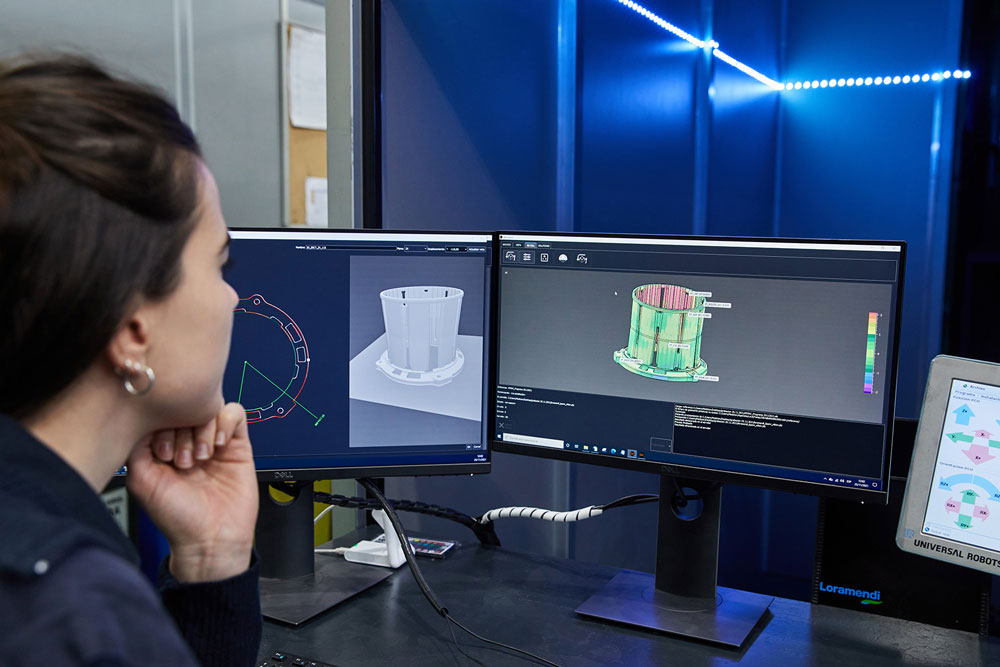

SK/cell is composed by a collaborative robot, a structured light scanner, and the SK/inspect software, that allows the cell’s integral management and the part’s complete inspection.

The structured light scanner is prepared to work in industrial environments. Its high capture speed, combined with the wide scanning volume, allows to significantly reduce the inspection time. It’s attached to the robot, which is suspended on a stand in a vertical position, in order to optimize the useful range of movement around the part.

SK/inspect is specifically developed to work in a CAD and “point-cloud” environment. Once the scanner captures the point-cloud from the sand-printed core, it performs the complete inspection of the part. The software includes a web platform where you can view the results from places outside the cell, and it includes algorithms that automatically perform both the scanner’s calibration and the adjustment between the scanner and robot coordinate systems.

We have performed validation tests with different technologies and manufacturers, and we finally identified that the structured light technology was the one that best fits our requirements. Sariki has a technological solution that works and guarantees us a close and agile technical support to meet our requirements as they arise.

Ales Olea

R&D technical project manager

The complete line is installed in Loramendi’ s facilities in Vitoria, and the responsible process-technicians have received the necessary training from Sariki to be able to work with the inspection cell. Ander Jimenez and Naroa Artaraz have been performing different tests (changes on different variables) during the validation process, and the analysis of its impact on the part’s final result is being verified with the SK/cell solution. This allows them to have all the information to identify if a part is within tolerance and, this way, validate whether the part is OK or NOT OK.

As future lines, Loramendi is considering the use the SK/cell inspection cell not only in core inspections, but also in other type of parts, even internally. What’s more, as mentioned before, the complete additive manufacturing lines require this type of inspections, and the company plans to include the SK/cell inspection cell in the lines that will supply to their automotive sector customers.