After the pandemic there has been a before and after in the development of the industry. A fact known to all, and from which we are recovering little by little. Therefore, it is time to update the machine park and improve production processes to be prepared for the economic reactivation.

At Innovalia Metrology we combine software and hardware with robotics and the most advanced technology in the field of dimensional measurement. In this way, we create and offer metrological solutions that allow us to achieve the highest productivity and efficiency in the production process for more than 30 years.

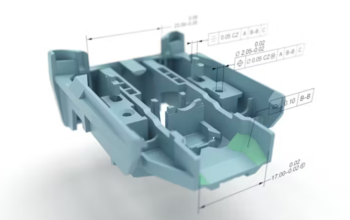

With M3 Hybrid we have managed to simplify the process of reading and measuring parts by combining two methods of capturing points – non-contact 3D scanner thanks to Optiscan and probing system – with M3 Software. This proposal already represents a 30% reduction in cycle time.

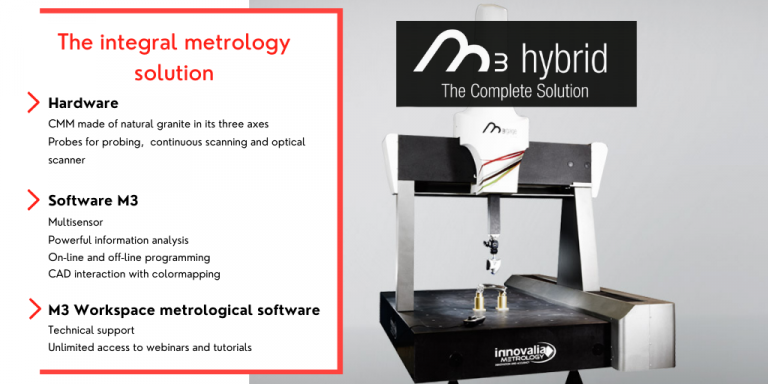

The comprehensive metrology solution, M3 Hybrid, is the result of years of experience and innovation and is comprised of a high-precision and accurate CMM, unique metrology software, and laser and contact sensorics providing the user with an accurate 3D part recreation. physics to measure.

M3, is the multisensor dimensional metrological software designed to work both in the plant and in the laboratory. Thanks to its ability to plot point clouds of more than 100 million, it allows measurements to be made quickly and accurately. It also offers all the metrological capabilities required for comprehensive quality control.

Another essential component of M3 Hybrid is Optiscan. A laser triangulation sensor with exceptional results on all types of materials and finishes. It offers great improvements in precision and in the optimization of the measurement time, which translates to a clear improvement in production times.

The three-dimensional measuring machines or CMM, which complement M3 Hybrid, are manufactured in natural granite in its three axes. In this way, they provide great dimensional stability and very precise movements, facilitating the collection of information in exact 3D.

M3 Hybrid surpasses in speed, precision and adaptability to the other market proposals. Its integration into production processes leads us to talk about intelligent manufacturing, zero defects and controlling the quality of any type of part at all times. A leap into the future that adjusts the quality process to companies.

If you want to know more about the integral metrology solution, click here.

Press contact:

Monika Góra

Evatronix SA

monika.gora@evatronix.com

phone: (+48) 33 499 59 36