Mapvision has just started testing a flexible welding cell. Here is how the solution functions and how it will make it possible for the manufacturing sector to be restructured.

How we enable flexible manufacturing and the smart factory

Being the eyes of smart factories is our objective at Mapvision. Robots now have eyes.

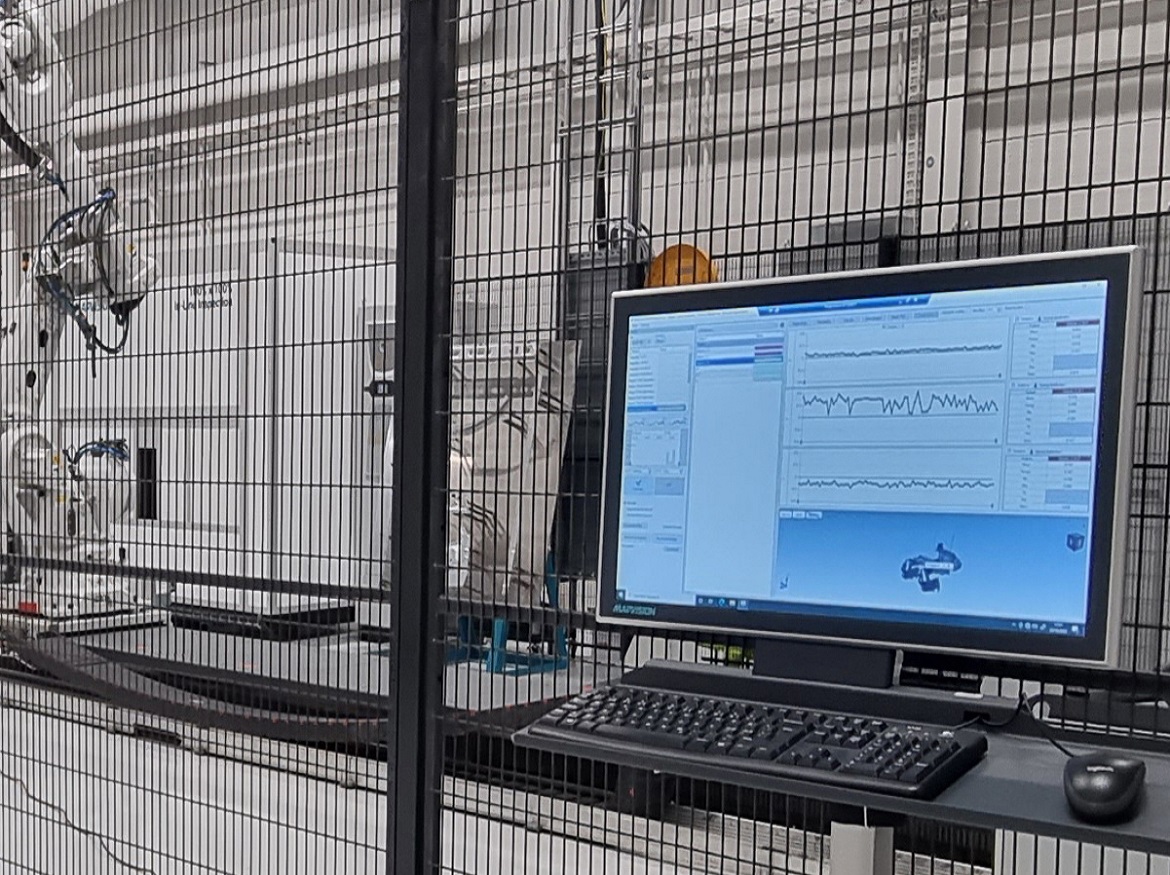

The flexible welding cell pilot that we recently started with Valmet Automotive is one recent step towards the aim (you may have seen the recent news about it).

In this post, we’ll go into more detail about how the Mapvision Smart Eye Cell solution functions and how it will actually help the manufacturing sector undergo reorganization.

How flexible should a flexible manufacturing cell be?

We must first talk about what flexible means before defining the manufacturing of the future.

Some welding cells have a shelf of fixtures from which a robot arm can select the appropriate fixture for various pieces. Although it is a step up from a single-purpose cell, the solution is still stiff and hardware-restricted, and any flexibility must be pre-planned.

There is little doubt that the fixture restricts flexibility. What about a welding cell without fixtures or jigs? Indeed, a welding cell without a fixture particular to a given item offers more freedom. How do we position the components so that welding may take place? then becomes the problem. The methods that we have seen thus far rely on pre-established physical holes for alignment grippers.

A system that uses a single coordinate system would have the most versatility. The robot arm may pick up any item with, for instance, suction cups or magnets when you can inspect the position of the part and give the robot immediate error correction instructions, and all robots in the production cell will know what the part is, where it is, and what to do with it. Only in a closed-loop system of this type does the cell truly relinquish reliance on its hardware.

Creating the all-new measurement-aided multi-purpose manufacturing cell

We at Mapvision are specialists in rapid, totally digital measurements and machine vision. a while back. We began to consider how we might apply that knowledge to develop a self-adjusting, multi-functional manufacturing cell that would free us from the constraints of conventional production lines.

Why not design a system that verifies the coordinates within the production cell and provides the gripping arms with the necessary prompt feedback and positioning instructions?

This served as the foundation for the project that we initially referred to as The Measurement-Aided Welding Cell.

An entirely different kind of Mapvision solution was necessary for the measurement-aided welding cell. We integrated our 100% x 100% in-line inspection solution’s cutting-edge multi-camera technology into a completely new hardware format that can serve as the flexible welding cell’s focal point.

In addition, we had to design interfaces for providing visual input to the manufacturing brain and test the communication veins that deliver immediate feedback for arm mistake correction. The cell needs to see, but the robots are blind, you see.

Fixtureless. Tick. Finished loop. Yes. It’s all here right now.

What we refer to as a flexible production cell is that. the Smart Eye Cell for Mapvision.

Mapvision Smart Eye Cell – enabling the factory of the future

Our proof-of-concept cell has now successfully completed the first pilots, and we are prepared for more.

A factory that can adapt to changes in production requirements and volumes can be created by replacing the outdated, rigid production lines with a network of these cells. This not only results in significant floor space savings. This is not just about precision positioning for robots either, we can generalize this machine vision concept to assist any production system that requires perfect shared coordinates.

You also receive immediate integrated quality inspection in the same cell (every cell!) following each process step, which helps to reduce waste.

In a world where production schedule adjustments are commonplace, that factory of the future delivers the highest level of capacity optimization. The promises of Industry 4.0 are realized in that factory.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.