Measure workpieces from 25 mm to 42.5 mm with a measuring range of ±100 µm and a repeatability of ≤0.1 µm.

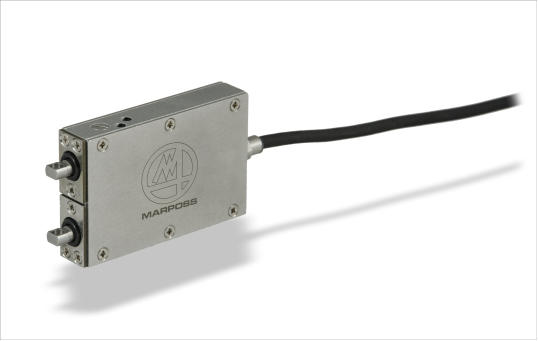

Marposs: Auburn Hills, MI) — Marposs, a world leader in measurement, inspection and test technologies, has announced Minimicromar3, an in- and post-process grinding gauge designed for small diameter measurement. This ultra-compact gauge is well-suited for the manufacturing of very small ground components such as fuel injectors, electronics and other parts.

The Minimicromar3 is designed for measuring external diameters, positioning and length for both smooth and interrupted surfaces. It can measure workpieces from 25 mm to 42.5 mm with a measuring range of ±100 µm and a repeatability of ≤0.1 µm. It is designed with a high degree of protection against coolant and abrasive substances. Its low thermal drift value (<0.1 µm/°C) helps maintain high measurement precision.

The Minimicromar3 can be used with a range of Marposs electronic units including the P7ME, P7UP, P7SYS, Blù and Blù LT for higher end applications and the P1dME and P3dME for entry to mid-level applications. The gauge, together with the associated electronic control unit, exchanges information and signals with the machine in order maximize performance and achieve the desired results. It is designed for quick and easy installation and operation.

For more information on Marposs gauging solutions for grinding, visit https://www.marposs.com/eng/family/grinders by calling toll-free 1-888-627-7677 or by E-mail to marposs@us.marposs.com. Follow our company activity at Facebook, LinkedIn or Twitter.

Marposs Minimicromar3 is well-suited for in- and post-process gauging of small ground components.