A successful machine tool manufacturer, StankoMachComplex was faced with a dilemma. As demand for its growing range of machine tools rapidly increased, the company’s rigorous product testing procedures were creating a bottleneck in production. It needed to accelerate testing throughput while increasing the accuracy of its precision measurements at the same time. A combination of Renishaw’s measurement solutions provided the answer.

Background

StankoMachComplex is a well-established manufacturer of a wide range of precision machine tools. It also provides a complete engineering support service, including CNC programming, repairs, and upgrades. Based in the City of Tver, 180 km northwest of Moscow, the company provides lathes and milling machines to customers in 45 states of the Russian Federation, Belarus, Estonia, and Ukraine.

Quality has been fundamental to the company’s ethos from its inception. Machine tools from StankoMachComplex conform to very stringent product specifications, Russian state standards, and international ISO 9000 quality standards.

Any machine tool leaving the Tver factory has been put through an intensive verification process, comprising zero load testing, load testing, and geometric accuracy testing. Product precision and repeatability are paramount.

Challenge

The commercial success of StankoMachComplex is borne out by the company’s production figures. In its first 20 years, it has produced more than 4,000 turning and milling machines. The impact of increasing demand heightened manufacturing volumes, and a rapidly expanding range of machine tool products, however, put increasing pressure on the company’s rigorous precision testing procedures.

In its early years, the company used manual testing methods and dial gauge indicators. Within a short time, it became clear that the approach was outdated. Testing was time-consuming, measurements were manually recorded, and human error was a concern.

Andrei Korobeynikov, Head of the Service Department at StankoMachComplex, said, “In the beginning, the process of measuring the positioning accuracy of just a single machine tool could take as long as 5-7 hours. Over time, this clearly had an adverse effect on our productivity. To guarantee the quality and accuracy of our machine tools, we had to find more modern, higher-precision measuring equipment that would help us increase testing throughput.”

Reflecting on the company’s variety of machine tool products, the equipment would need to be capable of measuring a complete range of parameters, including the geometry of frames and guides, CNC positioning, linear and rotary axes.

Renishaw measuring systems guarantee the quality and reliability of our company’s products. The main advantages are the ease of use, high precision, and measurement efficiency, enabling us to have 100% confidence in our products.

StankoMachComplex (Russia)

Solution

“The ISO 9000 series of quality standards require that manufacturing and inspection equipment is calibrated, monitored and inspected using recognized and traceable systems and procedures,” stated Andrei Korobeynikov.

He added, “Faced with acquiring new measurement systems for the Tver machine tool plant, we began with some in-depth market research. What we soon determined was that the leading international machine tool manufacturers were using Renishaw calibration solutions. Evidently, a tried and tested solution, was to lead to a step-change in testing procedures at StankoMachComplex and we have been reassured every day that we made the right decision.” said Andrei Korobeynikov.

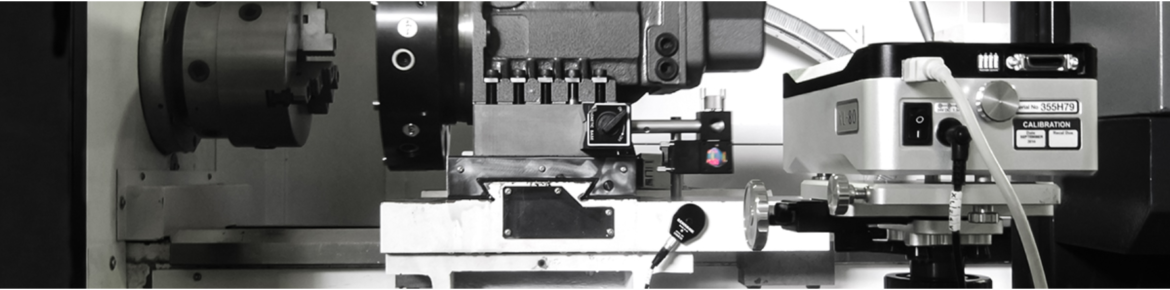

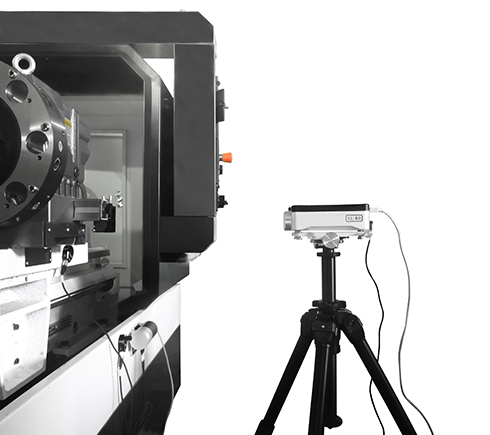

The first stage in the collaboration between StankoMachComplex and Renishaw was the acquisition of the QC20-W ballbar and the XL-80 laser system. The XL-80 system is used to check the accuracy of movement in machine tools. Testing is carried out on each axis individually and, combined with the QC20-W data, gives a full picture of the condition of the machine tool. Where possible, compensation can be applied to further performance.

After starting the production of mill-turn machines with rotary axes, StankoMachComplex purchased an XR20-W rotary axis calibrator which can measure rotary axes up to ± 1 arc second. The system provides high integrity, non-contact reference measurement, remote from the axis under test. The XR20-W has the flexibility to be mounted on or off the center of the machine’s rotary axis using Renishaw’s Off axis rotary software.

Results

Today, StankoMachComplex’s tool kit includes five Renishaw measurement systems: two XL-80 laser interferometers, two QC20-W ballbars, and an XR20-W rotary axis calibrator.

Andrei Korobeynikov said, “We use the Renishaw measurement systems daily. A thorough inspection and testing of the precision of machine equipment allows us to confirm the class of the machine tool and guarantee the high quality of its operation. The main advantages of the Renishaw measuring systems are their ease of use, high precision, and measurement efficiency. In comparison with manual testing measurements, the process of measuring the positioning precision has been reduced by a factor of 15, from 5-7 hours to 15-30 minutes.”

“Further advantages of working with Renishaw include regular software updates with the aim of eliminating errors, expanding functionality, updates to analysis standards, and comprehensive technical support,” he added.

Andrei Korobeynikov concluded, “Renishaw measuring systems have enabled us to be 100% confident in our products. The measurement systems store the results of all tests conducted, confirming machine tool compliance with the declared precision class. And if needed, we can also use the equipment to verify machine tool performance at a customer’s site. Working with Renishaw measuring systems guarantees the quality and reliability of our company’s products.”

To know more, please check Renishaw.