Direct measurement has become the gold standard for precise cavity pressure measurement in injection molding, where the tiniest deviation from the standard can lead to subpar product quality and even unsafe products. Especially highly regulated industries such as medtech benefit from monitoring product quality to sort out faulty parts automatically and eventually optimize processes. However, direct cavity pressure sensors come into immediate contact with the melt in the cavity, which can have a negative impact on the longevity of the sensors or even damage them. Measurement specialist Kistler has put a new solution on the market which avoids this problem in injection molding: contact-free measurement. Here, piezoelectric sensors measure the strain that the injected melt puts on the mold’s walls instead of the pressure in the cavity, thus avoiding contact with the melt. This technology generates precise and reproducible values and is especially suitable for the quality assurance of grade A surfaces, medical parts such as lenses or materials with a low viscosity such as liquid silicone.

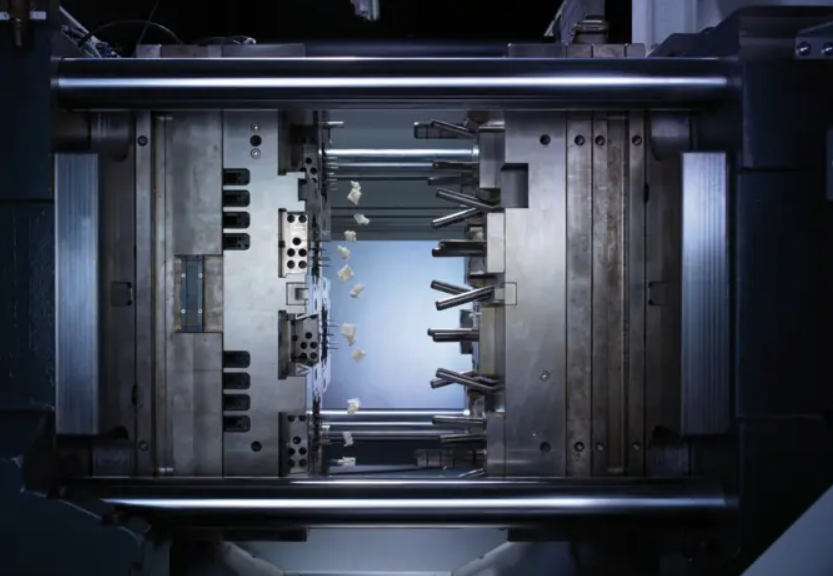

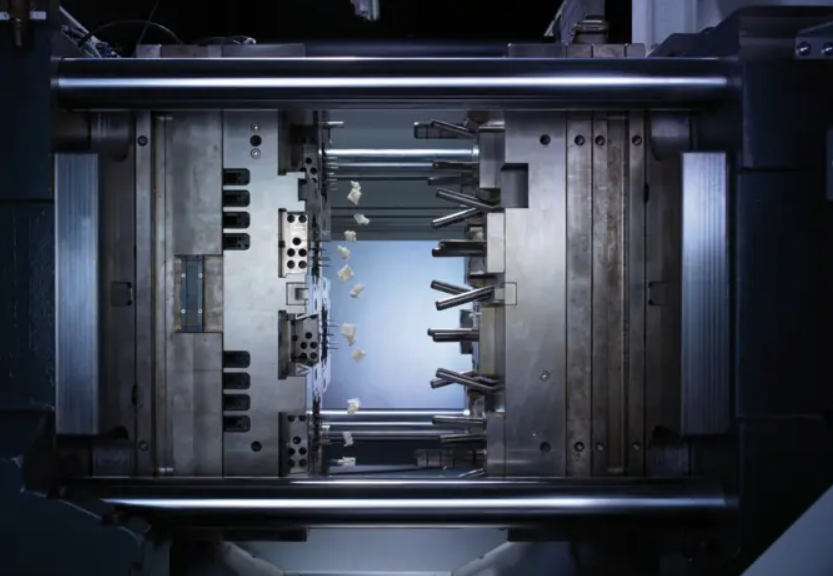

Using advanced cavity pressure sensors and matching software allows injection molders to measure cavity pressure during the entire production process. By taking an ideal product, they can use the measuring curve from its production as a quality benchmark that all future processes are measured against. In addition, injection molders can optimize their production processes based on the deviations from the targeted measuring curve. When direct measurement is involved, sensors and cables are installed directly into the mold’s wall (see figure 1). The sensor’s tip is level with the wall so that the injected plastic melt comes into direct contact with the sensor. The sensor can then measure absolute cavity pressure values and compare them to the ideal curve. While this technology is as yet unmatched in terms of accuracy, it does come with some disadvantages: for example, the sensor leaves a small mark on every manufactured plastic part. While this mark is minimal, in particular when using miniature sensors, this can still be an issue for high-precision products such as lenses. Also, the direct contact of the cavity pressure sensor with the plastic melt when measuring cavity pressure directly, makes it susceptible to pollution. As a result, the status of the sensor needs to be closely monitored and may require frequent maintenance and replacement, especially with the use of certain materials.

Aside from direct measurement, some medtech companies also use indirect sensors to measure cavity pressure in injection molding. Unlike direct sensors, they can be retrofitted to the mold, as they are positioned behind the ejector pins (see figure 2). However, this also makes them vulnerable to errors, for instance if the mounting hole isn’t a perfect fit either too small or too large for the ejector pin. They can also be impacted by the gases emitted by the plastic melt. Melts with low viscosity such as liquid silicone can even flow into the ejector pin hole.

Contactless cavity pressure sensors: a reliable alternative to direct and indirect technologies in injection molding

With these methods in mind, Kistler started to work on a measuring alternative that would provide precise and reproducible measurement but avoid disadvantages such as a negative impact on the sensors during the injection molding process. The development team came across a procedure which completely avoids melt contact with the cavity pressure sensors as it measures the strain that the pressure of the melt puts onto the mold’s metal walls. The most remarkable feature: although this contact-free measurement method does not measure absolute cavity pressure values, it allows injection molders to draw accurate conclusions about them. Measuring the strain results in a very similar measuring curve to other measurement methods. Even more importantly: measuring strain leads to reproducible curves, thus meeting an essential requirement of quality assurance and regulatory guidelines.

The major advantage of contact-free cavity pressure measurement as opposed to direct measurement technology lies in its positioning: since the sensors do not have to be in direct contact with the plastic melt, they can be placed two to four millimeters behind the cavity wall (see figure 3). They consequently leave no imprint on the manufactured product, making the technology first choice for the production of grade A surfaces or high-precision products such as lenses, where even the smallest imprint can impact the product’s quality. Positioned behind the wall, these special cavity pressure sensors, or miniature longitudinal measuring pins, are protected from the plastic melt and additional influences such as gases or even outside dirt. This reduces maintenance efforts to a minimum. The sensors can be removed easily for service purposes. They are also easy to install with more potential spots available in the mold: They can be positioned independently of the demolding direction and do not need space close to the cavity. They only require one mounting hole where the sensor is placed and set with a predefined preload.

Finding the perfect placement of cavity pressure sensors with a finite element analysis

Additionally, Kistler supports customers in finding the perfect spot by providing a finite element analysis (FEA). This helps customers find a suitable spot for their sensors and evaluate at which maximum distance to the mold wall the sensor can be placed while still providing accurate measurements. For the FEA, customers send in a 3D CAD model showing where they want to place the sensor. The Kistler team then calculates what the actual sensitivity of the cavity pressure sensor in that position will be via finite element analysis (see figure 4), factoring in both the strain on the metal and side forces. Their report then shows if the chosen position will allow the sensor to accurately measure the cavity pressure or suggest alternative placements, if that is not the case.

Miniature sensor (longitudinal measuring pin) for injection molding applications in medtech

Kistler sensors have already been used to measure strain in other applications, such as machining, where strain sensors are used to measure dynamic or quasistatic forces on fixed or moving machine parts. When developing the first strain sensor for injection molding, Type 9247A, Kistler was thus able to leverage its experiences with these applications as well as its comprehensive knowledge on measuring cavity pressure. With a circumference of 4.4 millimeters, the 9247A sensor is suitable for the manufacturing of larger plastic parts and has been used in injection molding both in the cosmetic and in the automotive industry since 2010. Focusing on applications in medtech in particular, Kistler then looked at developing an even smaller sensor suitable for the compact molds used for products such as lenses, syringes and EpiPens.

As a result, Kistler launched the first-ever version of a piezoelectric miniature longitudinal measuring pin in 2018 and an updated version, the 9239B miniature longitudinal pin, in the fall of 2022. With a circumference of only 2.5 millimeters, this modified cavity pressure sensor can be used in small molds or ones that have limited space. One significant difference between the two sensor versions is the crystal: while the previous version of the sensor used a quartz crystal, the new version now features a PiezoStar crystal specifically grown by Kistler. This update raises the sensor’s sensitivity from 5.9 picocoulomb per Newton (pC/N) to 27 picocoulomb per Newton (pC/N). This allows the sensor to measure weaker signals reliably and precisely.

Quality assurance: the road ahead for contact-free cavity pressure measurement in injection molding

Contact-free cavity pressure measurement utilizing longitudinal piezoelectric sensors offers three main advantages, namely not leaving a mark in the surfaces of manufactured products, precise measurement and low maintenance. This is great news for quality assurance in the medtech industry, where manufacturing companies need highly reliable cavity measurement and process monitoring systems in injection molding – not only to produce high-quality products but also to comply with regulatory requirements for quality assurance such as the GMP in the U.S. and MDR standards in Europe. Within complex medical device production, both direct and contact-free cavity pressure measurement can fulfill different demands. For instance, manufacturers can use contact-free cavity pressure sensors for high-precision products and instances where molding a perfect surface is essential, while still relying on direct measurement technology in cases where small marks left on the product don’t impact its quality.