A Key Automotive Industry Player reduces it Inspection Time by 7 thanks to Metrolog X4.

Metrologic Group specialized in integrated 3D measurement software solutions, universal and compatible with all measurement technologies on the market, and a major European player in the automotive industry – have carried out a joint project to automate and standardize a multi-robot measurement system, connected to the manufacturing line.

This joint project has been validated by the manufacturer on its assembly lines. By utilizing Metrologic Group’s software solutions, it has been able to optimize its industrial/supply chain workflow while dividing by 7 the times of controls and restitutions to the manufacture.

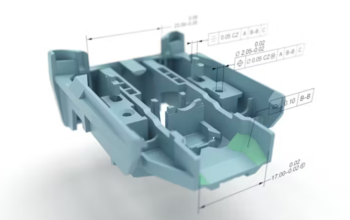

All the measurement capabilities of conventional machines with contact probing systems (CMM) in laboratories, have been transferred to robotic technology solutions, connected to the line and equipped on this cell with a radar laser, thus allowing a non-contact laser measurement.

The strength of this solution is having the 3D measurement process transferred from the laboratory environment directly to the assembly line.

The control of this system is carried out in “by-pass” mode, perfectly integrated into the production line with the vehicle assembly process. This solution allows to maintain the availability of the assembly line, control all critical characteristics and provide the same quality of measurements as a three-dimensional machine.

The performance of measurement accuracy and applications driven by the Metrolog X4 i-Robot software in this automated environment have been approved by the manufacturer.

The whole device is driven by a unique software solution: Metrolog X4 i-Robot.

The requirements of this renowned automotive group fit perfectly with the Metrologic Group’s i-Robot software workflow.

The solution connects directly into the assembly line and provides complete automation. A range of specific applications has been developed to better understand the industrial constraints:

- Robots trajectories optimization according to the measurement to acheive specifications systems;

- The management of data acquistions to calculate and analyse dimensional entities;

- Automatic generation of an optimized inspection range with robot trajectories and extraction strategies (associated with Silma X4 i-Robot);

- Integration of manufacturer specific measurement and inspection rules in Metrolog X4 i-Robot.

In a context of industrial digitalization, this project, co-piloted by Metrologic Group’s Design Office and its Robotic Projects Team, allows this automotive group to meet a dual objective: guaranteeing the quality of vehicles and the competitiveness of its industrial system (+ better position themselves as a world class automotive manufacturer?).

Metrologic Group capitalizes on more than 40 years of 3D metrology expertise, including 10 years in robotic measurement, in the most demanding industrial environments, to offer a range of flexible solutions, X4 i-Robot, which meets the future industry challenges.

Metrologic Group is a partner of industries on the way to 4.0.

Metrologic Group is proudly paving the way forward into industry 4.0.

Metrologic Group provides cutting-edge and robust 3D measurement software solutions, whose innovation and adaptability ensure its automotive and industrial customers and partners to benefit from the highest quality standards on a daily basis.