The OEM and aftermarket automobile industries are served by Livernois Motorsports & Engineering, based in Dearborn Heights, Michigan, with engineering services, performance goods, and specialized vehicle design and manufacturing. Livernois blends conventional experience and knowledge with cutting-edge measurement solutions from Verisurf Software, Anaheim, CA, throughout the process of supplying custom-produced performance parts, service, and tuning to maximize the performance, form, and fit of every build.

Today, a wide range of vehicles, including dragsters, off-road buggies, trucks, and more, can use high-performance engines and engine components, including modified OEM designs, retrofit street mods, and road racers. One thing is certain: high precision and high performance go hand in hand. The approach to higher engine performance varies based on the builder, budget, and expectations for the finished product. Everyone is looking for greater power, typically from an existing platform, including OEMs, performance shops, racing teams, and do-it-yourselfers.

Livernois is in the business of improving performance in street-legal cars by boosting fuel and airflow without sacrificing toughness. This highlights the importance of precision in their designs, manufacturing, and testing to maintain EPA compliance. Products and services offered by Livernois Performance Engines include full-service machining for cylinders, heads, and blocks, block tear-down, and assembly, full engine modifications and re-builds, new engine design/builds, custom porting and CNC machining to finish parts, cylinder accessories, engine accessories, and performance component packages for stock engine brands.

With many of our modifications coming straight from the factory, Livernois specializes in late-model Ford, GM, and Chrysler performance parts. We are located in Dearborn, the center of American auto manufacture, in part because of this, according to Livernois President and CEO Dan Millen.

Advances in metrology are being used by performance engine designers and builders, like Livernois Motorsports, to boost horsepower, enhance component designs, and ensure that everything fits together. For a customizable measurement solution to satisfy their diverse demands, Livernois worked closely with Verisurf dealer RMC Engine Rebuilding, Inc., Saginaw, MI. For engine builders to reverse-engineer as-built components, Verisurf software is a multi-functional, purpose-built measurement platform. The software uses Model Based Definition (MBD) to generate intelligent CAD models that act as the standard for final part design, manufacture, and quality assurance. The measurement solution is also used to determine the amount of space needed and to assist in designing fixtures like mounting brackets.

When launched, Verisurf can be found on the Mastercam ribbon toolbar menu because it is developed on the Mastercam platform. All other well-known CAD programs can be used with Verisurf CMM software, which also operates all fixed and portable CMM hardware.

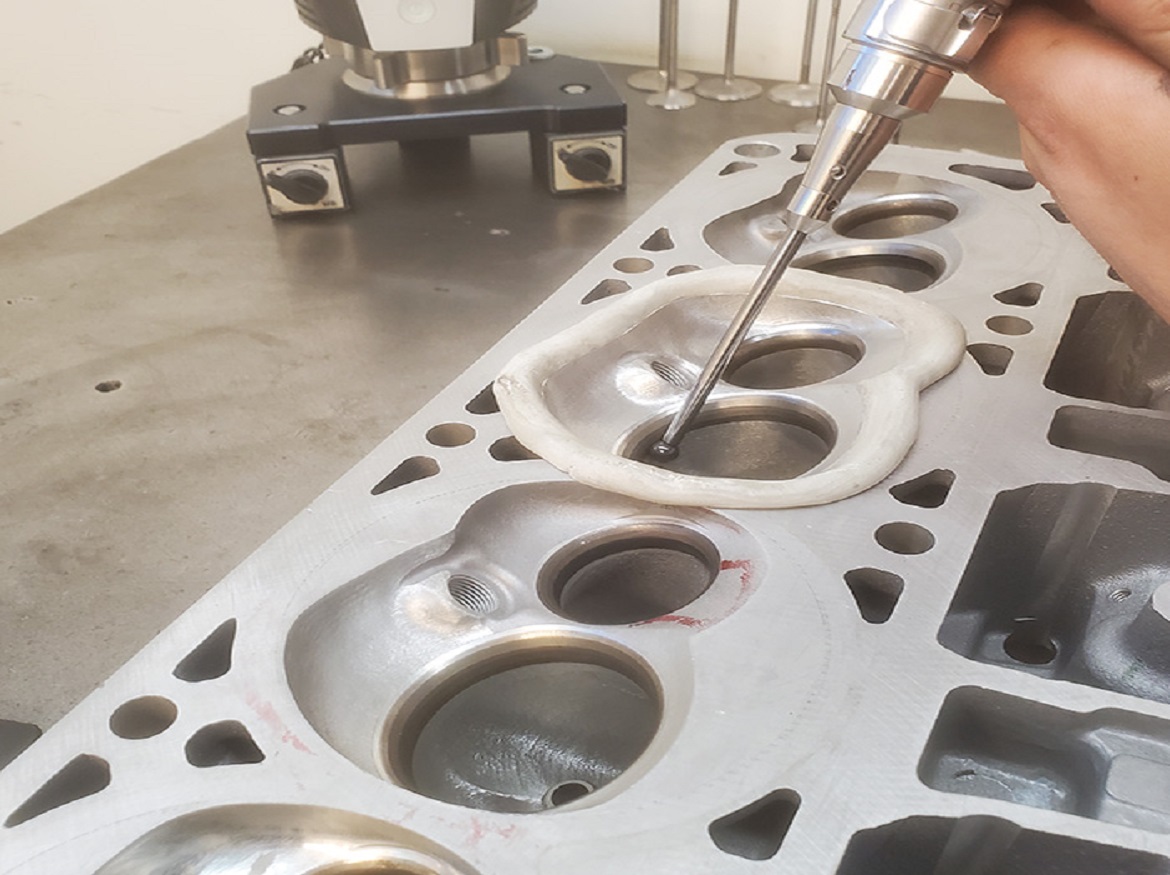

“To operate a Hexagon Absolute Arm with an RS-6 scanner attachment and capture measurement points, we chose Verisurf software. In probe mode, the CMM may record individual measurements; in scanner mode, it can record a complicated surface area. Depending on the project at hand, the measurement data is saved immediately to the software for analysis and processing, according to Grant Rathwell, CAD/CAM and Machine Operator at Livernois. We see the entire system as a versatile and effective measurement instrument, and we constantly come up with new applications for it.

3D CAD

A 3D CAD model using Model-Based Definition holds the key to the repeatable performance of a certain design component (MBD). When MBD is used, the 3D CAD model has all the specific details required to create and replicate a part. This covers every aspect, from product design and manufacturing to quality control. The 3D CAD model serves as the final design authority and contains all the information needed to duplicate the item through inspection. In essence, a simulated golden component. It’s great if you’re fortunate enough to start your project with a precise 3D model, but that’s uncommon, especially when it comes to mods.

Reverse Engineering

“When you don’t already have MBD data, you have to produce it. One excellent example is tuning, which accounts for around 75% of the reverse engineering work done at Livernois, according to Rathwell. The performance of the cylinder surface, combustion chamber, intake, and exhaust runners, supercharger, and turbocharger inlets, as well as the intake and exhaust flanges and valves, must all be maximized. Some castings are worse than others, and they are not all ideal. The ability to spot problems and improve flow can have a significant impact on performance. Unshrouding the valve while remaining inside the fire ring, checking chamber clearances, checking runners to the short turn to the bowl, cleaning up the areas where it meets the seat, smoothing out valve seats, and adjusting seat angles are a few of the things we look at when tuning to improve performance. To determine whether the tool should enter from the runner side or the bowl side, reverse engineering is useful, according to Rathwell.

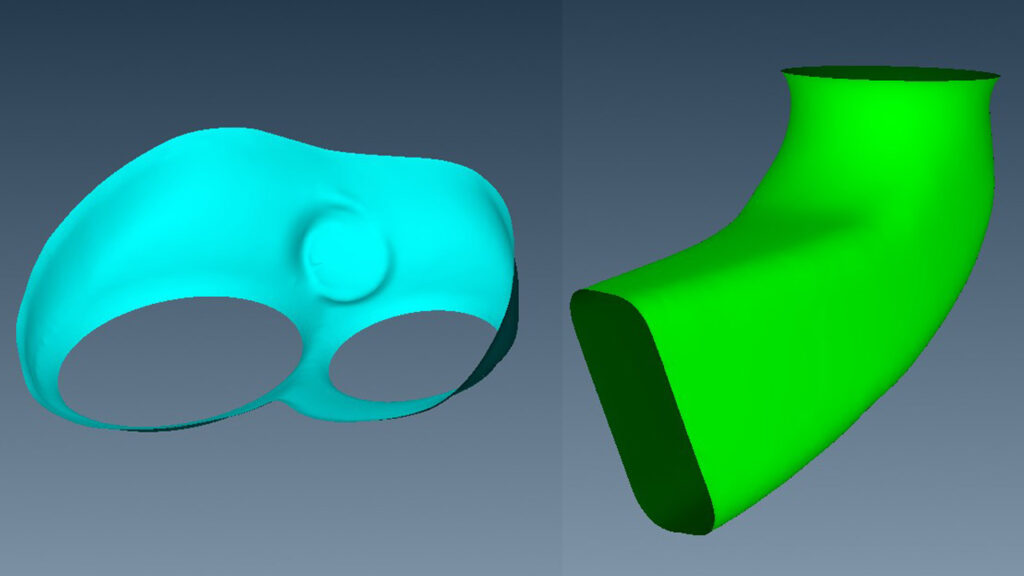

When Livernois needs to quickly convert as-built artifacts into CAD models for design modification, they use the Verisurf Performance Engine Builder Suite, which comprises the CAD, Measure, Reverse, and Fast Surface modules. For our standard porting applications, we jump right into Quick Surface for design after moving from a scan to a point cloud to a mesh. The surfaces are of good quality, and the file does not bog down when we need to export it. Our port design time has also been cut overall by 75%, according to Rathwell. Rathwell continued, “Using Verisurf, we can teach technicians with little to no CAD expertise how to reverse engineer.” Port designers may quickly alter complex surface geometry and produce high-speed toolpaths for machining with the Verisurf Quick Surface program. Livernois handles all aspects of tuning in-house, including reverse engineering, design, and manufacturing.

Making it Fit

Making everything fit under the bonnet is frequently the hardest issue when making engine modifications. Livernois measures, designs, and constructs pulley brackets, accessory brackets, and bespoke valve covers, and even does best-fit analyses for turbo inlets using Verisurf software. “You never know what you’re going to run across; sometimes we have to convert a hole into a bracket or make a clean installation for a fuel pump assembly that has been modified. We can only accomplish what we need to because of the measurement software’s versatility, according to Millen.

“We take great satisfaction in providing the greatest customer service, premium automobile performance items, and related accessories, all at competitive pricing. This would be a hard promise to keep without innovation and the use of technology, according to Millen. Livernois can install everything they offer at its 36,000-square-foot facility in Dearborn in addition to its retail showroom and online store. In addition to fifteen vehicle hoists, all-wheel drive, and portable 2-wheel drive chassis dynamometers, engine dynamometers, a full engine machine shop, an engine build department, a department for manufacturing private label and custom products, a center for cylinder head development, flow benches (600/1020), CNC machining centers, and a full fabrication shop are all included in the manufacturing and service facility.

Port Tuning Workflow

This example involves measuring a combustion chamber for reverse engineering. Design improvements will be made to the as-built 3D CAD model to boost fuel-air flow and horsepower. Due to the complicated surface profile and numerous dynamic transitions of the chamber, non-contact laser scanning is being used. Around the chamber where it joins the deck, modeling clay is positioned. In order to reduce clean-up and preserve a sharp edge that is square with the deck, this is done to help with the post-scan design.

Once more, probing is utilized to record internal geometry from the port’s open side. The ability to reach deep inside the port and measure its full interior profile is made possible by a variety of probe lengths.

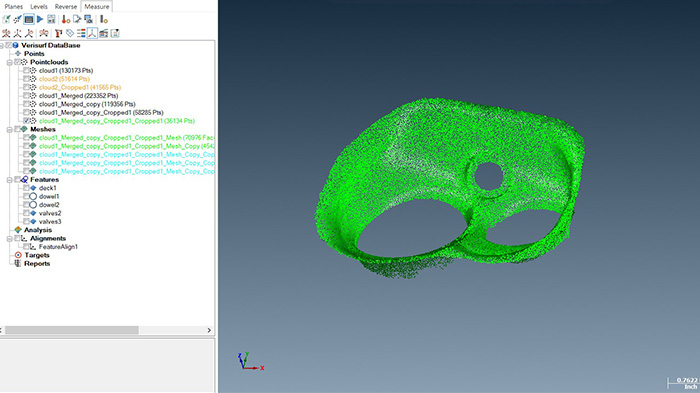

Verisurf Software gathers both non-contact scan data and contact probe data, which are then presented as point clouds available for reworking and conversion to mesh models.

Tools from Verisurf Software can quickly clear up any over-scan data as well as any other incorrect data. The point cloud is then transformed by the software into a watertight mesh with smooth geometry that can be used to examine the flowlines of all features.

Credits: Verisurf

Click on the following link, Metrologically Speaking to read more such news about the Metrology Industry.