- 3D Inspection in Metrology 3D Scanning

Introduction to 3D Inspection in Metrology In today’s fast-evolving industrial landscape, the quest for precision and efficiency has never been greater. At the heart of this pursuit lies metrology, the science of measurement, which ensures that every component lives up to its predefined standards. With the advent of 3d inspection scanners, metrology has experienced a transformative

Introduction to 3D Inspection in Metrology In today’s fast-evolving industrial landscape, the quest for precision and efficiency has never been greater. At the heart of this pursuit lies metrology, the science of measurement, which ensures that every component lives up to its predefined standards. With the advent of 3d inspection scanners, metrology has experienced a transformative - Enhancing Quality Assurance and Quality Control with 3D Scanning

In modern manufacturing, precision and efficiency in quality assurance (QA) and quality control (QC) are crucial for maintaining high standards. Traditional inspection methods can be time-consuming and prone to errors, making it essential for industries to adopt advanced measurement solutions. 3D scanning for quality control and quality assurance has emerged as a critical technology for improving inspection

In modern manufacturing, precision and efficiency in quality assurance (QA) and quality control (QC) are crucial for maintaining high standards. Traditional inspection methods can be time-consuming and prone to errors, making it essential for industries to adopt advanced measurement solutions. 3D scanning for quality control and quality assurance has emerged as a critical technology for improving inspection - Automated quality: A new era of possibility

Manufacturing can be a tough industry, operationally, financially and physically. There are many solutions out there that promise to alleviate these challenges, but few realistically claim to service each of these areas as comprehensively as automation. In this blog, we’ll explore the power of automated quality for consistent and reliable results across the board. While

Manufacturing can be a tough industry, operationally, financially and physically. There are many solutions out there that promise to alleviate these challenges, but few realistically claim to service each of these areas as comprehensively as automation. In this blog, we’ll explore the power of automated quality for consistent and reliable results across the board. While - Fermi’s Paradox and The Silence of Data in Manufacturing

“Where is everybody?” That was the question Enrico Fermi asked over lunch in Los Alamos, 1950. Fermi, a renowned physicist, was referring to the “maddening silence” of space, given the apparent likelihood of life existing elsewhere in the universe – a concept now known as Fermi’s Paradox. In this blog, we look at the parallels between Fermi’s

“Where is everybody?” That was the question Enrico Fermi asked over lunch in Los Alamos, 1950. Fermi, a renowned physicist, was referring to the “maddening silence” of space, given the apparent likelihood of life existing elsewhere in the universe – a concept now known as Fermi’s Paradox. In this blog, we look at the parallels between Fermi’s - What Is an OBJ File and How to Use It?

In the field of 3D graphic design, the OBJ file format is one of the most essential formats, particularly well-suited as a universal exchange format for non-animated 3D models. Its simplicity and robust data storage capabilities make it highly regarded in 3D modeling, architectural rendering, and virtual reality applications. Before diving deeper, let’s explore the

In the field of 3D graphic design, the OBJ file format is one of the most essential formats, particularly well-suited as a universal exchange format for non-animated 3D models. Its simplicity and robust data storage capabilities make it highly regarded in 3D modeling, architectural rendering, and virtual reality applications. Before diving deeper, let’s explore the - Intelligent Model Based GD&T for Inspection

A PRACTICAL FIRST STEP TOWARD COMPREHENSIVE MODEL-BASED DEFINITION The central concept embodied in model-based definition (MBD) is that the 3D CAD model provides the detailed product information necessary for all aspects of the product definition. Engineers have wanted to harness the power of MDB for years. A true implementation of MBD is much broader than

A PRACTICAL FIRST STEP TOWARD COMPREHENSIVE MODEL-BASED DEFINITION The central concept embodied in model-based definition (MBD) is that the 3D CAD model provides the detailed product information necessary for all aspects of the product definition. Engineers have wanted to harness the power of MDB for years. A true implementation of MBD is much broader than - Revolutionizing 3D Scanning with Built-in Photogrammetry: Precision, Efficiency, and Innovation

Photogrammetry, first introduced as a concept by German architect Albrecht Meydenbauer in 1867, has become a game-changer in the field of 3D scanning, offering a cost-effective and versatile method for capturing the physical world in digital form. By using multiple photographs taken from different angles, photogrammetry 3D scanning allows for the creation of highly detailed, accurate 3D

Photogrammetry, first introduced as a concept by German architect Albrecht Meydenbauer in 1867, has become a game-changer in the field of 3D scanning, offering a cost-effective and versatile method for capturing the physical world in digital form. By using multiple photographs taken from different angles, photogrammetry 3D scanning allows for the creation of highly detailed, accurate 3D - Embrace Model Based Definition

Increasing numbers of aerospace manufacturers are benefiting from model-based definition’s quality assurance processes. MBD for CAD/CAM The path toward the paperless airplane began years ago. Computer-aided design (CAD) was a significant step in that direction. Next, computer-aided manufacturing (CAM) allowed use of the CAD model for programming a digitally controlled device, applied most notably to

Increasing numbers of aerospace manufacturers are benefiting from model-based definition’s quality assurance processes. MBD for CAD/CAM The path toward the paperless airplane began years ago. Computer-aided design (CAD) was a significant step in that direction. Next, computer-aided manufacturing (CAM) allowed use of the CAD model for programming a digitally controlled device, applied most notably to - How Can 3D Laser Scanner Accelerate Automotive Film Paint Design?

Looking for a new way to improve your daily workflow of automotive customization? See how Scantech’s cutting-edge 3D scanning solutions can improve the automotive film paint design in this cast study. The client is a leading company in the industrial design and 3D printing sectors in China, with a strong presence in the automotive film industry. Their

Looking for a new way to improve your daily workflow of automotive customization? See how Scantech’s cutting-edge 3D scanning solutions can improve the automotive film paint design in this cast study. The client is a leading company in the industrial design and 3D printing sectors in China, with a strong presence in the automotive film industry. Their - How to Perform Dimensional Inspection of Pressure Vessels Using 3D Scanning

Pressure vessels are essential components in industries like oil and gas, chemical manufacturing, and energy production. Their primary function is to safely contain fluids or gases under high pressure or vacuum, making their integrity critical to operational safety. The sudden release of energy from a pressure vessel can cause catastrophic damage, which may endanger lives.

Pressure vessels are essential components in industries like oil and gas, chemical manufacturing, and energy production. Their primary function is to safely contain fluids or gases under high pressure or vacuum, making their integrity critical to operational safety. The sudden release of energy from a pressure vessel can cause catastrophic damage, which may endanger lives. - 3D Scanner Inspects Mining Milling Drum in Under 5 Minutes

Mining machinery are essential for efficient and effective extraction of minerals and materials. Among the critical components of this machinery is the milling drum. These specialized tools are designed to handle some of the most challenging tasks in mining, including the fragmentation of hard rock and the preparation of materials for further processing. The Mining

Mining machinery are essential for efficient and effective extraction of minerals and materials. Among the critical components of this machinery is the milling drum. These specialized tools are designed to handle some of the most challenging tasks in mining, including the fragmentation of hard rock and the preparation of materials for further processing. The Mining - How 3D Scanning Help in Architectural Preservation

After more than five years of intensive reconstruction, Notre-Dame Cathedral has finally revealed its new self to the world. The historic Parisian landmark, which dates back over 800 years, suffered devastating damage in a fire that broke out in 2019. Within just one hour, the flames ravaged much of the cathedral’s structure, threatening to erase centuries

After more than five years of intensive reconstruction, Notre-Dame Cathedral has finally revealed its new self to the world. The historic Parisian landmark, which dates back over 800 years, suffered devastating damage in a fire that broke out in 2019. Within just one hour, the flames ravaged much of the cathedral’s structure, threatening to erase centuries - The cost dynamics of digital prototyping in the automotive industry

Taking a zero prototyping approach to automotive manufacturing can result in huge benefits for an organisation. By using simulations to reduce the need for physical prototypes in the early stages of the development cycle, manufacturers can affect cost in all areas of the business. Cost is not only a fiscal concept— it may be represented

Taking a zero prototyping approach to automotive manufacturing can result in huge benefits for an organisation. By using simulations to reduce the need for physical prototypes in the early stages of the development cycle, manufacturers can affect cost in all areas of the business. Cost is not only a fiscal concept— it may be represented - A Practical Approach to Advanced Manufacturing Education at Van Buren Tech

Van Buren Tech (VB TECH), Lawrence, Michigan, is an innovative Career and Technical Education (CTE) institution. As an affiliate of the Van Buren Intermediate School District, VB TECH offers a practical approach to education, instilling in 11th-12th grade high school students the confidence to prepare for a variety of postsecondary career options. VB TECH is

Van Buren Tech (VB TECH), Lawrence, Michigan, is an innovative Career and Technical Education (CTE) institution. As an affiliate of the Van Buren Intermediate School District, VB TECH offers a practical approach to education, instilling in 11th-12th grade high school students the confidence to prepare for a variety of postsecondary career options. VB TECH is - Quality management: Ensuring excellence in advanced manufacturing

Seventy-three percent of respondents stated that they had a product recall in the last five years and 48% said they have experienced more recalls than they did five years ago Quality management is one of those topics that gets more interesting the more you learn about it. You may not realise it but if you

Seventy-three percent of respondents stated that they had a product recall in the last five years and 48% said they have experienced more recalls than they did five years ago Quality management is one of those topics that gets more interesting the more you learn about it. You may not realise it but if you - Medtech: miniature cavity pressure sensors assure quality in plastic injection molding

Direct measurement has become the gold standard for precise cavity pressure measurement in injection molding, where the tiniest deviation from the standard can lead to subpar product quality and even unsafe products. Especially highly regulated industries such as medtech benefit from monitoring product quality to sort out faulty parts automatically and eventually optimize processes. However,

Direct measurement has become the gold standard for precise cavity pressure measurement in injection molding, where the tiniest deviation from the standard can lead to subpar product quality and even unsafe products. Especially highly regulated industries such as medtech benefit from monitoring product quality to sort out faulty parts automatically and eventually optimize processes. However, - Transforming Operations: How AR Is Revolutionizing Industrial Workflows

Augmented reality (AR) revolutionizes industrial workflows to enhance efficiency and precision in operations. Implementing AR technology transforms business processes to improve safety and quality, speed up delivery, reduce costs, and increase employee engagement. The benefits of augmented reality in business, especially for training and maintenance, are substantial and impactful. AR technology provides a competitive edge

Augmented reality (AR) revolutionizes industrial workflows to enhance efficiency and precision in operations. Implementing AR technology transforms business processes to improve safety and quality, speed up delivery, reduce costs, and increase employee engagement. The benefits of augmented reality in business, especially for training and maintenance, are substantial and impactful. AR technology provides a competitive edge - Inspecting the Cleanliness of Plastic Boxes

We ensured a customer, who was troubled by foreign objects and and plastic residue literally stuck by static electricity to toys ready for shipment, could sleep soundly. And not only he, but also the parents of the children who will play with the toys. Why bark up the wrong tree? Let’s look for the source of

We ensured a customer, who was troubled by foreign objects and and plastic residue literally stuck by static electricity to toys ready for shipment, could sleep soundly. And not only he, but also the parents of the children who will play with the toys. Why bark up the wrong tree? Let’s look for the source of - Nikon-AAT3D integration ushers in new era of in-process metrology efficiency and precision

Nikon IMBU and Applied Automation Technologies have announced the successful integration of Nikon’s LC15Dx wireless non-contact laser scanner with AAT3D’s CAPPSNC on-machine metrology software. This innovative combination enables the seamless integration of non-contact inspection within the machine tool envelope while providing wireless data transfer, unlocking a new era of manufacturing efficiency and quality assurance. “The pairing of

Nikon IMBU and Applied Automation Technologies have announced the successful integration of Nikon’s LC15Dx wireless non-contact laser scanner with AAT3D’s CAPPSNC on-machine metrology software. This innovative combination enables the seamless integration of non-contact inspection within the machine tool envelope while providing wireless data transfer, unlocking a new era of manufacturing efficiency and quality assurance. “The pairing of - Getting a head start in the race for EV manufacture

It’s a fast-moving sector characterised by fierce competition and a sense of urgency. This is an industry in a race like none other: the race to produce affordable, sustainable, electric vehicles. This Grand Prix (that’s French for ‘big prize’ by the way) is taking place right now and the entire world is watching in the

It’s a fast-moving sector characterised by fierce competition and a sense of urgency. This is an industry in a race like none other: the race to produce affordable, sustainable, electric vehicles. This Grand Prix (that’s French for ‘big prize’ by the way) is taking place right now and the entire world is watching in the

High-accuracy 3D scanning for traceable quality inspection

This case study explores how high-accuracy 3D scanning technology helps Hubei Shiyan Huaying Mold Manufacturing Co., Ltd. realize a traceable quality inspection. By using FreeScan Trak Pro2 optical 3D measuring and dynamic tracking system, Huaying Mold enhances accuracy, efficiency, and reliability in its manufacturing processes, becoming new benchmark in traceable quality management within the industry.

· Company: Huaying Mold Manufacturing

· Location: Hubei Province, China

· Service: Traceable quality inspection

· Solution: FreeScan Trak Pro2

This case study is also available on YouTube:

Introduction

As modern quality management continues to evolve, the requirements for product dimensional quality inspection are increasing. Efficiency and accuracy are important, yet traceability is also becoming equally essential. This focus on traceability aims to strengthen quality management, reduce error correction costs, and improve overall operational efficiency.

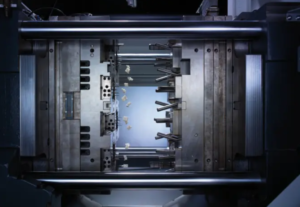

At the forefront of this evolution is Huaying Mold, specializing in lost foam manufacturing—an integral step in mold production. Lost foam casting involves molding foam plastic polymer materials to mirror the structure and dimensions of intended parts. This method has gained prominence in casting due to its cost-effectiveness, environmental friendliness, and ability to produce precise casting structures. Central to the success of lost foam casting is the accuracy of the foam model. The dimensions and shape of the lost foam directly affect the quality of the final cast and machined products.

Recognizing this importance, Huaying Mold has partnered with SHINING 3D since 2017 to continuously enhance its scanning equipment. This collaboration aims to optimize the inspection of product dimensions and shapes, ensuring quality in its manufacturing processes.

3D scanning for traceable quality inspection

Efficient and accurate 3D inspection

Through advanced high-accuracy 3D scanning technology, Huaying Mold has developed a highly efficient and accurate 3D inspection method. Utilizing FreeScan Trak Pro2, currently employed at Huaying Mold, engineers can complete a 4-meter-long lost foam quality inspection in just 10 minutes. Unlike traditional methods, this scanning process:

· Eliminates the need for marker application and removal

· Saves approximately one hour per scan—an exceptional enhancement in efficiency.

After the scan is completed, the data is analyzed in inspection software to compare against design specifications. The chromatograms enable engineers to quickly identify deviations in shape and ensure dimensions fall within required tolerances.

Ensuring traceability through complete 3D data preservation

Upon completion of inspection, the scanned data of the lost foam is meticulously archived together with the inspection report. This archived data remains accessible for future retrieval, facilitating traceable quality management practices.

The scanned data of the lost foam is meticulously archived together with the inspection report.

Benefits of traceable quality inspection

Reducing quality management costs

Utilizing high-accuracy 3D scanning technology, Huaying Mold has implemented a traceable quality inspection method that enables swift and accurate dimensional analysis of products. More significantly, it facilitates a 1:1 restoration of finished product sizes within the 3D data archive, thereby ensuring traceable quality management. This approach holds substantial importance in enhancing Huaying Mould’s operational efficiency and maintaining stringent quality standards.

Traditional dimensional inspection methods for lost foam typically involve measuring key dimensions manually, which is prone to human error and difficult to control, leading to high quality and management cost.

By adopting high-accuracy 3D scanning, Huaying Mold has replaced traditional manual measurements with a scientific quality inspection. This standardized process ensures adherence to stringent standards, and minimizes the occurrence of defective products, significantly enhancing product quality and reducing overall management costs as well.

Maximizing business interests

Implementing a traceable quality management is significant for Huaying Mold’s collaboration with its upstream and downstream supply chains. This method enables swift and accurate tracing and tracking of dimensional quality issues in final castings, facilitating scientific and efficient problem resolution. By minimizing ambiguity in responsibilities within cooperative relationships, Huaying Mold strengthens its partnerships and enhances overall operational reliability.

Conclusion

Throughout years of collaboration, Huaying Mold has improved the efficiency and credibility of product dimensional inspection, and also established a systematic management approach to enhance operational efficiency. Moving forward, SHINING 3D remains committed to advancing its professional technical capabilities, thereby serving as a vital technical support partner for Huaying Mold’s operational success.