In the realm of extreme sports, few events rival the intensity and challenge of the Dakar Rally. Beyond being a mere race, it stands as a testament to human endurance and the resilience of machinery.

Originating in 1978, the Dakar Rally has grown into a global phenomenon, spanning over 5,000 miles of unforgiving terrain, from deserts to mountains and savannas.

Prodrive made its debut in the rally scene in 2020 and has since been a consistent participant in the last three Dakar rallies.

They have earned a well-deserved reputation for their adeptness in designing and manufacturing resilient and high-performing race and rally cars.

Their track record of success speaks volumes about their proficiency in creating championship-worthy vehicles.

A prime example of their prowess is when the Prodrive’s Hunter model clinched the top three positions on a Dakar stage, highlighting the company’s dedication to engineering excellence.

“We need to monitor the health of our vehicles, particularly the space frames” -Paul Doe, Chief Chassis Engineer.

The Dakar Rally stands out as one of the toughest races worldwide, with its challenging terrains and extreme weather conditions.

Ensuring the structural integrity of vehicles is paramount to ensure the safety of drivers and co-drivers. Any damage or abnormalities in the frame could jeopardize the vehicle’s stability, rendering it unsafe for use.

The vehicle’s frame serves as the foundation of its structure, influencing its overall performance. Compromised frames can impact handling, speed, and reliability – crucial factors in the demanding environment of the Dakar Rally.

Regular inspections play a vital role in identifying potential issues early on, allowing for prompt repairs and maintenance. This proactive approach extends the vehicle’s lifespan and reduces the risk of unexpected breakdowns or malfunctions during the race.

Post-rally inspections yield valuable insights into how vehicles have endured the rally’s harsh conditions. These insights inform refinements and improvements in the design and manufacturing processes, driving continuous enhancement and innovation in 3D engineering solutions.

The inspection process of the Dakar frame goes beyond a mere routine check; it is a comprehensive endeavor that underscores safety, enhances performance, promotes longevity, and fuels the relentless pursuit of excellence in motorsport.

Elevating the Frame 3D Data Capturing Process with TrackScan-Sharp

For this task, our local partner utilized the Trackscan-Sharp, a state-of-the-art large-scale 3D scanner, renowned for its advanced capabilities:

This tracking 3D scanning system harnesses cutting-edge optical tracking technology and high-resolution cameras to deliver unmatched accuracy and efficiency in scanning large-scale parts and components.

With a measuring volume of 49m3 and a tracking distance of up to 8 meters, the Trackscan-Sharp enabled capturing the front and sides of the vehicle in a single position, minimizing the need for tracker repositioning and thus saving time while reducing the risk of errors.

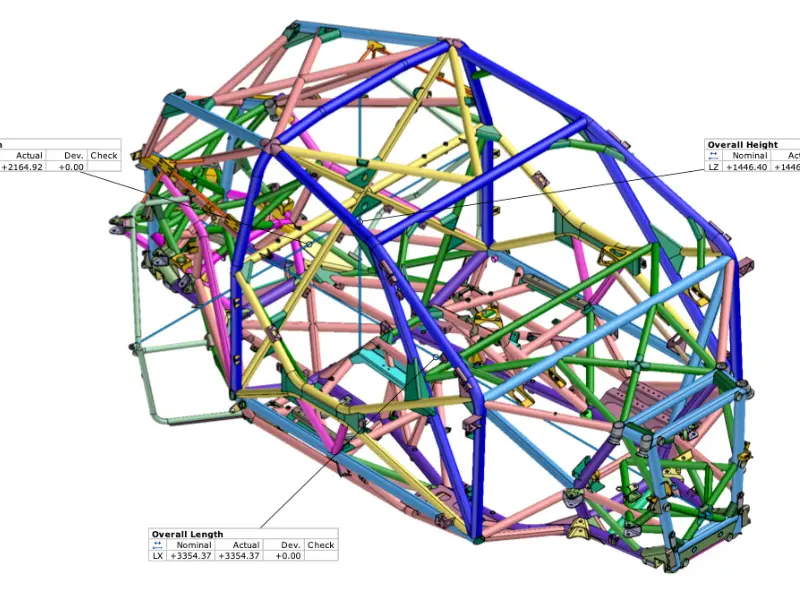

The following step involved a comprehensive inspection of the motorsport frame. By comparing the latest scan data with historical records, any structural changes or potential damage were identified.

Importing the STL file representing the newly captured 3D mesh of the automotive frame into inspection software facilitated a side-by-side comparison with existing records.

This critical analysis allowed for the detection of any deviations or changes in the frame’s structure resulting from the stresses endured during the rally.

Conclusion

The utilization of 3D scanning technology in the realm of motorsport, particularly in race car inspection, represents a significant advancement in efficiency and precision.

The integration of cutting-edge tools like the TrackScan-Sharp has revolutionized the inspection process, offering a seamless and accurate experience for continuous improvement and innovation in race car design and manufacturing processes.