The new kit enables up to 2 microns accuracy for inspection and deformation analysis in aerospace, automotive, and oil and gas industries.

SANTA CLARA, Calif., October, 2022 – Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces the release of the Artec Metrology Kit, a 3D optical coordinate measuring system for high-precision inspection – unlocking deformation analysis and enabling greater accuracy for measuring objects and areas of all sizes.

Available in two versions, Professional and Entry, Artec’s Metrology Kit offers an easy-to-use and extremely versatile photogrammetry solution with metrology-grade precision and high-end accuracy for inspection and reverse engineering.

The Artec Metrology Kit can operate as a standalone optical measurement solution, or as a referencing tool for even better 3D scanning performance over distance. The whole kit is portable, provides high-precision measurements in under 15 minutes, and also has the ability to capture objects in motion – perfect for both on-site and off-site projects.

The Metrology Kit is both DaaKS and VDI certified, and provides point-based accuracy (RMS) up to 0.002 mm + 0.005 mm/m and length measurement accuracy up to 0.015 mm + 0.015 mm/m.

The Metrology Kit includes a camera with resolution of up to 30.3 megapixels and a 28-mm wide-angle lens, measurement targets, adapters, scale bars, and the Metrology Kit plugin, giving users the entire photogrammetry workflow right inside Artec Studio. The kit is also compatible with industry-leading inspection software solutions like Geomagic Control X, PolyWorks, and many more.

“At Artec 3D, we are proud to provide industry-leading metrology solutions and continue to invest a lot of resources into evolving our products and our product line, delivering ever better solutions for our customer base,” said Artyom Yukhin, President and CEO of Artec 3D. “We are confident that the Metrology Kit delivers a most effective solution for inspection projects, where high accuracy and minimal accumulated error are essential. We are excited to see how our users respond.”

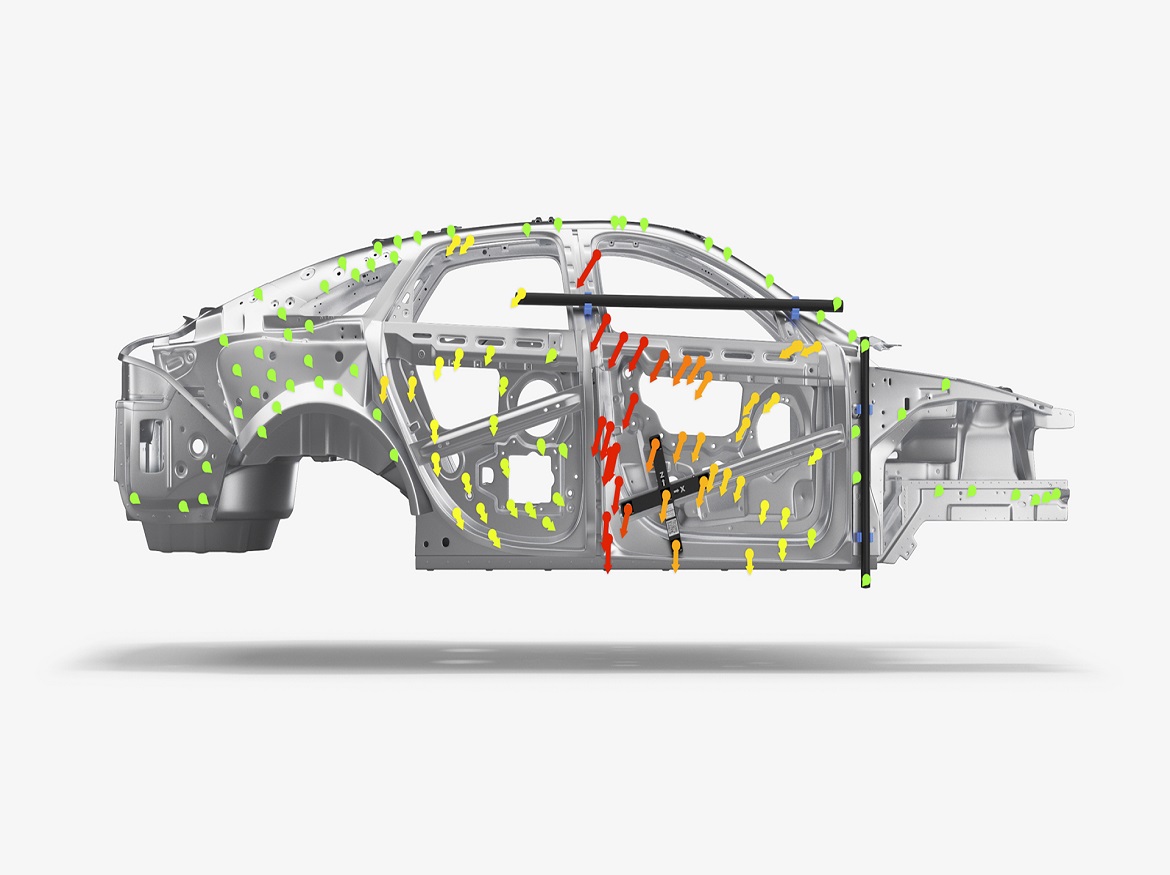

Artec 3D’s Metrology Kit is already being utilized in a range of industries, particularly the automotive industry.

Automotive industry

For quality control in automotive manufacturing processes, the Metrology Kit analyzed the position of welding studs on every fourth chassis in a major car manufacturing production line in Germany, and the results were then used to program their welding robot. Additionally, as part of tests and research for autonomous driving, the kit helped determine the positions of sensors on a car body and correctly place them within the car’s coordinate system.

High-accuracy inspection for aerospace and defense

High-accuracy optical measurement systems are essential for the easy and reliable inspection of large objects such as aircraft components, ships, and wind turbines. With Artec’s Metrology Kit, users can obtain much more precise datasets and confidently perform inspection in use cases where requirements on repeatability are high. This can be at almost any production step – even when the part itself is in motion. For example, UK, German, and Japanese defense organizations use the Metrology Kit for deformation analysis on the main and sub panel systems of large satellite antennas tilted at various angles.

Deformation analysis

The Metrology Kit is perfect for analyzing the geometrical changes of storage tanks, vehicle components, or design prototypes. It can analyze the deformation characteristics of materials under different environmental conditions such as high temperatures and humidity where short measuring time is crucial.

Oil and gas

An ISO-certified German offshore and maritime engineering company surveys and inspects flanges on offshore sites in the North Sea and Baltic Sea. The short measuring time, easy workflow, and dynamic referencing make the Metrology Kit an ideal solution for such high-accuracy applications in unstable conditions. The company measures the flatness and inclination of large flange faces, drill hole diameters, and inner and outer diameters. The full measurement process is carried out within 60 minutes.

Referencing for 3D scanning

The Metrology Kit produces a point cloud with high volumetric accuracy that can be used as a reference to get great 3D scanning results over distance, particularly when capturing large objects or areas with an Artec 3D scanner. Ensuring minimal error accumulation, the kit allows users of Artec Leo or Artec Eva to increase volumetric accuracy by up to 14x.

For more information on the Metrology Kit and its full set of features, visit https://www.artec3d.com/portable-3d-scanners/photogrammetry-metrology-kit