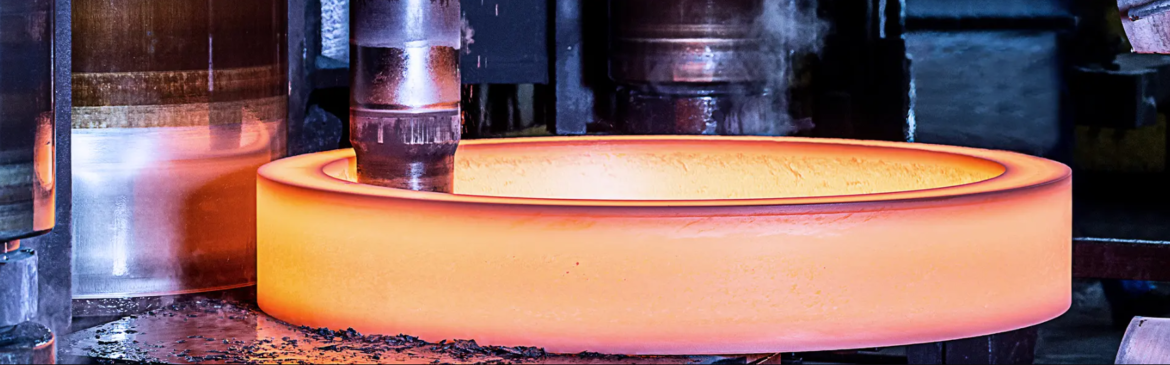

FUNDIDORA ESPECIALIZADA DEL NAZAS S.A. DE C.V. (FENSA) is a leading foundry company in Mexico, specializing in the production of high-quality castings for a wide range of industries.

Known for its advanced manufacturing techniques and commitment to precision, FENSA plays a key role in producing casting components in various sizes and dimensions, often requiring rigorous inspection and quality control measures.

The Challenge: Streamlining Dimensional Inspection

As part of its ongoing efforts to improve production efficiency and product quality, FENSA faced the challenge of accurately measuring large casting components.

The foundry typically produces castings ranging from 0.5 meters to 5 meters in length and width. Ensuring the dimensional accuracy of these parts is critical for maintaining product integrity and meeting customer specifications.

However, the foundry company was in need of a more convenient and accurate solution for dimensional inspection—one that could handle large, bulky parts with varying sizes, while also offering efficiency and ease of use in the factory environment.

The Requirements for a Dimensional Inspection Solution

FENSA sought a dimensional inspection system with the following key requirements:

Fast Scanning Time: The system needed to complete scans in under 5 minutes to minimize downtime on the factory floor.

Wireless Operation: To reduce the risk of accidents and interruptions, FENSA required a device that operated without cables, offering greater flexibility and safety on the shop floor.

High Precision: The inspection system needed to provide accurate measurements with a precision.

Capability to Handle Large Parts: The solution had to be able to scan objects as large as 5 meters in length and 5 meters in height.

Intuitive Reporting: The system had to generate easy-to-understand dimensional reports for FENSA’s engineering team, helping them make informed decisions quickly.

The Solution: Wireless and Intelligent 3D Scanning System NimbleTrack

After evaluating several options, FENSA decided to integrate the NimbleTrack wireless 3D scanning system into its production process.

The NimbleTrack 3D scanning system met all of the company’s key requirements, offering a fast, wireless, and highly accurate solution for large-scale dimensional inspection.

Scanning Process

FENSA’s team prepares the part and positions it in its initial location. Using the NimbleTrack 3D scanner, the scanning process takes just 4 minutes to complete, significantly reducing the time spent on manual measurements or other inspection methods.

Once the scan is finished, the data is processed using 3D software, which generates a comprehensive dimensional report. This report is then delivered to FENSA’s Energy Engineering Area, providing the team with the critical information they need to ensure the part meets the required specifications.

Key Advantages: Speed, Flexibility, Precision, and Versatility

The NimbleTrack 3D scanner’s ability to quickly digitize large and complex parts was a game-changer for FENSA. With its large measurement range and a measurement rate of up to 4.9 million measurements per second, it significantly enhanced efficiency.

The NimbleTrack 3D scanner leverages Scantech’s advanced metrology products and algorithms, achieving exceptional accuracy of up to 0.025 mm and a maximum volumetric accuracy of 0.064 mm. This precision enables users to capture detailed 3D data with industrial-grade reliability.

Thanks to its powerful onboard chips and built-in battery power supply, the 3D scanner and optical tracker are fully wireless, offering true freedom of movement. This wireless design reduces the risk of cable interference and enhances workflow efficiency on the shop floor.

NimbleTrack 3D scanner is highly portable and easy to use. Its compact design makes it ideal for measuring parts in tight or hard-to-reach spaces, offering flexibility and convenience for users in various environments.

Thanks to its compact size, it was possible to perform the complete scanning of the piece within the very limited area that the FENSA client required.

Whether scanning small components or large, complex objects, it consistently delivers accurate and detailed results. This versatility makes it an ideal solution for scanning pieces of different dimensions.

Customer Feedback: Speed and Convenience

FENSA’s engineering team was particularly impressed with the NimbleTrack scanner’s efficiency and versatility. The system’s speed and convenience made it ideal for handling the large parts commonly produced by the foundry.

The customer expressed their satisfaction with the NimbleTrack scanner’s ability to perform dimensional control quickly and effectively, facilitating routine inspections tasks.

In fact, FENSA’s team mentioned that, while they had seen a similar demonstration with a different system, the NimbleTrack scanner was the first one they had encountered that combined speed and convenience in such an intuitive package.

A New Standard for Dimensional Inspection

The introduction of the NimbleTrack scanner at FENSA has not only optimized the dimensional inspection process but also improved overall production efficiency.

By reducing scan times, eliminating cable-related risks, and providing accurate, actionable reports, the NimbleTrack system has proven to be an invaluable tool for FENSA in its pursuit of manufacturing excellence.

With the success of this integration, FENSA is now looking to expand its use of NimbleTrack technology for further dimensional control and reverse engineering applications, setting a new standard for inspection processes in the foundry industry.