Parts made of metal are accurate to a tenth of an inch in some plants. In different plants, there are items that can’t endure size contrasts of even a couple of millionths of an inch.

Making parts to either resilience range is incomprehensible without exact gaging. Notwithstanding, exact gaging is incomprehensible assuming freedoms are taken with the plan, dealing with, and support of accuracy estimating instruments.

Defending your measurements against inaccuracy will be easier if you are familiar with the following nine major enemies of precision gaging.

Wear | This is the adversary that is most frequently overlooked. For instance, direct estimations are normally connected among gaging and workpiece surfaces. Every time it is used, the gauge gets a little worn out, and the inaccuracy gets worse over time. Additionally, wear causes spherical and gage contacts to flatten, resulting in discrepancies. Systematic checking and calibration against precise masters is the most effective treatment for gauge wear.

Dirt | Numerous estimation mistakes can be followed by somebody’s grimy hands. The people who measure in millionths of an inch ought to surpass even careful guidelines of tidiness. This applies particularly to individuals who just can’t wring gage obstructs together without utilizing what is known as wrist oil, a combination of pore gushing, skin particles, coarseness, oil, and coolant, that coats gaging surfaces with a concrete-like slop going from 0.00005 to 0.0005 inch in level. Dirt abrasion also accelerates wear and results in internal looseness.

Looseness | The typical client of gages will in general ensure the significant screws, nuts, and braces are secure. Notwithstanding, inner detachment brought about by wear might trick the client. Gage platens and bracket arms may, for instance, creep, or a workpiece may not fully settle into place. The way to diagnose detachment is estimation redundancy. On the off chance that a similar perusing doesn’t come up two times, or on the other hand on the off chance that a demonstrating meter hand ripples waveringly, detachment is the reasonable guilty party.

Deflection | Deflection is always present and active, and it can only be felt or seen by special means. In his third law of motion, which states that every action has an equal and opposite reaction, Isaac Newton talked about deflection. Picture driving a chamber into a gage. Albeit the contacts separate to acknowledge it, the inner cinching power of the axle acts similarly against the edge, in this way making it redirect somewhat. The frame deflection, the workpiece, or both are being measured.

Gaging Pressure | This power should be sufficiently weighty to have steady power, but not so weighty as to misshape the workpiece. Pressure mistakes quite often originate from a lot of instead of too little power.

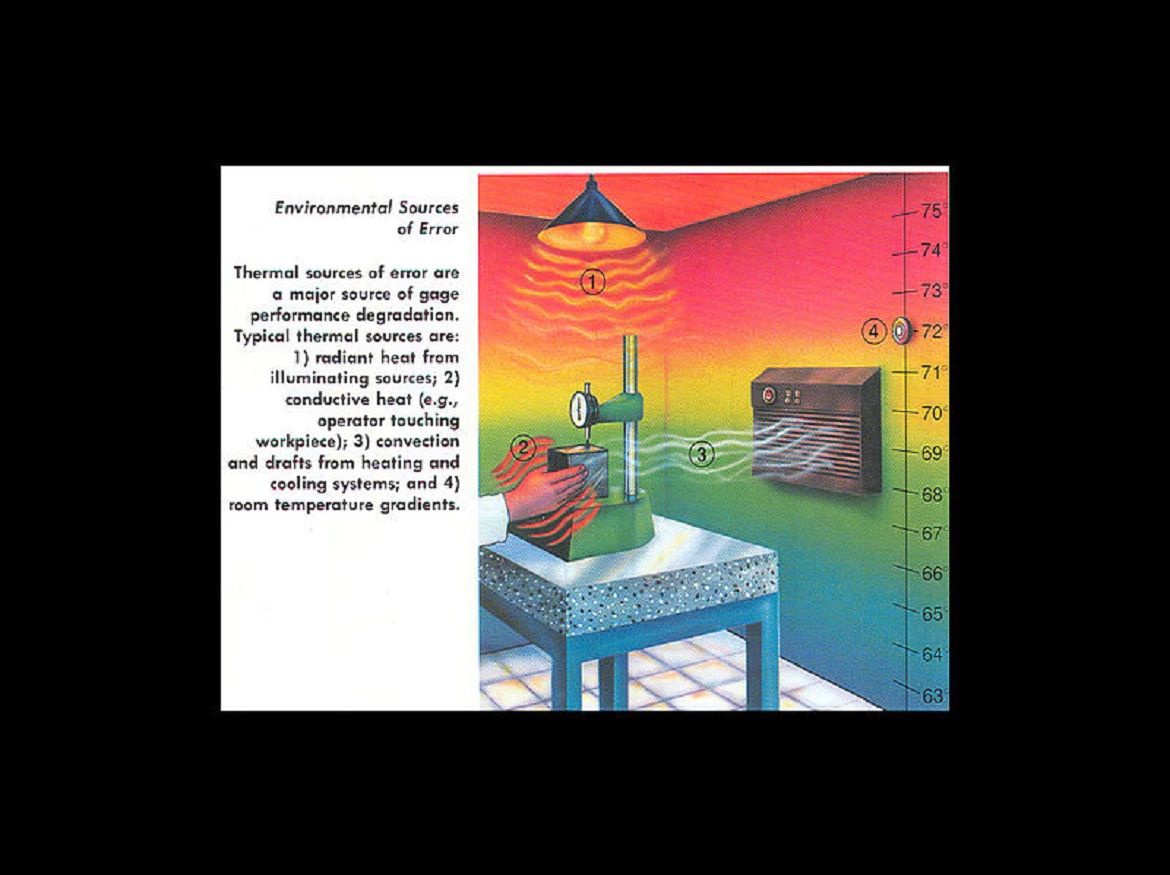

Temperature | Everybody concurs that a workpiece is greater when it’s hot. Any move initiated to lighten this typically includes cooling the part a lot at the closest water fountain. There ought to be a major blazing sign in each accuracy gaging region that peruses: ” Keep the temperatures of the workpiece, gage, and expert the equivalent.” There is likewise a propensity to place estimation hardware in areas that cripple their viability. A few most loved spots incorporate close to radiators, in the immediate beams of the midday sun, or almost an entryway that is opened and closed multiple times on freezing days.

Vibration | Some individuals place a “millionth” comparator close to an aisle that forks trucks use. Others place them close to air blowers or pounding punch presses. The moral is: to perform precision work in areas where your comparator won’t jitter.

Geometry | Estimation should be square to the hub. This is rudimentary, nearly to silliness. By the by, it brings up a significant wellspring of mistakes. Whether the instrument is a hand device or an interferometer, numerous administrators continue positioning the workpiece or squeezing the gauge barely to the point of finding an off-base solution.

Approximation | A glance at any mechanical micrometer perusing shows where this foe sneaks. Maybe it peruses 0.494 inches — and somewhat more. Which of the following best describes the “little more”: 0.4942, 0.4943, 0.4944, or 0.4945 inch? Do you involve this as though it were genuine perusing? Estimation probably wastes more time and money than all other measurement errors combined in rejections, salvaging, disputes, and correspondence. The standard fix is to get an instrument with higher amplification, or one with a precise scale partitioned all the more intently. Moving to a digital readout is an additional option.

There are additional known causes of gaging error, and more are still unknown. Notwithstanding, the firm that handles this rundown will have moved toward more noteworthy accuracy and precision.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.