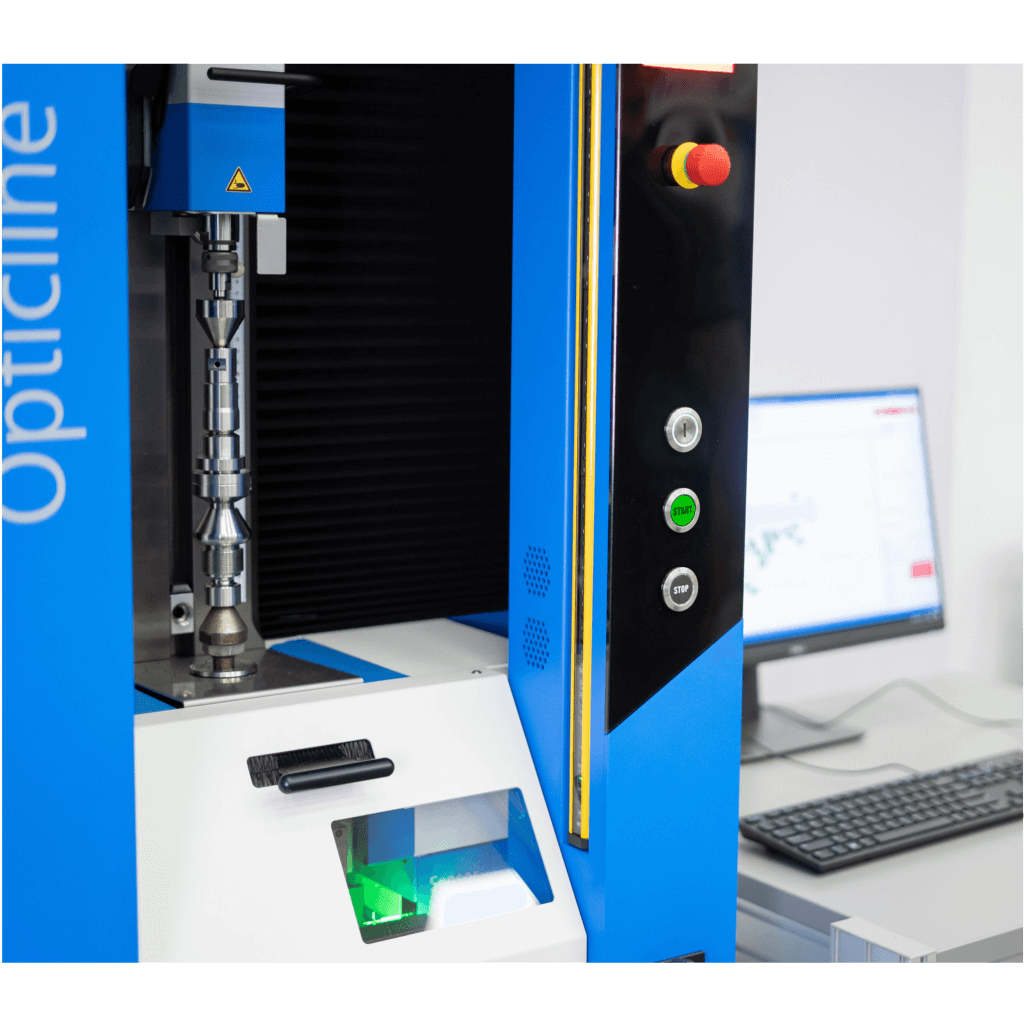

Jenoptik Opticline Range

Robust, shop floor optical shaft metrology at its simplest, fastest, and most accurate.

Shop floor metrology solutions able to operate safely and accurately at high speed with reliable results. Cylindrical parts measured in seconds, with full reporting, with confidence.

Overview

The Opticline range is designed for extremely fast, extremely accurate measurement of cylindrical or shaft-type parts. It uses green light received by cameras to take a full image of the part to provide dimensional and characteristic measurements – such as concentricity and runout. The range has many applications in the automotive, medical and turned parts industries.

Features

- Rapid Return on Investment ROI: The Opticline saves time by removing the bottlenecks from the measuring room.

- Accurate: Most accurate system on the market using new state-of-the-art optics with accuracies of 1micron.

- Reduces Human Error: Measuring results do not depend on or adjust from, operator intervention.

- Robust: We have systems in the UK that have been working 24/7 for 20 years and are still in action today.

- Easy to use: Simple for any operators to use with rapid results and reporting.

- Flexible: Little to no set-up times, even with frequently-changing workpieces.

- Cost-effective: Reduces waste, saves time, and increases throughput.

- Hi-Resolution: Great at measuring those hard-to-see features like small radii and chamfers.

Applications

- Automotive industry: Measurement of turbochargers, engine valves, pistons, camshafts and crankshafts, gear shafts, and driveshafts.

- Turned and ground parts producers: Measure shaft-shaped, largely axially symmetrical workpieces.

- Medical technology: Measure implants, bone screws, and rotating instruments.

To know more, check The Sempre Group.