PC-DMIS 2022.1 connects quality, automation and reporting for smarter manufacturing

PC-DMIS 2022.1 extends its reach with a range of new features to connect and drive smart manufacturing with a seamless flow of quality data. From robotic cells to business-wide reporting, the latest release joins up every part of your organisation with critical measurement data. For the PC-DMIS pros, new features and additional hardware support simplifies part inspection and streamlines measurement workflows.

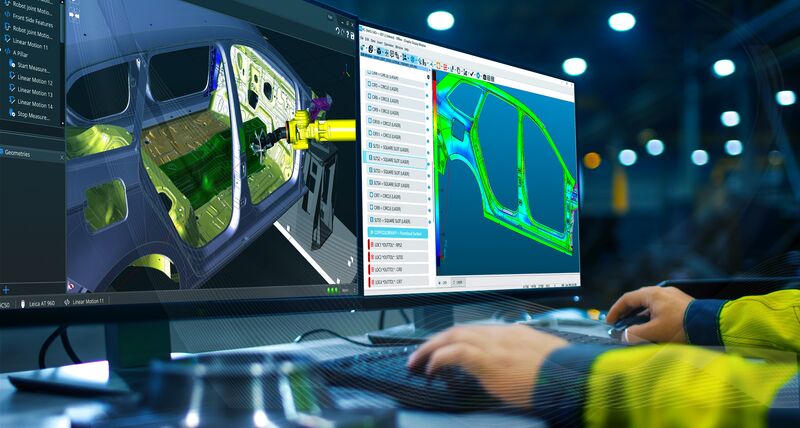

New: Connect to HxGN Robotic Automation as Metrology Client

PC-DMIS is now seamlessly integrated with HxGN Robotic Automation. Use PC-DMIS as the primary metrology software for inspection and analysis within automated cells to significantly increase measurement capacity, repeatability and quality.

HxGN Robotic Automation scans parts and delivers data to PC-DMIS for analysis and reporting. Single click synchronisation with part CAD data creates the robot path that will be used for data acquisition and part inspection, reducing the time required for offline programming of robotic measurement programs.

Results can also be transferred to our Q-DAS and eMMA ranges for organisation-wide process control and optimisation.

Find out more about HxGN Robotic Automation

New: Connect PC-DMIS to HxGN Metrology Reporting

PC-DMIS measurement report data now integrates directly with the HxGN Metrology Reporting platform for aggregated information, visualisation and insights.

Anyone with appropriate access and a connected device can view the status of a measured part and the corresponding PC-DMIS metrology report in an intuitive, cloud-based application.

The latest integration helps teams to share key reporting data with colleagues without the need to attach reports to an email. Apply rules and receive alerts and notifications for the latest updates on any measured part.

Find out more about HxGN Metrology Reporting

New: Constructed features from Point Cloud and Mesh Data

The latest release of PC-DMIS further expands the types of constructed extracted features available. Now you can extract features from a Point Cloud or Mesh without a laser probe license. Import Point Cloud data from other systems or routines to quickly create Round and Square Slots, Cones, Cylinders and Spheres. Now you can enjoy the same functionality as the equivalent laser auto features but with added flexibility.

New: Touch Screen Integration for PC-DMIS with new RA8 Arm Wrist Display

Hexagon’s RA8 Absolute Arm portable CMMs wrist displays show communications from PC-DMIS when measuring features or executing a measurement routine. The latest wrist display (Version 2) is now fully interactive – with a touch screen which supports swipe and tap gestures.

Through a handy Quick Access Menu (QAM) users can change settings, confirm or delete the last measured point or even cancel a measurement routine. Messages from PC-DMIS show on the wrist display and the operator can easily scroll through text with intuitive gestures. That means fewer interruptions and trips back to the computer to view messages or adjust settings.

Find out more about RA8 Absolute Arm

PC-DMIS 2022.1 offers many other new features and improvements, including:

- NEW: add or remove hits from the Measured Feature dialog window

Simplified, visual editing of measured feature points. Improves editing capability for previously created measured features. - NEW: registry settings now in JSON file

All PC-DMIS and related interfaces settings created in the Settings Editor are now stored as a JSON file rather than the Windows Registry. - NEW: 4 axis scanning support on B5 Controller

Enjoy faster, more flexible scanning for analogue probes. New 4 Axis scanning on B5 Controller opens up a new range of new scanning options. - NEW: Incremental Rotary Table Relative Moves

Enter incremental values to an existing rotary table position. E.g., add 30° to an existing rotation of 300° to create a new table position of 330°. - NEW: support for HP-C-T CMM Camera Module

PC-DMIS now offers sensor support for HP-C-TS5.10, enabling high throughput for applications where image capture is faster than tactile probing.

+ much more – see features and benefits section below for details.

PC-DMIS is a highly flexible and widely adopted metrology software. It comes as standard on all Hexagon’s Manufacturing Intelligence division’s measurement devices. It is also available as a retrofit package for most other measurement equipment manufacturers’ machines, allowing users of non-Hexagon equipment to take advantage of PC-DMIS technology.

Click on ‘Features & Benefits’ to learn more about the other new features, capabilities and improvements that have been introduced in the 2022.1 release.

To ensure our customers can use the latest features, download the latest updates and continue with maintenance updates, we recommend the purchase of a current Software Maintenance Agreement (SMA). The SMA also provides access to ongoing technical support and service.

Features & Benefits

NEW: Add or remove hits from the Measured Feature dialog window

Easily add or remove hits directly from the Hit Targets area of the Measured Feature dialog window with simplified, visual editing. Simply add a new hit and drag to the desired location using the mouse.

Additional hits are created as a copy of the selected hit. They can be dragged to the new location in the graphics window or coordinates can be entered manually. This Improves existing editing capability for previously created measured features.

NEW: Registry settings migrated to JSON file

PC-DMIS and related interface settings generated in the Settings Editor are now stored as a JSON file. Previously, they were stored in the Windows Registry which occasionally caused access issues for some users. JSON files are easy to access and are independent of the operating system.

NEW: 4 axis scanning support on B5 Controller

Faster, more flexible scanning for analogue probes on B5 Controller enables a wide range of Classic scans including Linear Open and Close, Section, Perimeter and Freeform Scans. Auto Feature Scanning is also supported.

NEW: Incremental Rotary Table relative moves

For added speed and convenience, rotary table users can now add incremental values to an existing position. For example, add 20° to an existing rotation of 200° to create a new table position of 220°.

NEW: Support for HP-C-T CMM camera

PC-DMIS is now compatible with HP-C-TS5.10, the non-contact camera sensor for soft or easily deformed parts or small features which are difficult to probe with tactile sensors. A winning combination for high speed capture and measurement from digital images.

NEW: MAC (Manual Application Changer) Sensor support

The new MAC integration enables PC-DMIS to automatically replace an indexable motorised head with a scanning probe during a measurement routine.

Now in PC-DMIS 2022.1 you can easily switch between versatile indexable probe heads and high precision fixed HP-S-X5 probe heads for increased speed and reduced CMM downtime.

NEW: Point Cloud Intensity Filter

Visualise intensity values from Point Cloud (CoP) data where supported. Use the slider to set a range between minimum and maximum intensity values. Now you can easily distinguish between different surfaces and identify and isolate components in your point cloud data.

NEW: Optical Zoom improvements

Pixel size is now used for measuring Optical Magnification in PC-DMIS Vision. From a metrology perspective the image pixel size is a more useful value than the optical magnification, making it easier to understand the potential accuracy of a measurement.

IMPROVED: Enhanced Excel results with macros

Create Excel report templates with macros to automate tasks such as colour coding cells to indicate tolerance. e.g., red, amber and green. Excel macros enable users to easily customise their report template with additional formatting, edits or formulae.

IMPROVED: Optimised Probe Parameter handling

The required parameters for the type of probe referenced in the Load Probe Command are now automatically loaded. This new improvement avoids the need to insert an Opt Probe command into the routine which previously required loading a separate file and entering values in the registry. This saves time during set up of measurement routines when probe change is necessary.

NEW: VWMP (Volkswagen Measurement Principals) for flush and gaps

Panel gaps are the most immediate indicator of overall quality for vehicles. In PC-DMIS 2022.1 you can now measure flush and gaps in line with VWMP specification – a welcome feature for sheet metal measurement.

The CAD selection, visual tools and programming guidance are based on the same concept of standard F&G Auto Feature to help existing PC-DMIS Laser users who are new to VWMP

IMPROVED: Quick Measure Toolbar improvements

New Transform CAD icon added to the CAD Setup toolbar and the CAD pulldown section of the Quick Measure toolbar. Dropdown toolbars now remember their last selected state when switching between multiple open measurement routines.

Technical Data

Operating system

PC-DMIS 2022.1 operates under 64-bit Windows 10, Windows 8.1, Windows 8, Windows 7, and Windows Vista. No other operating systems are supported.

- For HP-L systems and systems that use RS-SQUARED sensors that run PC-DMIS in DCC mode, you need to use a 64-bit Windows 10 Pro Computer with up to 4 Cores. You can find a list of supported operating systems for most versions of PC-DMIS here: https://support.hexagonmi.com/s/article/Windows-OS-Compatibility-Listing-for-PC-DMIS

- When you use third-party drivers, you should contact your local Manufacturing Intelligence representative to ensure operating system compatibility.

- Running PC-DMIS inside a Virtual Machine (VM) is supported only if the VM supports OpenGL 3 or higher.

- PC-DMIS Vision machines do not support 64-bit Windows 8. The Matrox Frame grabber PC-DMIS Vision hardware component does not support a 64-bit operating system.

Microsoft .NET Framework If you do not have Microsoft .NET Framework 4.6.1 for Windows, the PC-DMIS installer will install it for you. RAM 4 GB of RAM or higher

- The size of the CAD data file and the tessellation multiplier value used affect the amount of memory needed. These both affect the number of tessellated facets needed to display the model. The smaller the tessellation multiplier value used, the more memory needed for the facets. For large CAD models, this could cause an “Out of Memory” error. If this occurs, the current PC-DMIS session will be left in an unstable state and should be terminated.

- The default tessellation multiplier value is 1.0. Setting a tessellation multiplier of 0.1 will result in a 10 to 20 percent increase in the memory required over the default value of 1.0. Decreasing the tessellation multiplier further to 0.01 will result in an additional 50 to 65 percent increase of memory required.

1 GB of video RAM 64 GB of RAM Dual-Channel @1063 MHz DDR4-2666 MHz ECC RDIMM memory (for HP-L systems and systems using RS-SQUARED sensors) CPU

- 2 GHz or higher quad core processor

- Intel Xeon W-2223 Processor (3.6GHz, 3.9GHz) for HP-L systems

- Intel Xeon Processor E3-1505M (3.00 GHz) for systems using RS-SQUARED sensors

- Intel Core i7 9th Generation or higher (for example, i7-9xxxHx) 6 Cores hyper-threading enabled (for HP-L systems and systems using RS-SQUARED sensors)

Graphics Compatible with any popular graphics card that meets or exceeds the following suggested minimums:

- GPU Memory 2 GB DDR3*

- 6 GB Memory Bandwidth 29.0 GB/s (for HP-L systems)

- Memory Bandwidth 29.0 GB/s

- CUDA Cores 384

- Open GL 3.0

- NVIDIA Quadro P5000 (4 GB) (for HP-L systems and systems using RS-SQUARED sensors)

- AC or AX type Wi-Fi card for systems using RS-SQUARED sensors

* For an RS4 laser sensor or later model, you need to have a GPU with at least 4 GB DDR3. The graphics driver must support OpenGL 3.0 or higher. A warning message appears on PC-DMIS start-up if the driver does not support OpenGL 3.0 or if your graphics driver is more than three years old. Hard drive 2 GB of free hard drive space plus allocated virtual memory of eight times the largest CAD file used. SSD drive, HDD 10K, or two disks in RAID 0 mode (high-performance hard disk drive).

128 SSD, 128 SSD RAID, 1 TB HDD Display Screen resolution of 1920 x 1080 or higher Connectivity

- One Serial port

- Three Ethernet ports. This may be required for specific installations in consideration of local needs, including but not limited to CMM systems where one port is required for controller communications and another for intranet/internet communications.

- Two USB ports

- A properly configured LMS license or a HASP key (a physical USB portlock)

- LAN port with Intel Chipset (for example, I219) (for HP-L systems)

Note: A HASP key does not act as general purpose data storage; therefore, you cannot use a HASP key to store (download) arbitrary data from a computer. Similarly, you cannot use a HASP key to put (upload) arbitrary data on a computer. Also, only Hexagon applications can read or write to a HASP key; other applications do not have this capability. As a result, you cannot use a HASP key to load and unload data to and from a computer.

Browser Internet

Explorer 10 or later

Anti-virus software

Hexagon used the Sophos anti-virus tool to test PC-DMIS 2022.1. The user will need to confirm the performance of any other anti-virus tool. Solutions for CMMs using RS-232 communications If you are installing PC-DMIS 2022.1 on a new or existing computer, but you have an older CMM model that uses RS-232 communications, then you will need to install one of these solutions on your computer:

- An external RS-232 serial-to-USB adapter cable plus the serial-to-USB adapter cable driver

- An internal serial adapter card with serial ports

Browser

Internet Explorer 10 or later Anti-virus software Hexagon used the Sophos anti-virus tool to test PC-DMIS 2022.1. The user will need to confirm the performance of any other anti-virus tool. Solutions for CMMs using RS-232 communications If you are installing PC-DMIS 2022.1 on a new or existing computer, but you have an older CMM model that uses RS-232 communications, then you will need to install one of these solutions on your computer:

- An external RS-232 serial-to-USB adapter cable plus the serial-to-USB adapter cable driver

- An internal serial adapter card with serial ports