What’s the most efficient way to ensure the quality of millions of mass-produced series parts used in highly demanding, safety-critical applications? Plogsties meets this challenge by putting its trust in vision systems from Kistler for optical quality inspection – the key to zero-defect production backed by technical advice, state-of-the-art image processing, and all-round service.

A chain is only as strong as its weakest link, so the popular saying goes. Figuratively speaking, this also applies to supply and value chains. Many components – even the very smallest ones – travel halfway around the world before they reach their destinations in applications such as safety belts. ‘This tiny component saves lives,’ says Andrea Leicht, Managing Director at Plogsties GmbH in Reinbek near Hamburg, Germany. ‘It’s installed near the safety belt in a car. If the safety belt deploys in case of an accident, this component must be technically faultless.’ The component in question is the rivet for the seatbelt buckle, which is connected to the entire seat by a steel cable to ensure the crucial grip.

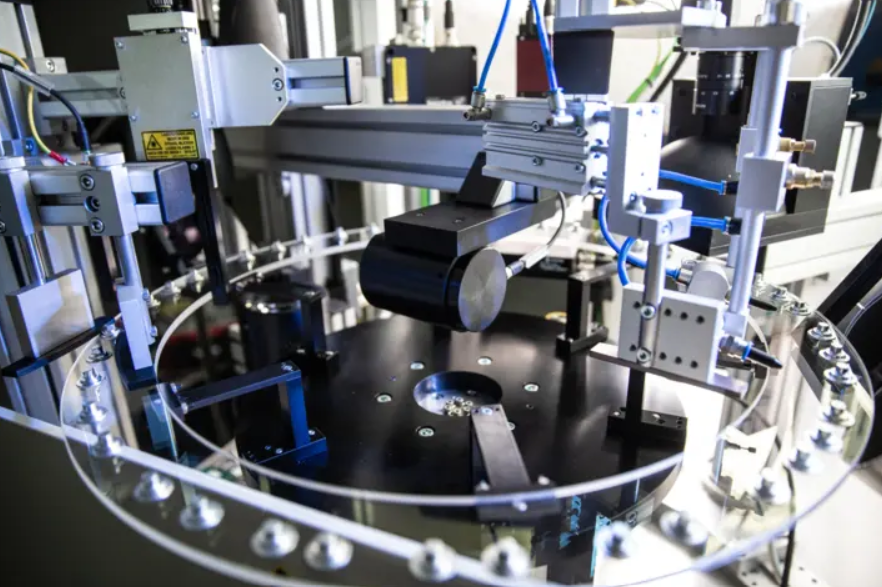

The people at Plogsties know a thing or two about series parts and fasteners such as these. Their portfolio includes cold forging parts, stamping parts, precision turned and milled parts, laser and welding parts, heat treatment systems – and much more besides. Many of these products are used in airbag and safety belt systems for the worldwide automotive market. Plogsties also supplies customers in the industrial vehicles and escalator sectors. Udo Plogsties founded this family firm back in 1983, together with his wife Monika. Since then, their two daughters have taken over management of the operational business – which currently has 64 employees and activities in 36 countries. ‘We inspect and sort around 420 million parts each year to ensure they meet the quality requirements. Zero-defect is absolutely critical so we can guarantee maximum customer satisfaction. And to achieve that, we have Kistler as our valuable – and really very strong – partner,’ Leicht points out. Together with Kistler, Plogsties has grown consistently since 1994. The company now operates 23 inspection systems from the Swiss measurement technology expert to guarantee 100-percent quality assurance.

From consulting to commissioning and retrofits

When it comes to vision systems, Kistler’s policy is to have the key skills available in house. In particular, these include image processing know-how and expertise in special-purpose mechanical engineering – plus KiVision, the company’s proprietary image processing software that was developed specifically for quality assurance and is constantly adapted to increasing requirements in a variety of industries. It goes without saying that Kistler’s vision systems also leverage the latest camera and image processing technology to check parts for parameters such as dimensional stability, contours and surface quality. As a full-service provider, Kistler supports its customers throughout the value chain – from the design phase and the feasibility analysis to plant construction and commissioning, ongoing adaptations during operation, service, and retrofits. Advisory support and service are especially important for customers – a point highlighted by Samuel Ganzhorn, Sales Manager Vision Technology at Kistler: ‘Customers come to us with the part to be tested – the job to be done. We then launch an intensive consulting process when we work together to clarify what matters to them. We establish which length dimensions, diameters or surface defects are relevant – the ones that our inspection systems have to detect. And then we investigate in depth to find out which technology will be best – and most cost-efficient – to get the job done.’

In the image processing laboratory at Kistler’s site in Straubenhardt (Germany), highly qualified employees and cutting-edge technologies are standing ready to tackle the challenges their customers face. The facilities here include classic and 2.5D image acquisition, Shape from Shading and, of course, 3D technology. Work is constantly in progress at Kistler’s Competence Center in Karlsruhe to continue developing these technologies – including both software and hardware for optical quality inspection. Ganzhorn takes up the story: ‘We also tell our customer if something can’t be done in the way they want, or if we believe that it doesn’t make sense. I frequently hear feedback from customers who say this is exactly the kind of honesty they appreciate. Nevertheless, we often find a possible solution, another variant – a way to accomplish the job that ensures high satisfaction.’

Optical quality inspection aided by cutting-edge technology

Kistler also meets all its customers’ wishes as far as mechanical engineering is concerned. The automatic vision systems, which have a modular structure, are usually implemented as standalone test cells – but they can also be integrated directly into production lines when necessary. State-of-the-art engineering (including simulation) ensures that customers receive the optimum solution in terms of mechanics, electrics and software. The vision systems are tested intensively both at Kistler’s premises (using customers’ parts) and at the customer’s site (with support from Kistler) before they commence many years of intensive operation that often involve inspections of gigantic quantities. In the post-commissioning phase, Kistler is still on hand to assist its customers with technical support (both remote and on-site), training, and efficient supplies of spare parts.

‘Kistler always offers us the latest technology that’s available on the market. And we too take the same approach so we can pass the advantages of this technology on to our customers,’ says Roman Kraus: he began working at Plogsties 23 years ago, and is now responsible for operating the testing systems together with his four-strong team. ‘By drawing on our experience, we’re often able to convert the systems to new parts ourselves. But if necessary, Kistler can always be called in. What’s more, necessary adjustments can often be performed remotely. A retrofit – with a module for hardness testing, for example – also presents no problems. And yet another very positive aspect of Kistler is that hardware and software come from one single source, so we have one contact for everything.’

The KiVision software makes it easy to set up optical quality inspection; it offers a vast range of tools and macros, and accuracy down to the μ-range is guaranteed thanks to powerful sub-pixel algorithms. Other possibilities include connection to MES systems, the company network, and operation on PC workstations. On the hardware side as well, there virtually no limits to customer’s wishes that can be met. Kistler’s vision systems are based on certain basic types, but they are customized according to the specific inspection task by adding features such as a rotating glass plate, robot handling, or individual feeding and sorting.

Zero defects thanks to 100-percent inspection

At Plogsties too, development never stops – and all signs are still pointing to growth. An older system from Kistler is currently being replaced by a new one – another feature of the portfolio in cases where it is no longer sufficient to retrofit a vision system. Since the acquisition of a screw manufacturer in Turkey back in 2011, Plogsties has also been producing parts itself – and the company is constantly entering into new areas of expertise: licenses for special fastening technology solutions are just one example. Thanks to the skills it has built up over decades, Plogsties also supports its customers with designing new parts, and even with engineering. Emphatic final words from Andrea Leicht: ‘We definitely intend to continue growing with Kistler. Personal contact is very important for us. The fact is that we can only guarantee 100 percent testing and zero defects in the long term if we have Kistler on board!’