Winterthur, October 2024 – Visitors to the SPS 2024 (November 12 to 14 in Nuremberg, Germany) will have the chance to experience user-friendly production measurement technology for every process step: at the SPS 2024, Kistler will showcase its customizable solutions for process monitoring and quality assurance in demanding industrial production applications at booth 410 in hall 7A. On display will be a broad portfolio ranging from sensors and amplifiers to integrated mounting solutions. This includes innovations such as the KiTorq 4552A torque flange and extended versions of the maXYmos TL, NC and BL process monitoring systems.

The Kistler solutions featured at the SPS 2024 allow users in the e-mobility and electrical engineering industries to design process monitoring systems, optimize manufacturing processes with a special focus on resource efficiency, and precisely test the performance of finished products.

Simple and accurate torque and angle measurement with the new KiTorq torque measuring system

The new KiTorq 4552A measuring system for development and EOL testbench applications analyzes the efficiency of electric drives or pumps by measuring not only the motor’s torque, but also its speed and angle of rotation. It provides highly accurate torque measurements at up to 30,000 rpm and can determine the angle of rotation to within 0.01° – thanks to its integrated angle sensor, which saves valuable bench space. The KiTorq 4552A records data in two calibrated measurement ranges which can be defined individually. Users can transfer collected data via Ethernet and fieldbus interfaces, which also helps preventing external interference and data loss.

In addition, Kistler has increased the air gap between the rotor and stator to up to 5.0 millimeters and eliminated the interfering antenna ring, making it easier to access for maintenance purposes and to replace the rotor and stator. The torque measuring system can measure up to five rotors simultaneously. The rotors and stators are calibrated separately, but their parameters are swapped automatically. This means that users do not need to perform any further calibration and can quickly and easily continue their measurements.

Production measurement technology with flexible connectivity options for precise data acquisition

At the event, Kistler will also highlight further solutions for simple and precise data acquisition in a wide range of production environments. The ICAM-B 5073B charge amplifier offers individually configurable channels, and calculates and weighs the input signals, allowing it to be adapted precisely and flexibly to the user’s requirements. Machine monitoring based on process thresholds defined in the ICAM-B can help prevent unexpected failures, reduce downtime, and extend machine life. The handheld charge amplifier family includes the 5811A00 and 5811A01 mobile units – each with a built-in charge amplifier, integrated data acquisition and optional insulation testing. These two features make it possible to compare and verify data from sensors in the machines directly on the shopfloor, without the need for time-consuming disassembly. The measured values can not only be recorded and stored in the unit but can also be displayed directly as a graph on the integrated touchscreen. In turn, the strain gauge amplifier 4709A with IO-Link interface features a robust design for extreme environments and offers a low-pass filter, peak value memory, and sample-andhold function, as well as advanced diagnostics and fault detection for accurate, reliable data acquisition with a sampling rate of 8 kS/s and ADC resolution of 24 bits.

Customized joining systems for demanding applications

At the SPS 2024, Kistler will also present two examples of electromechanical joining systems that can be used as individual components or as complete systems integrated in a Smart Single Station. Like all electromechanical systems from Kistler, the NCFE 2/5 joining module is particularly energyefficient, especially in comparison to pneumatic versions. Thanks to its integrated sequence control, it is also exceptionally user-friendly and allows quick and easy integration into the process environment. The NCFE 2/5 is, for example, ideal for fitting magnets and bearing presses for electric motors. The NCFC joining module, which will be demonstrated in a clinching application at the booth, features a compact and lightweight design allowing users to deploy it even in confined production environments or moving robotic arms.

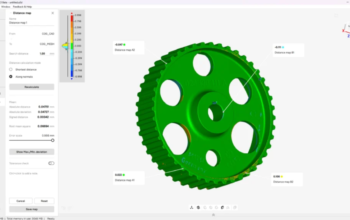

Enhanced functionalities of the latest maXYmos process monitoring systems for even higher product quality

Complex testing and assembly processes can be precisely monitored with the members of the maXYmos family, which can also be used to assess product quality.

The maXYmos 1.9.2 TL / NC version includes reset-measure-jump compensation for small force measurements, as well as separate taring for the sensors and an enhanced envelope curve function for steeper slopes. The system also offers an extended license package that doubles the number of evaluation windows available for even more accurate process monitoring. User-friendly multi-point calibration with up to 31 calibration points increases the linearity of force measurement over the entire measurement range, allowing measurements to be more precisely matched to process requirements. Features such as the revised LDAP, OPC UA interface, audit trail and QualityWorX integration ensure centralized user management and easy integration into existing structures.

The new maXYmos BL – 5867C process monitoring system will join the maXYmos family in the first quarter of 2025, bringing significant improvements. The larger, capacitive display combines better readability with improved ease of use. The new USB port enables convenient transfer of backup/restore data and storage of recorded measurement data, while also supporting barcode readers. New are also licenses that allow the device functionality to be expanded into new areas: access protection with individual user groups (also via LDAP function), IloT connectivity via OPC UA, as well as a sequencer mode, support integrated process control. The latest generation of the process monitoring system focuses on system integration via Industrial Ethernet.

Customized measurement data analysis solutions with MaDaM and jBEAM for machine manufacturers and end users

Kistler’s measurement data management software MaDaM and measurement data analysis and visualization software jBEAM are reliable partners for evaluating all collected data. Not only are they excellent choices for managing and evaluating manufacturers’ own data; machine builders can also integrate them into their machines as analysis templates. Working together with Kistler’s experts, customized templates can also be developed and delivered with the machine. The templates allow end users to perform interactive measurement data analyses, benefit from automatic report generation, and create guides to lead users through the analysis. The service is also available at SPS.