Increasing demands in quality assurance for high quantities presented the German company Prefag with new challenges in the production of its precision turned parts. Mahr provided the solution with a MarSurf Series 1200 CNC measuring station.

Since 1954, Prefag Carl Rivoir GmbH & Co KG from Walzbachtal/Germany has been manufacturing complex machined parts and assemblies based on them: from short and long turned parts for precision mechanics to assemblies with sophisticated joining and connection technologies including further processing such as heat and surface treatments. Customers from the industrial, automotive, medical technology, aviation, rail vehicle, marine and sensor technology sectors are increasingly demanding end-to-end control of the products they manufacture.

“In order to meet our customers’ requirements, we were looking for a long-term solution,” says Christoph Eichner, Quality Management Officer and Head of QW at Prefag. A higher degree of automation with simultaneous ease of operation was also required.

MES offers the right concept

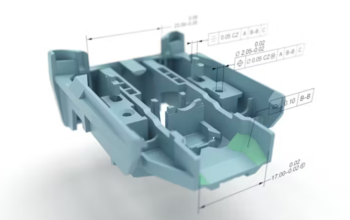

The company found the right overall concept at Mahr Engineered Solutions (MES) with a MarSurf Series 1200 CNC measuring station specially tailored to its needs. It enables fully automatic roughness measurements and contour measurements of internal and external geometries. For this purpose, the measuring station has five automatic axes to position the workpiece and test it fully automatically with maximum flexibility. The workpiece is picked up by means of a clamping ball adapter, which enables any number of different workpieces to be picked up easily and reproducibly for a wide variety of measuring tasks. In addition, the automatic probe arm changer ensures a fully automatic measuring process without user intervention. Furthermore, the measuring station is programmed using the proven MarWin standard interface, which is designed to be intuitive and easy to operate. The measuring station is available for use in the measuring room or directly in production.

- Here you will find further solutions from Mahr for contour and surface metrology.

- View the product portfolio of Mahr Engineered Solutions

- Would you like to realize your own project with us? You can find more information here.