Renishaw, a world leader in measuring and manufacturing systems, now offers an extended range of AGILITY® co-ordinate measuring machines (CMMs). The range of AGILITY CMMs has been designed and made for speed and accuracy, building on Renishaw’s unrivalled reputation for innovation in the most demanding industry sectors. It is optimised for Renishaw’s REVO® 5-axis multi-sensor system and delivers new capability to the shop floor.

Nathan Fielder, Renishaw’s Product Manager for the AGILITY CMM range, explains; “We took the award winning REVO 5-axis multi-sensor system and asked ourselves: how can we turn this into an even better solution to meet the challenging demands of high-end manufacturers? The result is the AGILITY range – CMMs which deliver the advantages of the REVO multi-sensor system where they matter most; close to the point of manufacture. The tried and tested range of AGILITY CMMs now includes machines for the measurement lab, offering high throughput platforms capable of using any one of the seven dedicated REVO sensors.”

The multi-sensor CMMs enable manufacturers to carry out multiple measurement processes and report results on a single device. The full range of REVO sensors is available to AGILITY CMM users, which includes tactile touch-trigger and scanning, surface roughness, temperature, ultrasonic thickness measurement and non-contact probes.

The machine’s structure combines granite and anodised aluminium to provide excellent strength and stability whilst ensuring accurate metrology throughout the measuring volume. Critical elements such as bearing design and placement, the innovative cable track arrangement, and frictionless linear motors, ensure a stable and repeatable platform when the REVO system is scanning at high speeds. Minimal contacting parts prevent friction and thermal instability, whilst also reducing wear and maintenance requirements. The elevated and protected Y-axis drive system minimises the moving structural mass and prevents contamination.

Renishaw’s AGILITY S shop floor CMMs provide a highly accurate and robust solution for inspecting manufactured parts in a production environment where clean air and temperature control cannot be guaranteed. They are available with working volumes ranging from 700 x 900 x 600 mm up to 1600 x 2400 x 1200 mm (X x Y x Z), plus variants with a raised working volume to accommodate pallet loading systems or rotary tables. All shop floor models have elevated Y-axis guideways for further stability and protection from airborne contaminants. The larger S frames feature a dual drive and dual scale Y-axis configuration.

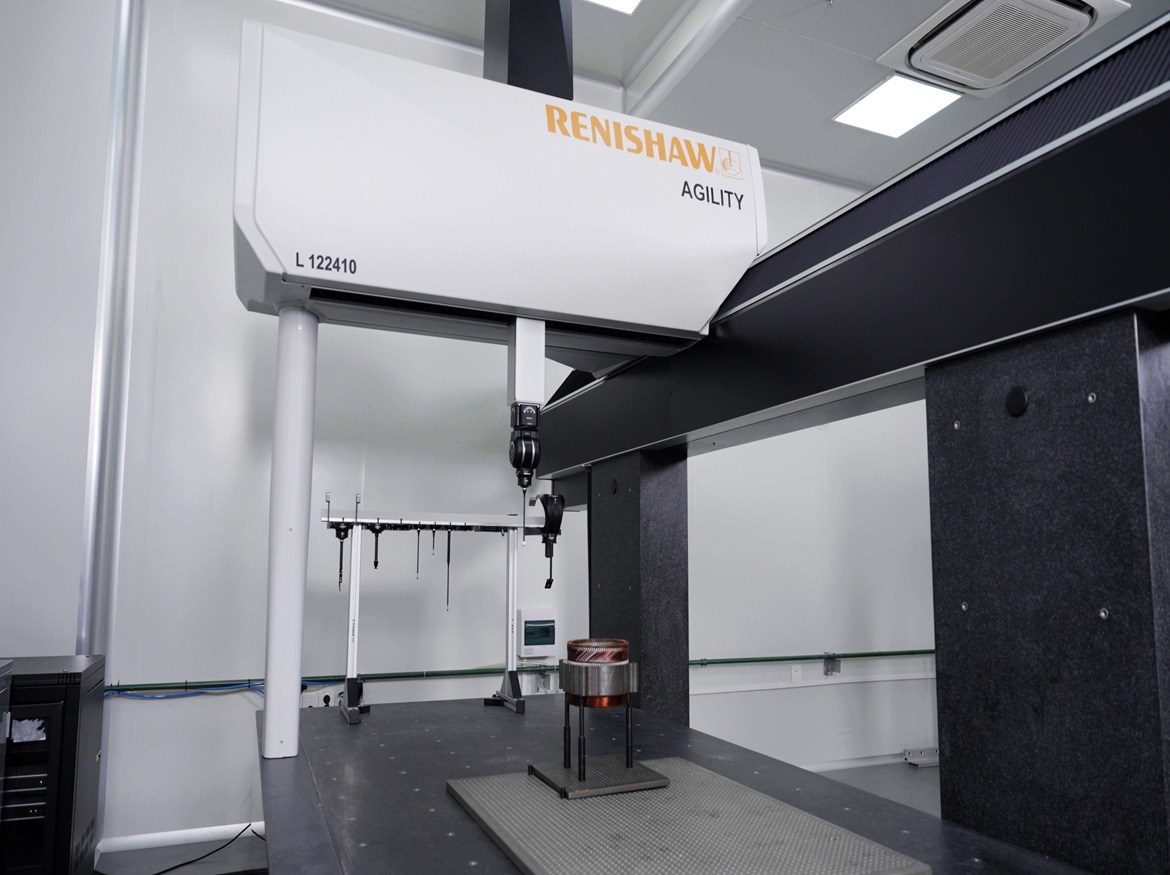

AGILITY L machines, designed for the metrology lab, are specified for a temperature range of 18 °C to 22 °C and provide high-performance, multi-sensor 5-axis measurement in clean rooms. The single-sided raised Y-axis design with an outrigger leg expands accessibility for manual part loading when automation is not required. AGILITY L frames are available with working volumes ranging from 500 x 500 x 500 mm up to 1600 x 3500 x 1200 mm (X x Y x Z).

The AGILITY range of CMMs combines the broad range of technologies and end-to-end manufacturing expertise that have built Renishaw’s reputation for innovation and quality. Leigh Elsworthy, CMM Customer Services Manager, says: “In addition to the machine frame itself, the probing system, encoders, machine controller, linear motors, styli, part fixturing, measurement software, and even the laser-based mapping and verification systems, are designed and made by us. Renishaw has total control of the supply, installation, and maintenance of the CMM throughout its life.” Every machine is error-mapped and certified using Renishaw’s laser calibration systems. Only certified installers will carry out installation and service, with an option for UKAS or A2LA accreditation.

AGILITY CMMs are also compatible with Renishaw Central, a powerful manufacturing data platform which enables reporting and closed-loop process control on the shop floor. Renishaw Central uses measurement data to identify deviations and automatically send correction updates to the appropriate manufacturing machines.

For further information on AGILITY CMMs, visit www.renishaw.com/agility