Why and How 3D Scanners are Suitable for Vehicle Modification?

To meet the demands of rescue operations, rescue teams recognize the importance of fine-tuning the vehicle structure and efficiently integrating equipment systems. In this case, the advantages of the FreeScan Trak Pro2 and FreeScan Combo metrology 3D scanner were demonstrated: both of the two scanners provide high-accuracy measurement, and after acquiring the 3D data of the rescue vehicle, they can easily handle complex modifications and inspections in conjunction with the design and inspection software, ensuring that every modification is fully compliant with the team’s requirements. The FreeScan Trak Pro2 dynamic tracking 3D system is designed for large-scene scanning. It uses dynamic tracking and laser scanning without markers to easily acquire data from the entire rescue vehicle, ensuring the integrity and comprehensiveness of the 3D data.

FreeScan Trak Pro2

With high precision and repeatability, the FreeScan Trak Pro2 allows for fast, accurate inspection of various part types and surfaces without the need for markers. It is the ideal metrology tool for quality control and 3D inspection.

- No Markers Needed

- Exceptional Accuracy

- Wide Measuring Range

Thanks to the lightweight and optimized camera angles, the FreeScan Combo is compact and small enough to work flexibly in tight spaces. It can also accurately capture the details of complex textures, bumps, and holes on vehicle surfaces.

Scanning process and data of FreeScan Combo

FreeScan Combo

The powerful FreeScan Combo packs dual light sources in an ultra-compact shell, measuring just 193x63x53mm. It’s equipped with both blue laser and infrared VCSEL technology and weighs in at only 620g.

- Blue laser & Infrared light

- 4 Scanning modes to cover all types of workpieces

- Lightweight

What Aspects Did 3D Scanners Help?

Based on the high-accuracy 3D data obtained by the 3D scanners, the rescue team made a breakthrough in the fine modification of vehicle structure and the efficient integration of equipment systems.

Reserve space and system optimization

Rescue teams optimize the configuration of the vehicle’s internal space by analyzing the 3D scanning data of the rescue vehicle. This enables the efficient loading and transport of large-scale rescue materials despite the limited personnel. In addition, thanks to the accuracy of the scanning data, the rescue team can identify and solve the potential loading space structure unreasonable problems in the virtual assembly stage, effectively avoiding the modification risk.

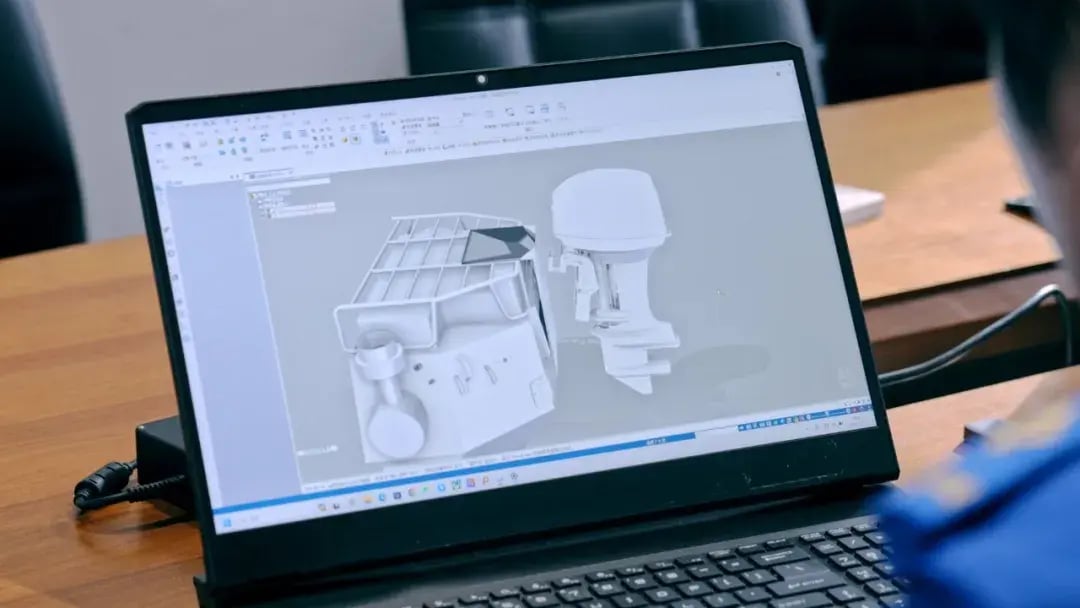

Designing part of the rescue vehicle to be modified in the software based on the scanning data

Modified rescue vehicle

Integration with UAVs

After accurately obtaining the complete 3D data of the rescue vehicle, the rescue team could finely plan the installation position and bracket structure of the UAV airfield on the rescue vehicle. The solid installation of the equipment further enhanced the responsiveness of the on-site rescue.

UAV used by Blue Sky Rescue team

Conclusion

Integrating the FreeScan Trak Pro2 and FreeScan Combo into the Shanghai Blue Sky Rescue Team’s vehicle modification process significantly advances emergency rescue operations.