Since its initial release about 40 years ago, the Audi Sport Quattro road and rally car has captured the attention of several auto fans. It’s even referred to as the “legend of motorsports” by some. Because of this, two businesses with a passion for motorsports decided to reproduce it using 3D scanning and 3D printing.

On the one hand, LCE Performance set the standard thanks to its extensive expertise in engine and vehicle tuning. On the other hand, Downforce Racing contributed its expertise in the production of carbon-brazed parts.

The teams worked together to create an Audi Sport Quattro replica using carbon components and CFD calculations. Their copy appears to be beautiful:

The main challenge of improving the performance of the racing car

The biggest difficulty in this project was managing older elements. Due to the race car’s extensive history, many of its original components are no longer in manufacture.

Even if used parts were accessible, they were expensive to purchase and challenging to remodel. They appear worn out and are 40 years old. I’m very much unable to restore them. LCE Performance’s Steven commented.

These subpar used components were not an option for a company that wanted to concentrate on delivering high-quality, long-lasting parts for its clients.

3D scanning with FreeScan UE Pro for reproducing parts

There are two approaches to using 3D scanning technology to overcome these difficulties. In the first, a new part is made by scanning the old one, while in the second, a race vehicle is scanned and a brand-new design is created.

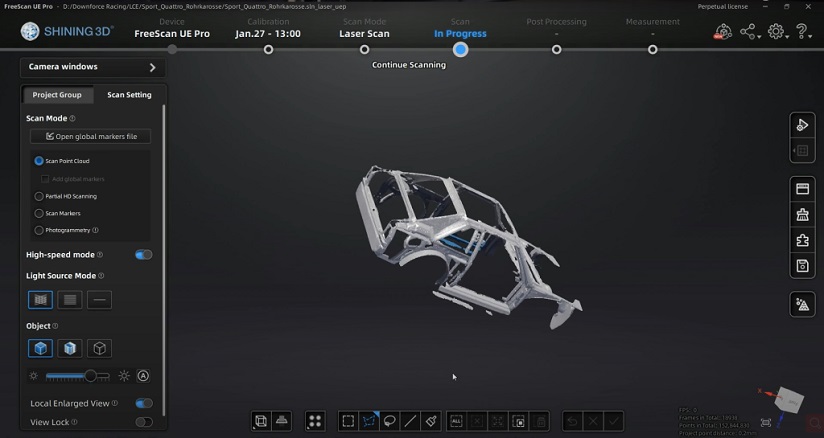

LCE Performance is 3D scanned the complete car’s frame in this instance. With the aid of the 3D Scanning Academy, the team utilised the SHINING 3D FreeScan UE Pro. Before 3D scanning the chassis, they took off the fenders and accessories to make it easier to create a clear 3D model.

They next thoroughly inspected the car’s body. This was done to see if the car’s major geometries were still intact or if an accident had possibly harmed them.

The team was able to easily and swiftly collect high-quality data, even on such a massive object, using the FreeScan UE Pro’s Rapid Scan mode. They also didn’t have to spray the portions made of dark carbon.

3D scanning and 3D modeling for CFD simulations

It was time for Downforce Racing to take over after the 3D scanning process. They produced separate 3D models using the clear, precise 3D data provided by LCE Performance.

In order to enhance car performance, 3D models created by 3D scanners and some reverse engineering were also applied to CFD simulations. A simulation tool called CFD is used to examine and forecast the behavior of gases and fluids in motion. Before the new carbon pieces were produced, the team was able to test and refine the design using CFD models. This gave them the chance to enhance the car’s aerodynamics, lower drag, and boost performance throughout each drive.

The collaboration between LCE Performance and Downforce Racing has been a success, in part because of their skillful application of 3D scanning technology. This demonstrates the crucial function that 3D scanning plays in the world of racing automobiles, especially in overcoming the difficulty of precisely replicating parts and enhancing race car performance.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.