A revolutionary robotic approach is being used by Q5D Technologies and the University of Sheffield Advanced Manufacturing Research Centre (AMRC) in a £1.7 million initiative to further automation in the aerospace sector by adding integrated wire to intricate aircraft components.

By integrating wire into the structures that make up these elements, Project LiveWire, headed by Bristol-based Q5D, aims to automate the production of aeroplane seating components and control systems, thereby lowering costs and producing lighter, higher-quality components.

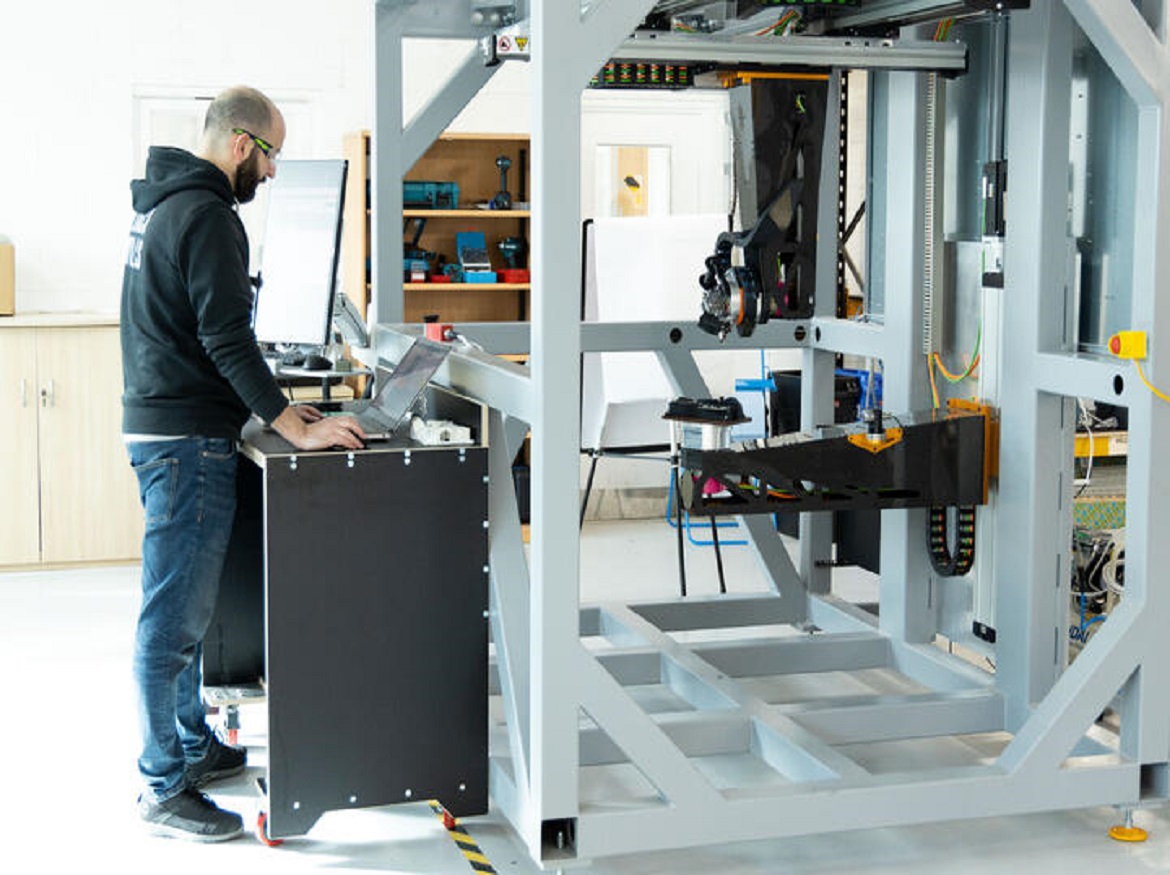

Currently, wiring is done by hand in vehicles, aeroplanes, and many other consumer electrical products, which makes it an expensive and time-consuming operation that is prone to mistakes, malfunctions, and occasionally even fires. In support of this project, Q5D developed a 5-axis robotic tool that makes it easier and more efficient to add wiring to intricately formed components.

The High-Value Manufacturing (HVM) Catapult assigned the AMRC the task of developing integrated validation processes for quality inspection as well as a proof-of-concept solution to calculate the position and rotation of a workpiece in order to allow the robot to fully automate the process of embedding wiring into them for use in the aerospace industry.

“Q5D tasked the AMRC with making sure that the position and rotation angle of the workpiece produced the best possible accuracy while maintaining high repeatability and a quick computational process,” stated Edwin Anarcaya Roca, research engineer at the AMRC.

In order to do this, AMRC engineers ran a variety of tests to determine the hardware and software that would work best and support the business in building a proof-of-concept solution using a stereo vision camera.

As a result of the advantages of automating the robot path with a vision system, Q5D’s robotic technology will have more adaptability to change with changing environments. Productivity will rise when automatic robotic route adjustments are made on-the-fly, reducing the need for manual programming to change the robot tool path.

To automate the wiring examination, Roca continued, “The AMRC also created proof-of-concept computer vision systems. Algorithms that identify flaws including wire breakages, crushed wires, stripped wire insulation, wires escaping from the track, and inadequate track walls are some of these solutions.

A real-time, embedded wire fault detection system that is integrated with the machine itself may be created using the methodologies utilised in these defect detection algorithms. This project examined a potential use route for the aerospace industry, but the concept is applicable to any robotic automation system.

“Working with Q5D Technology, the Livewire project has been a great opportunity to develop innovative computer vision solutions for a really novel system,” said Chris Scraggs, topic lead for automation at the AMRC. We’re eager to receive a Q5D machine for additional testing and are interested in watching how the technology advances.

“Q5D are developing 5-axis robotic manufacturing cells to add wires, components, and printed conductive tracks to complex parts from aerospace to consumer goods,” stated Peter Todd, operations manager at Q5D. AMRC was a natural partner for this project given their standing in the robotics and automation industries.

Our objective is to adopt a CAD/CAM technique to automate the primarily manual processes currently used to build wiring harnesses, which will also open up new potential for product design, save weight, and consume less space.

The project is a partnership between Q5D, the University of Sheffield AMRC, and other businesses, such as OnePLM, M-Solv, and Safran. It is financed by Innovate UK as part of the ATI programme.

Credits: AMRC

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.