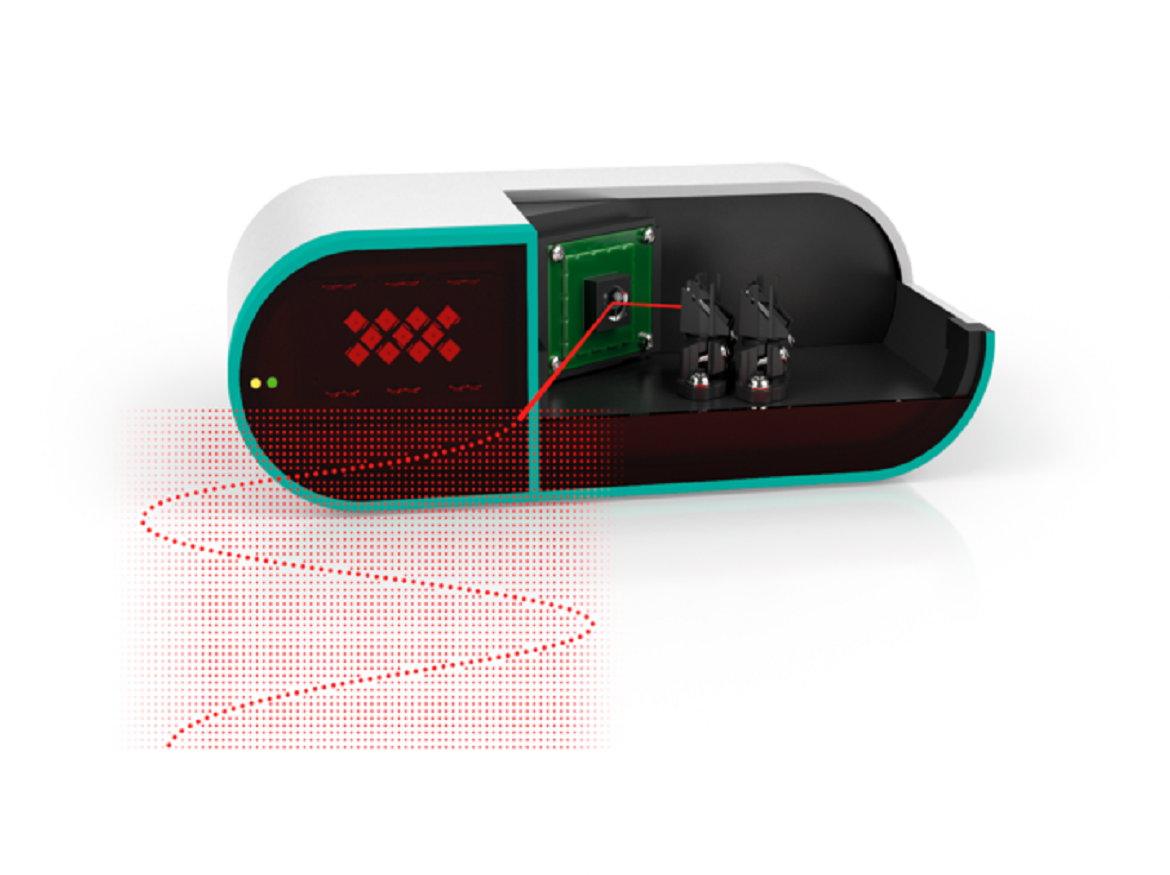

The combination of Pulse Ranging (PRT) and MEMS technologies enables the creation of high-resolution 3D point clouds

To tackle the challenges of the future, from industrial automation to autonomous vehicles to assistance robots, we will require potent 3D sensors capable of quickly and precisely collecting their whole environment. A Pepperl+Fuchs technological advancement that was created in partnership with the Fraunhofer Institute for Silicon Technology ISIT gives the highest levels of precision and performance while yet being very affordable. MEMS technology is coupled for the first time with high-performance telemetry technology. The R3000 3D LiDAR/MEMS detector, which will be unveiled as a product study at the Hanover Motor Show in 2023, is built on the foundation of this combination. To find out more, stop by the booth in Hall 9 at D76!

Combine the advantages of two technologies

Pulse ranging technology (PRT) is the foundation of the 3D measurement. This distance measurement technique, created by Pepperl+Fuchs, can be modified to satisfy a variety of needs. With millimetre precision, it estimates distances from a few centimetres to several hundred metres using more than 250,000 laser pulses that are emitted every second. Effectively removing stray light and other environmental elements. Thus, PRT technology offers quick, precise, and trustworthy measurement results.

In the R3000 product study, Pepperl+Fuchs is fusing PRT technology with a Fraunhofer ISIT micro-electromechanical system for the first time to create the third dimension. A compact, reliable, and cost-effective MEMS mirror is built into the detector. As the piezoelectric element moves, the laser beam is deflected into two axes measuring 40° by 30°. The measurement procedure does not result in the creation of a pixel grid, unlike other 3D detectors. Instead, the R3000 produces ultra-high resolution 3D point clouds with excellent detail by continuously scanning and using a tiny light source.

Intuitive operation thanks to intelligent user guidance

The R3000 has extra features that make it easier for people to communicate with machines. The detector produces a 3D point cloud in addition to an intensity image that may be used to visualise the scene and assist operation and programming. Additionally, a visible laser beam can be used to display each measurement point. The R3000 can be accurately positioned and modified without the use of extra equipment thanks to the synchronous laser projector, making commissioning simple. Additionally, this feature enables the user to engage with a service robot, for instance.

Powerful 3D measurement for the automation of tomorrow

The R3000 LiDAR/MEMS detector ushers in a revolution in the approach to challenging automation tasks thanks to this ground-breaking technology. Access to precise 3D photographs of new locations is crucial for the next generation of autonomous vehicles, which range from driverless industrial transport systems to automated patient transport in retirement and care homes.

These intricate and dynamic sceneries can be captured in great detail and in real-time by combining PRT and MEMS technology. This makes it possible to build an extensive database for further evaluations using artificial intelligence (AI) techniques. Compact and affordable, the R3000 provides high-precision 3D measurements for a variety of applications. When used in conjunction with cutting-edge algorithms, the detector will hasten the growth of the autonomous car and service robots industries, not just for use in factories, hospitals, or nursing homes but for many facets of daily life.

Assets

- Innovative Product Study: Compact and Cost-Effective R3000 LiDAR/MEMS Detector Enables Detailed 3D Measurement by Combining Two High-Performance Technologies

- Pulse Ranging Technology (PRT) for reliable, accurate and scalable distance measurements

- Integrated MEMS mirror for continuous scanning and ultra-high resolution 3D point clouds

- Detailed capture of dynamic and complex scenes in real-time for any type of application, from automated guided vehicles to service robots

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.