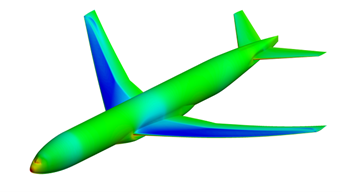

In order to assess and research the effectiveness of its aircraft aerodynamics analysis, Ryoyu Systems Co., Ltd. has implemented scFLOW, one of the Cradle CFD computational fluid dynamics software products from the Hexagon Manufacturing Intelligence division.

In order to effectively address issues with aerodynamics in automotive and aerospace, supersonic flows, the performance of rotating equipment like fans and pumps, thermal design of electronic equipment, multiphase flow phenomena, propeller cavitation in ships, etc., scFLOW can accurately represent complex geometries using unstructured meshes.

Ryoyu Systems views analysis and design engineering as an essential activity that directly ties to “manufacturing” with a substantial impact on the competitiveness of goods in the engineering business, where technological innovation occurs at a quick rate. Accordingly, the business has long provided analysis solution services, including analyses focusing on the aerodynamics/structure of aircraft, spacecraft, engines, and mechanical equipment, as well as crash/shock analyses of automobiles, CAD-based design services, and the development of systems for design efficiency.

In order to conduct this evaluation research, Ryoyu Systems presented scFLOW on the basis of the product’s undeniable superiority, which the business had already established through more than 30 years of continuous usage of simulation software from MSC Software, a Hexagon group company.

Ryoyu Systems has been employing general-purpose software to perform partial and complete aerodynamic studies of the flow field around an aircraft for some time. In order to reduce expensive and time-consuming testing, the company has recently sought to undertake aerodynamic analysis for more complicated airframe geometry more precisely than with standard software. Ryoyu Systems introduced scFLOW with the intention of assessing the effectiveness and performance of the system.

Multidisciplinary simulation solutions are also offered by Hexagon. In airplane applications, for instance, there is typically not much structural deformation; yet, depending on the circumstances, serious problems with strength or heat may occur. The findings of the scFLOW study can be used for these issues to do thermal stress analysis or structural analysis using MSC Nastran, a program for structural analysis. The outcomes of the structural analysis enable a two-way coupled analysis to be performed by scFLOW. By carrying out such assessments that in the past have had detrimental effects on efficiency, we anticipate being able to continuously enhance our solutions. Using Adams, MBD analysis tools, and scFLOW, we are also considering the feasibility of a fluid-MBD (multi-body dynamics) coupled study.

“In this evaluation study, it took a lot of effort to generate a more detailed mesh for a highly accurate analysis,” said Mr. Jun Ogino, Director, Executive Vice President, and General Manager of Ryoyu Systems Co., Ltd.’s Aerospace Engineering Solution Division. As a result of this experience, we anticipate that scFLOW will include a function that makes it simpler to generate mesh for analyses that require meshes produced by other products while also supporting those analyses.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.