In Japan, where there is a shortage of engineers, many businesses are now stepping up their attempts to change the way they operate, with the manufacturing sector having the greatest need to solve this problem. In addition, many businesses are struggling to transfer knowledge to younger employees as the baby boomer generation of seasoned engineers retires, and an increasing number of businesses are working to increase the effectiveness of measurement work at production sites, which had previously been ineffective.

In the past, measuring curved and free-form styrene foam shapes required a great deal of time-consuming manual labour with callipers. The comparison of the measurement results with the original CAD data might take several man-hours and frequently relies on the tacit knowledge of the seasoned staff. Additionally, the production line must be briefly paused in order to assure measurement accuracy, which occasionally results in ineffective operations.

The company Sakai Model Making Corporation produces a range of models, including casting models for flans, V-process, automatic moulding machines, moulds, resin moulds, and full-mould, by utilising the expertise and experience that it has amassed over the course of more than 50 years in the industry. The company’s business strategy entails taking orders directly from makers of machine tools and collaborating with producers of metal castings while being flexible enough to alter the size, form, and quantity of models produced on an individual basis in response to client needs. The identical measuring issue existed at Sakai Model Making.

In addition to these measuring problems, Sakai Model Making Corp. had to deal with the obstacles of dealing with an ageing and shrinking workforce, passing on skills, developing young workers, and changing work styles. We spoke with the primary project participants about Sakai Model Making Corp.’s 3D measuring initiatives.

Urgent needs to improve dimensional inspections, which are too generic and inefficient.

Dimensional inspection is necessary for quality assurance prior to exporting a model. Due to the fact that many of the models are castings, have several curved surfaces, and have intricate designs, the measurement was traditionally done by hand, which is a very challenging operation. Additionally, because the majority of models are made of brittle, soft styrene foam, extra care must be given when measuring them. When evaluating dimensions, each location was meticulously probed with a ruler or a convex gauge, and for complex curved surfaces, a special gauge may have been built just for the job.

Castings can range in size from the size of a hand to 10 metres. It goes without saying that the supply of a high-quality and high-precision model is necessary because it is the component that supports the foundation.

It is not practical to manually measure all of a model’s intricate dimensions, despite the dimensional accuracy of between 0.5 mm and 1 mm that is required for model production. In order to properly analyse the measurement points and release the moulds or finish the castings, it was required to ascertain which dimensions were crucial. Additionally, during the pre-shipment inspection, I was the only one who could make the ultimate judgement.

“We wouldn’t have been able to keep our client’s trust in the long run if we had stuck with the old system. We made the decision to switch to a digital strategy to get out of this predicament and enhance our operations,” stated Mr Sakai.

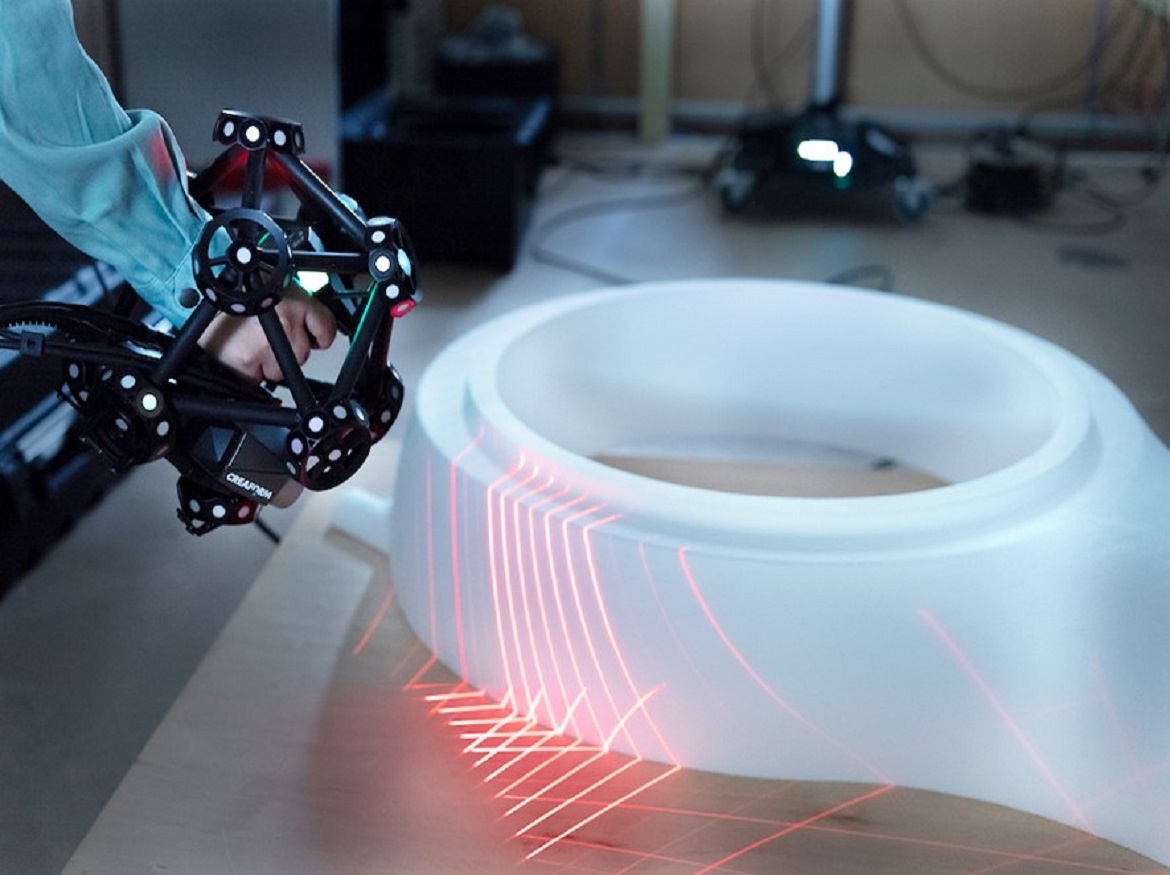

MetraSCAN 3D was chosen for its overwhelmingly fast measurement speed and compactness

Sakai Model Making Corp. focused on 3D scanners as a way to enhance the measurement process since they can simultaneously scan real curved surfaces and complex objects with a laser and digitise them as 3D data. Mr Isonuma took the initiative and started contrasting the goods.

The measuring speed was the main issue with all the 3D scanners we were investigating at the time, according to Isonuma. We found it unworkable that it took one product eight hours to measure alone.

The models from Sakai Model Making Corp., many of which were also huge and contained a significant number of measurement points, were non-starters due to the slow measuring speed. Furthermore, the factory’s limited space would have been overwhelmed by a huge measuring machine due to the factory’s crowded arrangement of processing machinery.

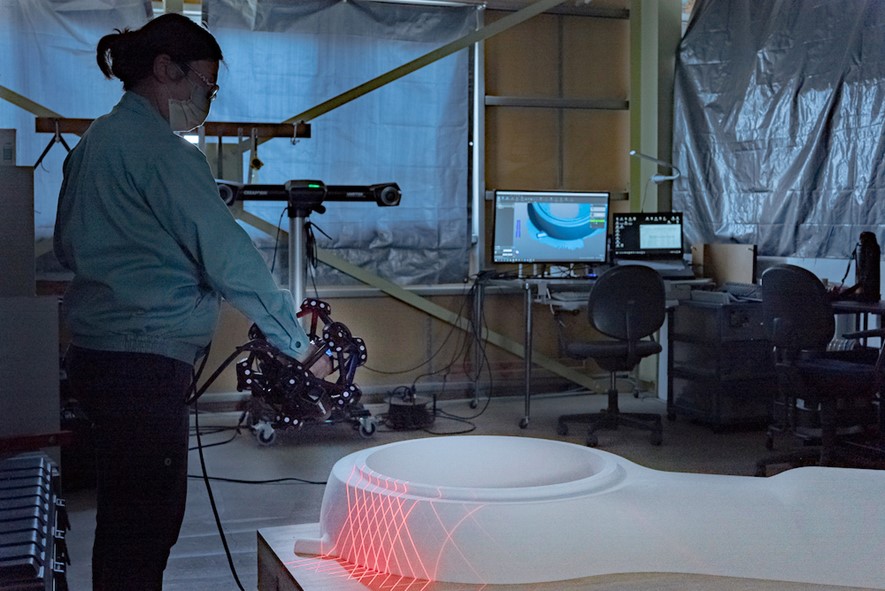

Compactness is essential if you want to make 3D measurements accessible to everyone, regardless of experience. Additionally, fast measurement is necessary to meet client demands. We found that a casting manufacturer with whom we do business was utilising a handheld MetraSCAN 3D with exactly these qualities while we were searching for a 3D scanner that matched these specifications, so we contacted the company right away. When we used the MetraSCAN 3D, we discovered that the scanning speed was incredibly quick and the 3D data could be shown on the PC screen in real-time as the measurement was taking place. This scanner was ultimately chosen since it was the only one that satisfied all the criteria.

The ability of the MetraSCAN 3D to measure both large and tiny items without the need to later recombine and realign data is another benefit. Additionally, even if there are dozens of things to measure, measurements can be carried out one after another because targets are not required to be attached. This is a special capability of the C-Track, which was created for automated self-positioning systems that can quickly and accurately measure the 3D dimensions of massive objects.

Standardization and simplification of measurement work dramatically improve work efficiency

The Sakai Model Making Corp. system administrator immediately saw improvements in the measuring procedures after deploying MetraSCAN 3D.

With just a brief explanation of how the MetraSCAN 3D works, anyone may learn calibration and measuring techniques. Naturally, it takes time to learn how to alter data and produce data for inspection, but new hires picked up the measuring work on their first day on the job.

The measuring process alone used to take a day and a half when I used to manually measure the measurements of medium-sized models, but MetraSCAN 3D has cut the time in half. The final evaluation is still made by me, but since I am no longer responsible for measuring and reporting, I no longer need to set aside a week for pre-shipment inspections. The time saved can now be used productively to create quotes,” he claims.

The processing data that Mr Isonuma now produces using 3D data is reviewed by the system administrator before being changed into machining data. Following a measurement with the MetraSCAN 3D of the assembled items, the design data and the 3D data received from the measurement are superimposed and compared. A quality assurance programme for clients after delivery has also been built because the measurement findings are kept as 3D data. The business process itself is being digitised; it’s not merely an issue of increasing inspection efficiency.

Accelerating business efficiency with 3D data to begin a new era

In order to create a setting where operations can be carried out mostly by younger workers without relying on skilled staff, Sakai Model Making Corp. wants to further automate its work system, including pre-shipment inspections. The business also intends to use MetraSCAN 3D and 3D data not just for inspection but also for manufacturing. In order to further increase operational efficiency, the company also wants to deploy 3D printers as part of this strategy.

The purchase of wood and other resources has become uncertain due to the recent Corona situation and geopolitical concerns, and costs have soared. In addition, if the business does not address the SDGs, it will lose credibility. We will seek to further increase efficiency by utilising 3D data to address these social challenges, said Mr Sakai, outlining his future goals.

Credits: Creaform3d

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.