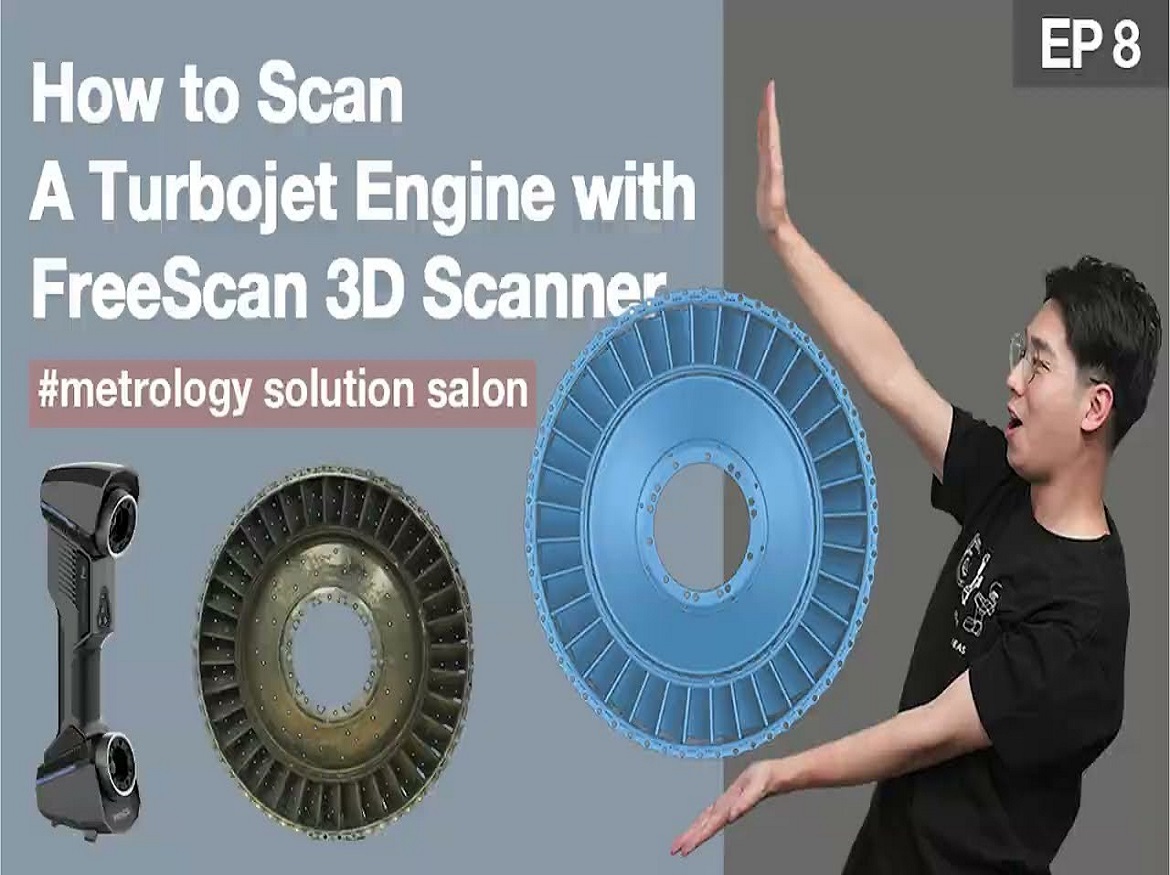

The key component of the airplane is its turbo engines. Through use, it will sustain varied degrees of wear, and a 3D scanner is a great tool for examining this wear.

The turbojet engine’s multiple blades are plain to observe. Traditional measurement techniques are difficult to use rapidly because these blades have deep regions and irregularly curved surfaces. The turbojet engine was also quite heavy and difficult to handle, making the measurement more challenging.

In this tutorial, we’ll use the Shining 3D FreeScan UE Pro laser handheld 3D scanner to quickly and easily scan a turbojet engine.

Step 1 – Quick Access to Global Data

With its 840g weight and ergonomic design, the FreeScan UE Pro makes scanning quick and easy. To swiftly gather the fundamental information about the turbojet engine, we first employed the multiple lines scan mode. This mode features a wider FOV and 26 cross-laser lines. Moreover, FreeScan UE Pro’s precision is up to 0.02mm, with minor errors that fully satisfy industrial inspection requirements.

*Tips: After the initial scan is finished, you can speed up the optimization and point cloud production processes by creating a cutting plane.

Step 2 – Data Acquisition of Deep Areas

A supplemental scan using the single line scan mode to provide more thorough data is particularly ideal for harder-to-scan locations such deep holes and pocket areas. We can see that certain deep holes or pocket areas have additional data after the scan is complete.

Step 3 – Data Processing in FreeScan Software

The dazzling 3D FreeScan program allows for the immediate processing of scanned data. We can obtain the data we require and eliminate the data we do not, thanks to the area and related field function. In order to improve alignment outcomes and ensure data quality, the optimization and point cloud creation function may de-duplicate and denoise points of the scanned data as well as reduce the likelihood of misalignment. Also, the entire data set may be imported for processing into popular 3D inspection and design programs like Geomagic Control X and Geomagic Design X. We finally combine with one click to get all the info.

FreeScan UE Pro also offers a fine scan mode with 5 parallel laser lines, which allows one to scan the fine features of an object and properly recover its details.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.