Measuring in the Production Environment

This content was originally written and published by the Wenzel Group’s team on their website. Reproduced here from https://www.wenzel-group.com/en/products/3d-shop-floor-kmg-wenzel-sf-55/

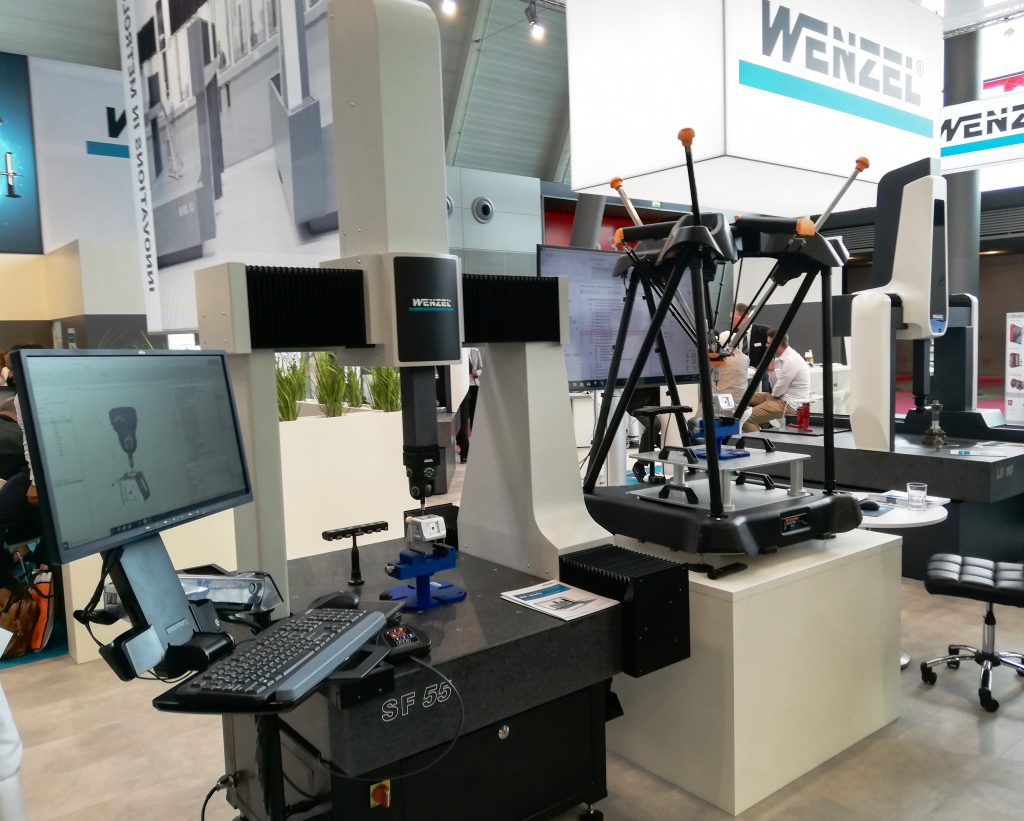

The SF 55 3D Shop Floor CMM is a CNC bridge measuring device for use in a production environment and can be equipped with both tactile and optical sensors. The corrosion-free guides of the machine are made of granite and hand lapped with high precision. The guideways are completely covered and protected against contamination.

The controller and PC are integrated into the machine for a minimum footprint. The space requirement is low with an excellent price-performance ratio. The SF 55 has passive vibration damping and can optionally be equipped with active vibration isolation.

High traversing speeds and accelerations ensure a high measuring throughput. As an “Equator-Calibrator“, the SF 55 is the ideal measuring machine when packaged with the Equator from Renishaw, which carries out comparative test measurements on the basis of a master data set.

Features

- Cost-effective entry into coordinate measuring technology due to excellent price-performance ratio

- Flexible and universally applicable in the workshop and in production

- High measuring throughput with scanning measuring heads

- High accuracy over a wide temperature range due to the use of granite in all axes

- Compact design with a small footprint

Fields of Applications

The SF 55 can be used universally. Serial and individual prismatic and free-form workpieces can be measured with the coordinate measuring machine in a production environment, for incoming goods, and for classic quality assurance.

Benefits

- High flexibility

Bellows covers to protect against contamination | Data compatibility with other WENZEL systems | Height-adjustable operating arm - High mechanical precision

Granite base | Hand-lapped base plate (DIN 876/0) | Air bearing guide elements in all axes - Low operating costs

Low air consumption | Renishaw sensors | Reliable and inexpensive spare parts - Versatile sensor options

Swappable sensor systems | 3-axis scanning | Optical sensor technology - Suitable for automation and integration into the line

WENZEL-Automation-Interface (WAI) | Good accessibility | WM | SYS Analyzer

To know more, please check Wenzel Group.