In the industrial sector, a procedure known as “reverse engineering” has gained popularity. It entails measuring and evaluating a physical object without using the original blueprints or documentation, reconstructing the geometric model, and then making a copy of the product using a CNC machine tool or a 3D printer. In this post, we’ll concentrate on how to effectively use Geomagic Design X, a software programme that is frequently used for reverse engineering.

Obtain 3D Data

Utilising a 3D scanner to collect the object’s 3D data is a prerequisite for reverse engineering. In this instance, we made use of the portable, metrology-grade SHINING 3D FreeScan UE Pro laser 3D scanner. The cross laser lines scanning mode provided a clear presentation of the object’s 3D data. After processing, the data is transformed into an STL file.

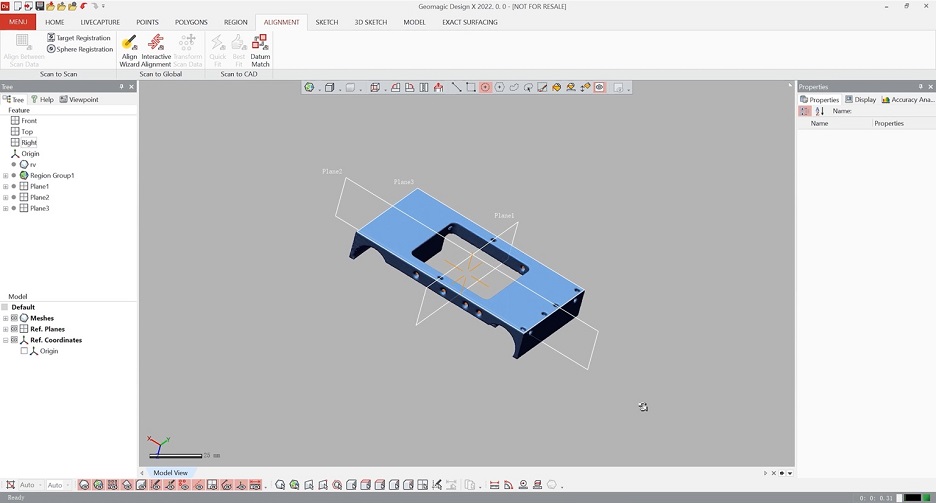

Alignment

The scanned data must then be imported into Design X as the next stage. The “Auto Segment” function in Design X may divide the data into various coloured geometric sections based on characteristics and curvature. Planes, curves, and points are examples of reference features that can be made using these regions. In this instance, we use the “Interactive Alignment” function to build planes using the “plane” function.

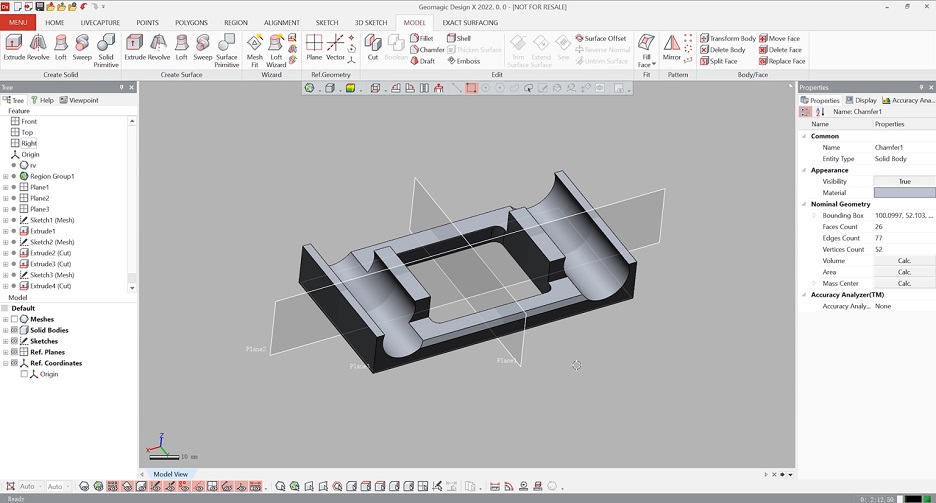

Modelling

The modelling procedure can start as soon as the data are in alignment. The objective is to build a model that resembles the scanned model and add or remove data to build features. The cross-section’s contour is sketched using the “mesh sketch” feature. The scanned data can be hidden in this phase to make the contour more visible by pressing Ctrl+1. Following this outline, we next use the “line” and “perimeter circle” functions to make the sketch, then the “trim” function to remove some extraneous data. Finally, the “extrude” function is used to construct the solid body.

Geomagic Design X is a crucial tool for reverse engineering, to sum up. The benefits and features of the programme increase the effectiveness and precision of the reverse engineering process. Users of Design X can produce 3D models that faithfully depict the actual product, improving product design and development.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.