Scanning spray supports reverse engineering processes

If individual parts are no longer available, then they can be recreated by means of reverse engineering – frequently via additive manufacturing. Owing to its rapid nature and high precision, additive manufacturing is becoming more and more important. For this purpose, components with complex shapes are captured using a 3D scan, which converts the data into a CAD model and sends it directly to the 3D printer.

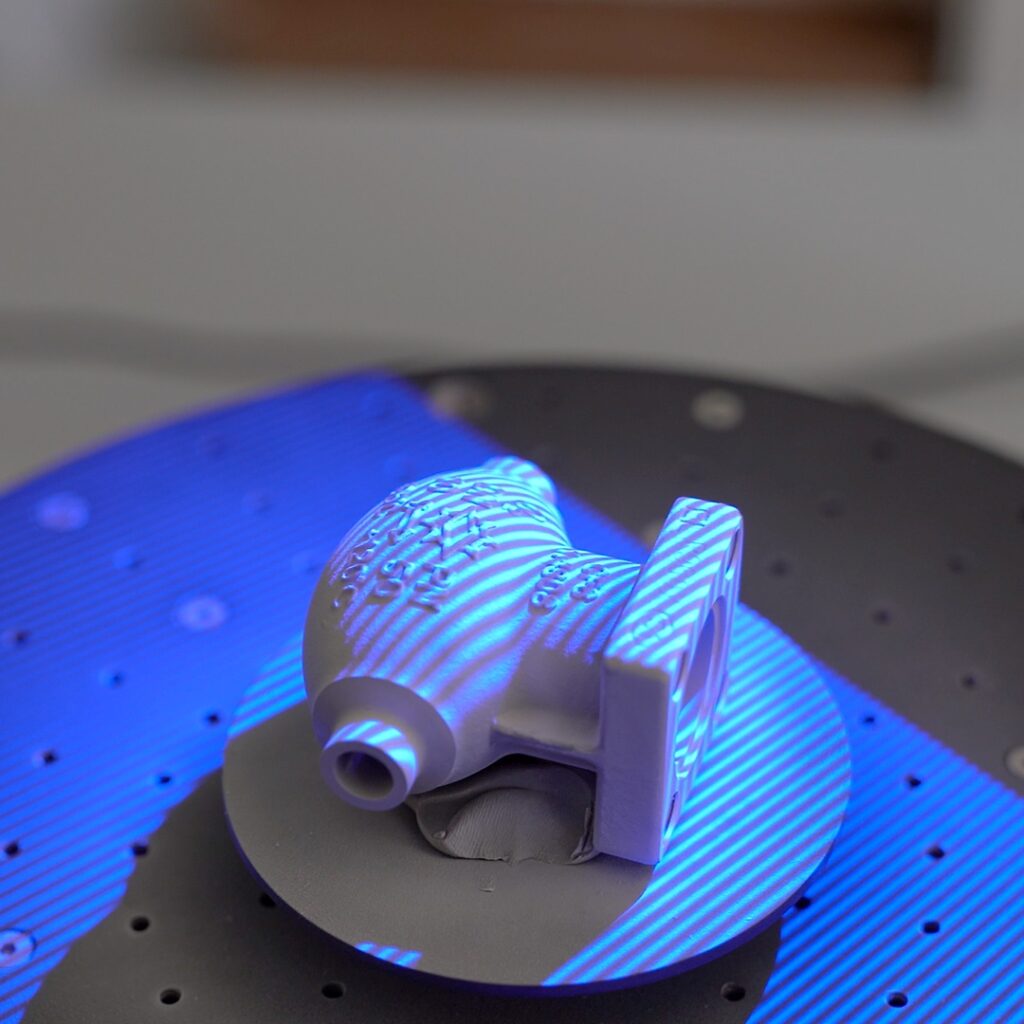

If the parts to be reproduced are shiny, reflective or very dark, they are very difficult for the scanner to recognise. For this reason, they are sprayed with a scanning spray prior to the scan.

The scanning sprays from AESUB form a fine, homogeneous layer on the surface of the workpiece.

The layer is touch-dry and also allows reference points to be applied. A further advantage is that the AESUB scanning sprays sublimate automatically, which means no cleaning of the parts or of the scanning environment is required. AESUB scanning sprays are free from pigments that are harmful to health. They do not contain titanium dioxide.

Photos: AESUB