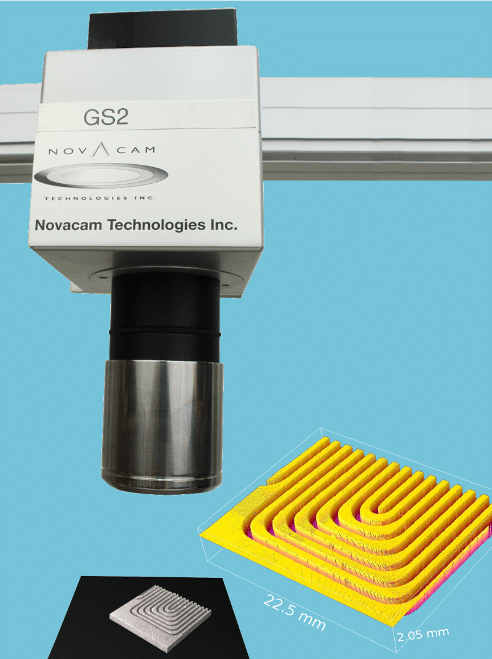

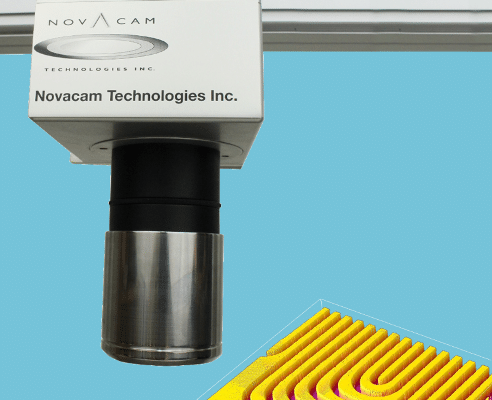

For high-precision 3D metrology

This content was originally written and published by the Novacam team on their website. Reproduced here from this link.

SurfaceInspect is a modular, non-contact 3D metrology system that:

- Acquires micron-resolution measurements of surfaces made of: metal, plastic, glass, ceramic, silicon, polymers, adhesive, composites, liquids, biological tissues, etc.

- Enables fully configurable automated inspection

- Supports user-defined specifications for geometric dimensioning and tolerancing (GD&T), roughness, waviness, etc.

- Supports detection of defects such as burrs, scratches, porosities, etc.

- Measures thickness of semi-transparent materials, including polymers and biological samples/tissue.

The SurfaceInspect galvo scanner acquires surfaces in a raster fashion. Standard fields of view (FOV) go up to 85 x 85 mm. Larger samples are acquired by displacing the galvo scanner and/or samples using linear stages.

Video

SurfaceInspect Overview

Overview of features and benefits

Measurements

- Optical, non-contact, non-destructive

- High speed: Up to 100,000 3D point measurements per second

- 2D and 3D topography of surfaces, including surfaces with high-aspect-ratio features

- Micron-precision axial resolution and excellent sensitivity and measurement repeatability

- Volume loss calculation, wear analysis

Imaging options

- Surface profiles

- Cross-sections (B-scans, C-scans) of semi-transparent materials (infrared-transparent materials)

- Height and light intensity images

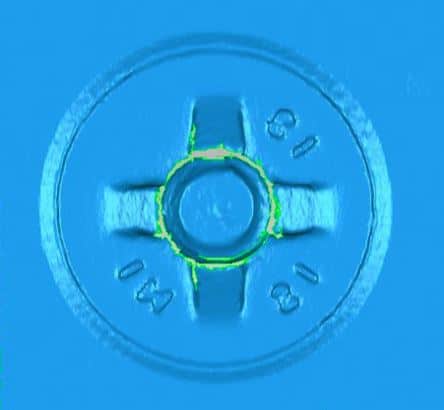

- Deviation maps

- Volumetric images

Benefits

- Easily integrated into lab, shop, or fully-automated industrial inspection setups

Modular and customizable to your criteria - Reduces inspection cycle time: the non-contact optical scanner (or probe, depending on the setup) obtains up to 100,000 measurements per second. Each measurement represents a 3D topographic point.

- Flexible options for evaluating inspected parts: measured features can be compared to CAD drawings or to a set of user-defined GD&T callouts

- Simple scan definition and execution: The scanning sequence is defined once by teaching the system with a joystick. The scanning sequence can later be executed with the push of a button.

- Time-saving automated reporting: Following a scan, go-no-go reports can be produced and results logged in industry-standard formats

- Adaptable to harsh environments

- No consumables are needed: The optical galvo scanner does not come in contact with the measured surface and therefore does not wear out like contact probes.

SurfaceInspect Metrology Applications

3D metrology and imaging of bores for industry and R&D

- Quality control

- Automated 3D production inspection, geometric dimensioning, and tolerancing (GD&T)

- Statistical process control (SPC)

- Research and development (R&D) inspection

- Reverse engineering and part-to-CAD

- Maintenance, repair, and operations (MRO)

- Profilometry in harsh environments

Typical measurements

- Full geometry

- GD&T parameters such as position, profile, straightness, flatness, waviness, etc.

- Roughness: linear or area roughness

- Deviation from the CAD model

- High-aspect-ratio features: teeth, undercuts, steps, grooves, splines, threads, channels, sharp edges

- Volume loss: surface wear or other damage

- Defect detection and characterization: corrosion, pitting, cracking, denting, scratching, porosity

- The thickness of the semi-transparent coating, polymers, and biological samples: single-layer or multilayer films

Examples of inspection applications

SurfaceInspect is a versatile system, delivering 3D metrology across multiple industries – both in high-volume production and in research labs. A few examples of applications:

- Dimensions and surface finish of parts made by machining, casting, injection molding, 3D printing, additive manufacturing, welding, brazing, soldering

- Dimensions and thickness of extruded materials – plastics, ceramics, glass – during or after extrusion. Tubing, sheeting, fibers, etc.

- Continuous casting

- Tool maintenance, edge inspection – sharp edges, chamfered edges, bevel edges, filleted edges, miter edges, burr detection

- Protective film thickness in the aviation and automotive industries, on consumer products

- Multilayer thickness measurements in the cellphone industry

- Optical: etching and deposition thickness on waveguides

- Semi-conductors: coating on MEMS devices, hybrid circuits, fuel, and solar cells; wafer topography, thickness, flatness, defect detection; inspection of thick film photo-resist coating on electronic wafers

- Ophthalmology: inspection of regular or intraocular contact lenses

- Bio-medical: tissue thickness; GD&T and surface finish of orthopedic, ocular, dental, and hearing aid implants; coatings that protect devices from corrosion or patients from complications

- Metallurgy: forging, metal deposition in vacuum deposition chambers

- Others: conformal coating, protective tool coating, vacuum chamber coating

To know more, please check Novacam.