A major inactive zinc mine survey with the Elios 3 proved to have successful results and empowered surveys of old workings.

BENEFITS IN A NUTSHELL

| Safety

Data collected with the Elios 3 would inform operators about the risk of subsidence, any unintended access, and help identify harmful gases. |

Efficiency The Elios 3 was able to unlock new data in just 15 hours of flight, informing the team about the condition of the old workings. |

| Accuracy

Using the Elios 3 for surveys in this old working gave the team an accurate insight into the condition of the world workings and what, if any, work was required. |

Access The Elios 3 replaced an old drone surveying system that required 3×3 metersof space to move – the Elios 3 needs just 60x60cm! |

Mines around the world vary in size, material, and age. The older a mine gets, the more it can be a challenge to manage. Some of the oldest mines in use were already being excavated in the 1800s. Today, as mining operations continue, the challenge of knowing where old tunnels are and their condition presents a potential risk to operations. The “old workings” need to be monitored and potentially sealed to ensure the safety and efficiency of the modern mine.

What are the risks of old workings in mines?

Old workings of mines can be hazardous, whether as part of a disused site or active mine. An old working could be filled with abandoned equipment, or not be structurally sound, presenting a subsidence or collapse hazard. In addition, there can be gas, water, or even harmful substances in the space. The old working may also have no existing or up-to-date records of its condition or layout, presenting a hazard. If new excavations occur, it can be a problem if you accidentally enter an old workings tunnel due to not knowing it was there.

The expanse of a mine underground is a complete mystery from the surface

The expanse of a mine underground is a complete mystery from the surface

Operators typically will approach old workings with 3 aims: to prevent subsidence and unintended access, to deal with any dangerous substances, and to ensure that whatever material or equipment remains in the space is intentional and secured.

Using drone surveys in a mine

The Empire State Mine is owned by Titan Mining, and is located in upstate New York. It is a huge base metal mine that produces high quality zinc ore. The mine is quite old, with zinc mining in the area dating back to the 1920s. Some of the infrastructure there has been in use for decades, and the shaft goes to a depth of 2300 feet at a 40 degree angle.

Surveyors at the Empire State Mine using the Elios 3 as they navigate underground tunnels

Surveyors at the Empire State Mine using the Elios 3 as they navigate underground tunnels

The Elios 3 has been in use at the site with expert pilot Kirk Farrell, who is a technical services manager. He has been using the Elios 3 for mapping 1930s era old workings. The Elios drone replaced a previous cavity monitoring system and other drones on the market that would not work because they needed larger spaces to operate, requiring a 9×9 foot space to move around (3×3 meters). With the Elios 3’s much smaller dimensions of 50×50 cm, it was an ideal solution for close-up analysis of the historic workings as well as broader mapping capabilities. It can also operate without a GPS connection, which is vital for underground mapping projects.

Mapping old workings around a shaft

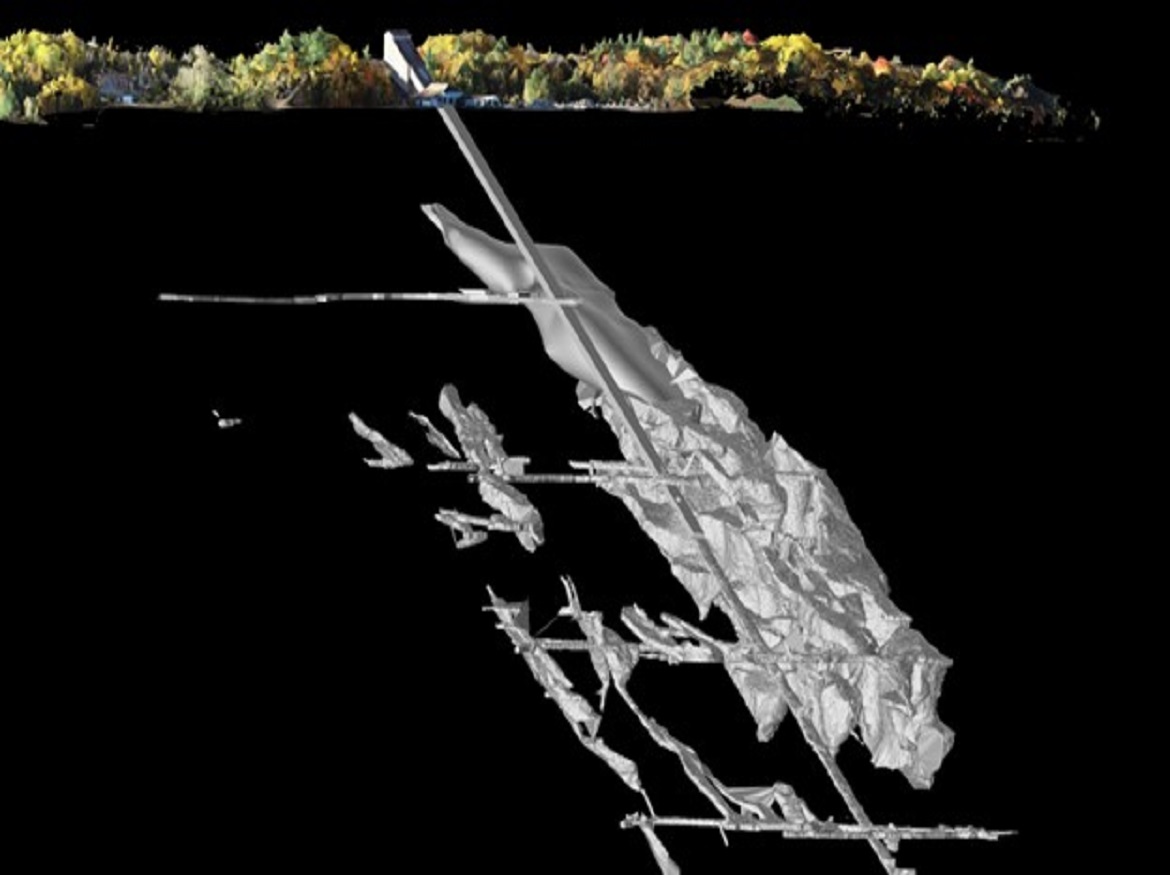

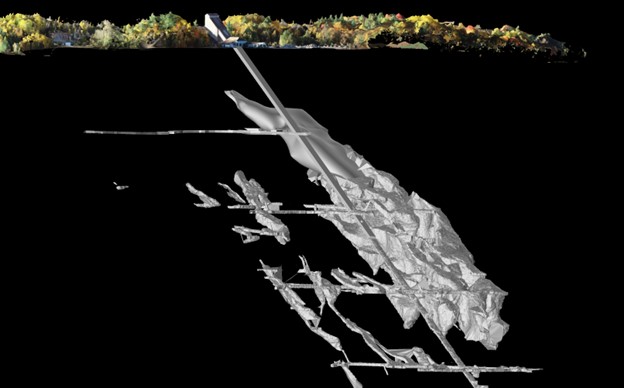

The team at Titan Mining wanted to have an up-to-date visualization of the shaft as well as the connecting network of the mine so they could update their records as well as see a comparison to the surface-level activity. This project needed to provide a thorough understanding of the mine and its layout in its entirety. Some 2D maps and AutoCAD visualizations existed, but there was no single map acting as a source of truth.

Kirk and his team brought in the Elios 3 to map this area. They mapped the entirety of the inactive mine (historic old workings). Some of the tunnels they flew through were just 1.2 meters in diameter, and would not have been an option for the old system to access – however the Elios 3 was able to move through these locations with ease. It provided safe access while inspectors did not have to unnecessarily enter confined spaces or small tunnels.

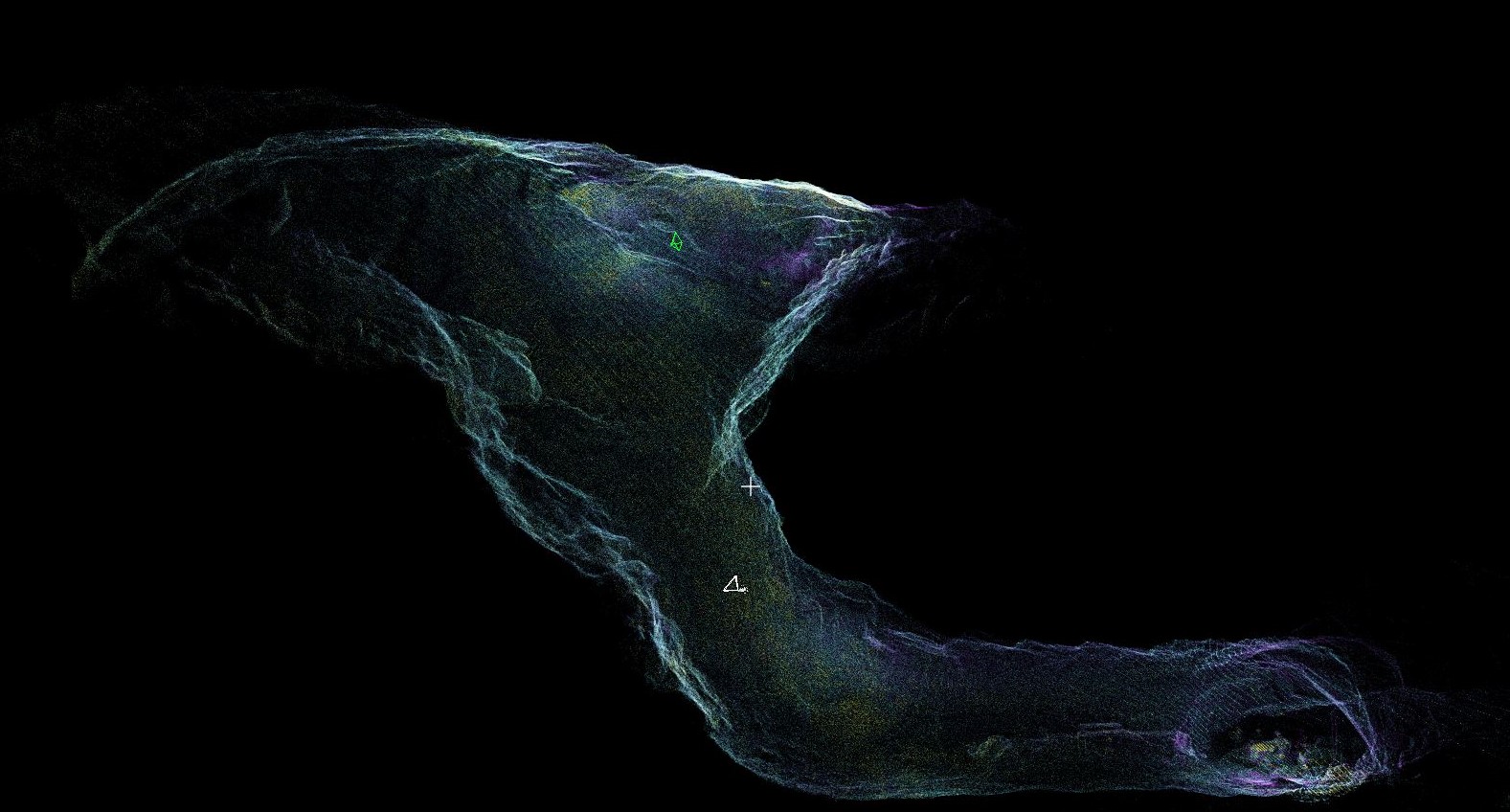

The intricate map of tunnels created with the help of the Elios 3’s data is informing mine management

Using the Elios 3, Kirk and his team analyzed both visual and LiDAR data. They found that the tunnels had almost no degradation, which is a testament to rock quality considering they had been open for almost 100 years.

Through this project, Kirk and his team unlocked a huge amount of knowledge that was previously unavailable. They have also realized they have the ideal solution for accessing and mapping old workings in greater detail. There is a chance that results from the Elios 3 will be used to identify new areas that could be mined for ore.

Results of an underground mine survey with a drone

Kirk and his team used the results from the Elios 3 as well as overground mapping to create a comprehensive 3D model of both the underground and aboveground areas. With just 15 hours of flying they uncovered a huge amount of information that had never been available before.

The Elios 3’s LiDAR point clouds are helping digitize mines in a way that is “a game changer”

“The drone is an absolute game changer for anyone in the underground mining industry and I think it’s incredible. No one was in harm’s way while we got these maps, and we have more detail and data than ever before.” – Kirk Farrell, Technical Services Manager, Empire State Mines

The Elios 3 also provided insight into previous workings in the mine, which is helping the current management team plan future operations and management of the old workings. The drone has helped keep not only the surveying team safe, but streamline safer mapping in the future.

Credits: Flyability