What can fans anticipate from Taylor Hobson at the 2023 Paris Air Show? In order to help you with your quality assurance, their specialists will be providing information on the most recent solutions, such as:

- Fully Automated Stack Alignment Measurement for Precision Assemblies Including Jet Engine modules, Rocket Engine Turbopumps, and many more…

- Powerful TALYStack Optimization Software

- Reduced measurement times – Increased throughput

Most importantly, our systems can be customized to meet your unique requirements. Stop by our booth to challenge our experts!

Make sure you visit Booth #C16 (Hall 3)

Commercial Or Defense – Air, Power, And Marine Applications

Our AEROStack Systems are ideal whether you are new to stack optimization or you have been taking advantage of the principle for many years…

Already relied upon by global engine programs for assembly, Taylor Hobson is capable of measuring individual rotors and complete assemblies whether it’s OEM or aftermarket.

By utilizing axial and radial measurements on individual components, the best assembly build configurations can be calculated to meet optimal performance for your products.

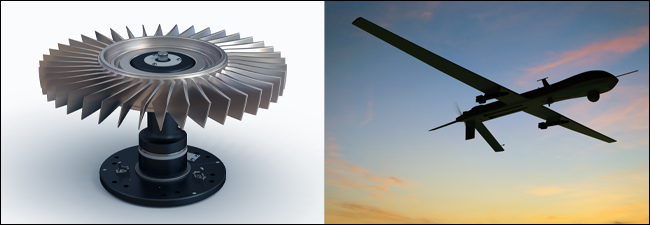

Compressors & Turbine Assemblies

Straighter assemblies enable reduced engine noise, reduced vibration, and increased fuel economy.

Significantly reduce engine build time with Taylor Hobson’s AEROStack Systems and avoid the need for reassembly with nearly 100% first-time build.

PGI Novus – Engine Blade Measurement

Engine blades are critical components used in several stages of jet engines. The thrust produced in such assemblies is directly related to the airflow around the blades, which helps reduce engine noise and vibration, in turn giving a direct improvement in fuel efficiency. More money is spent on Aero blades than any other part of a jet engine.

The Form Talysurf® PGI NOVUS offers many benefits over traditional measurement techniques which help to drive engine improvements. Not only offering next-level form accuracy over the entire complex blade shape including the leading and trialing edges but simultaneous roughness and waviness from a single measurement.

This complete measurement solution can be used in blade development and production control with the added benefits of dimensional control from an automated measurement.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.