We are facing what is being called “the new normal”, a situation to which all of us must adapt, and which confronts us with a paradigm shift at a time that had already been marked by profound transformation processes and in which the agility in change will be a key factor for future competitiveness and even more in the industrial sector.

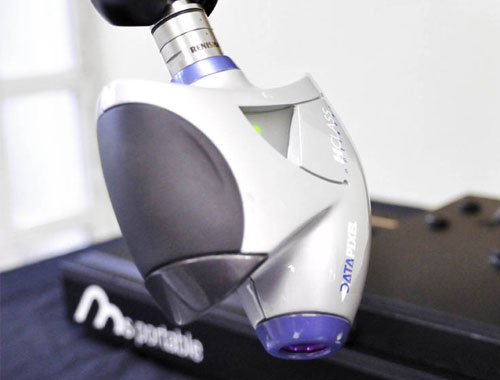

The crisis generated by COVID-19 is having a full impact on all worldwide industrial sectors since the lockout in productive activity in the industrial sector has been very intense and the forms of work are going to change substantially. It is, therefore, now more than ever necessary a “manufacturing without defects” and more automated and digitalized, which contributes to the optimization of production processes. And there, the role of quality control and global solution providers such as Innovalia Metrology. To do this, at Innovalia Metrology we continue to optimize our solutions to contribute to these new paradigms: increasing the obtainment of points from our optical sensors, automating measurement routines in M3 Software, and incorporating remote operation and maintenance solutions for CMMs. Not forgetting that close collaboration between parts manufacturers and suppliers of equipment and metrological solutions is now essential to face the challenges of the sector in the current and future situation.

Additionally, and as always, from Innovalia Metrology, we continue to work to be part of that digital, interconnected, and much more autonomous future, in which our products and services play a key role on the path towards digital excellence in the Industry.