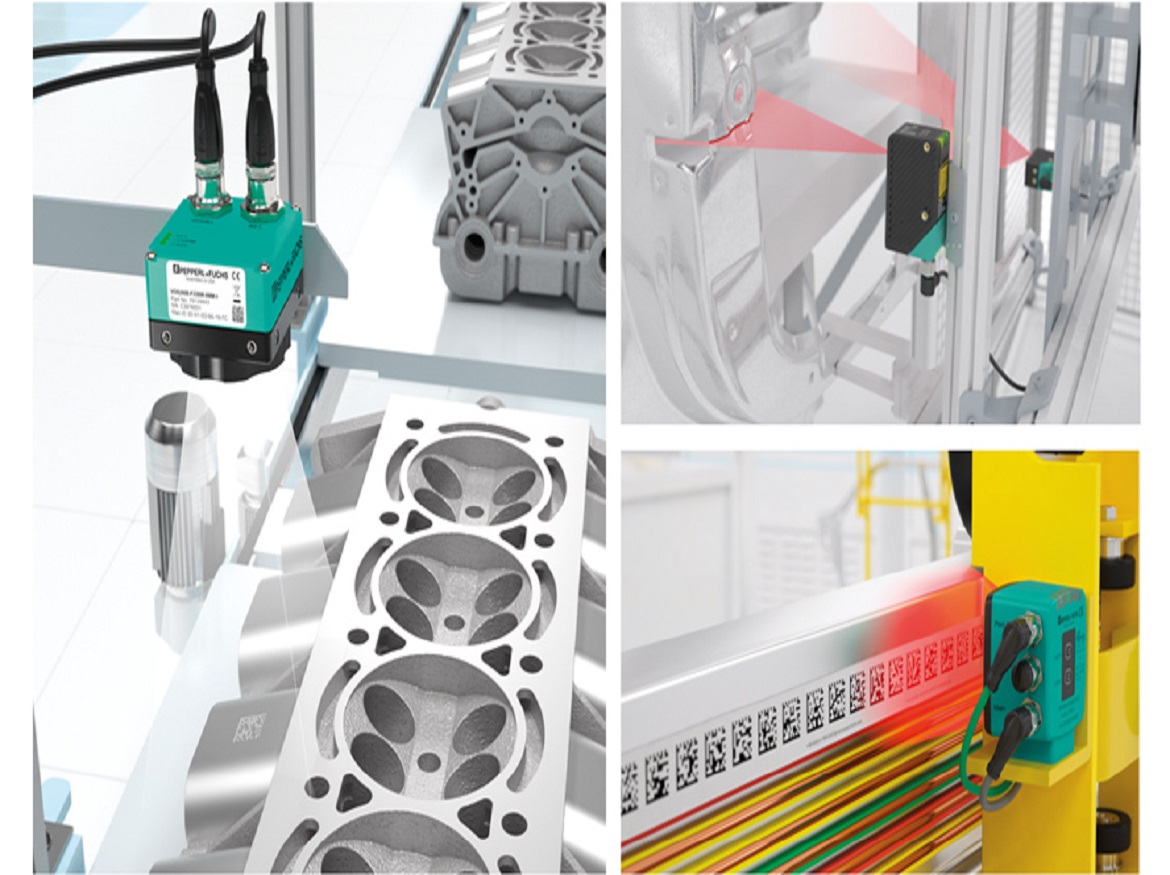

The automobile sector would be difficult to envision without industrial vision. The application fields of vision sensors are as varied as the industrial vision portfolio, whether for automatic component inspection, code reading on vehicle components, or the positioning of electric monorail systems. In this blog post, you can read more about three instances where vision sensors have been used in the automotive sector.

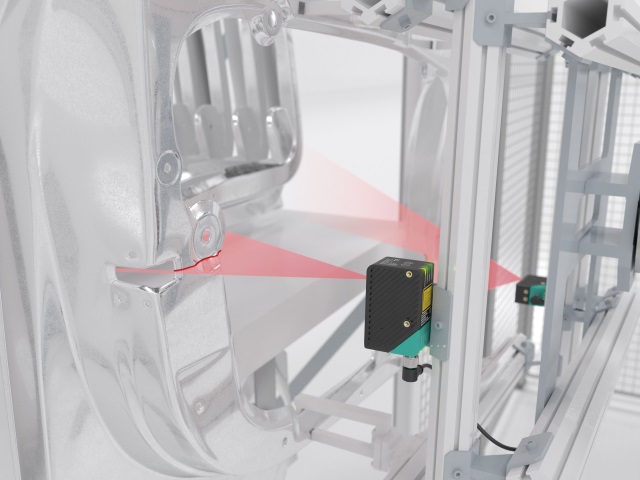

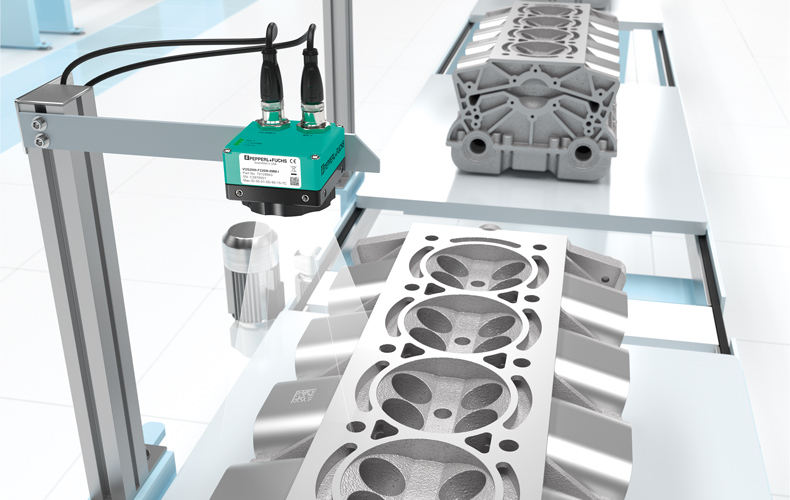

1. Automatic Component Inspection in Car Body Manufacturing with the SmartRunner Matcher

Robot welding cells are used in the automobile sector to join parts during the manufacture of car bodies. Prefabricated sheets are manually inserted into the robot arm for this purpose. A flawed sheet may become trapped in the gripper upon insertion. Certain contour features must be quickly detected in order to guarantee that the sheet is finished before the next phase. The robot gripper is equipped with a laser profile sensor from the SmartRunner Matcher series for this task.

The sensor recognizes the sheet’s contour and contrasts it with the height profile that was previously taught. By doing this, it directly transmits deviations, eliminating the need for the next work step. Regardless of object contrast or ambient light effect, the SmartRunner Matcher offers consistently reliable component detection. Additionally, a variety of connection choices for the laser profile sensor allow for intuitive parameterization and simple integration into various control systems.

2. Reliable Reading of 1-D, 2-D, and DPM Codes on Vehicle Components with the VOS-I

Data Matrix codes are used to identify components during processing steps and to guarantee consistently excellent quality in the automotive industry. The code is put on the component as a nameplate or as Direct Part Marking (DPM) by laser or needles, depending on the level of robustness necessary. The hurdles that code readers must overcome include reflective surfaces, imperfect or dirty codes, and the quick movement of components. Whether stationary on assembly lines or moving on robot arms, the VOS-I consistently reads all standard 1-D and 2-D codes at distances ranging from a few centimeters to two meters.

The complementary VOS-I vision sensor from Pepperl+Fuchs enables accurate reading of all popular 1-D and 2-D codes. The lighting of the sensor can be perfectly suited to the task. The VOS-I can enhance readability by using electronic filters to, for instance, expand the code or mask off-edge effects like scratches. In addition, I/O, Ethernet TCP/IP, PROFINET, EtherNet/IP, and RS-232 all offer the necessary interfaces for data communication. The script makes it simple to modify the output string for integration into the ERP system.

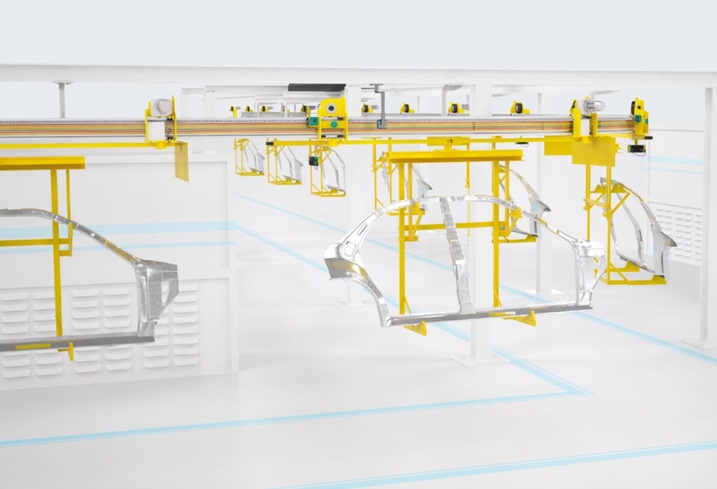

3. Reliable Positioning of Monorail Conveyors with the PXV Absolute Positioning System

Transporting drive trains, doors, engines, or entire car bodies throughout the assembly line is made possible by monorail conveyors. The carriers of the monorails have their own sensor, motor, and control systems. Regardless matter whether a route has inclines, curves, or switches, they dependably transfer the parts along each one while moving independently along the tracks. The carriers must be placed across the entire route with extreme precision in order to guarantee maximum availability and prevent downtimes brought on by collisions. The PXV absolute positioning system provides the best option with track lengths up to 100 km, position resolution of 0.2 mm, and transit speeds up to 8 m/s.

A Data Matrix coding tape is attached along the rail of the PXV absolute positioning system, and a read head is mounted directly on the carrier 100 mm away from the rail. The control system receives the 2-D camera’s output of the carrier’s current absolute position in relation to the Data Matrix coding tape. In contrast to previous technologies, the PXV does not require periodic calibration or maintenance, making commissioning quick and simple. With just one sensor, the safePXV model with PROFIsafe additionally provides particular protection for both man and machine in accordance with SIL 3/PL e.

Are You Still Looking for a Solution for Your Application?

A wide range of globally applicable vision sensors, application- or customer-specific devices, and turnkey solutions are available from Pepperl+Fuchs. In the realm of industrial vision, potent technologies can be employed to handle a wide range of tasks. Speak with specialists, and together we will identify the vision product or solution that best satisfies your unique needs.

Credits: Pepperl Fuchs

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.