Credits: Balluff

Introduction

The steel industry, a global economic powerhouse, plays a pivotal role in metal processing, automotive manufacturing, mechanical engineering, and construction. To thrive in this dynamic sector, the integration of cutting-edge technologies is imperative. In this blog post, they explore the impact of four key industrial automation solutions that are widely used in the steel industry: Magnetostrictive Linear Position Sensors, Proximity Sensors, IO-Link, and Protective Cables.

Magnetostrictive Linear Position Sensors: Precision in Harsh Environments

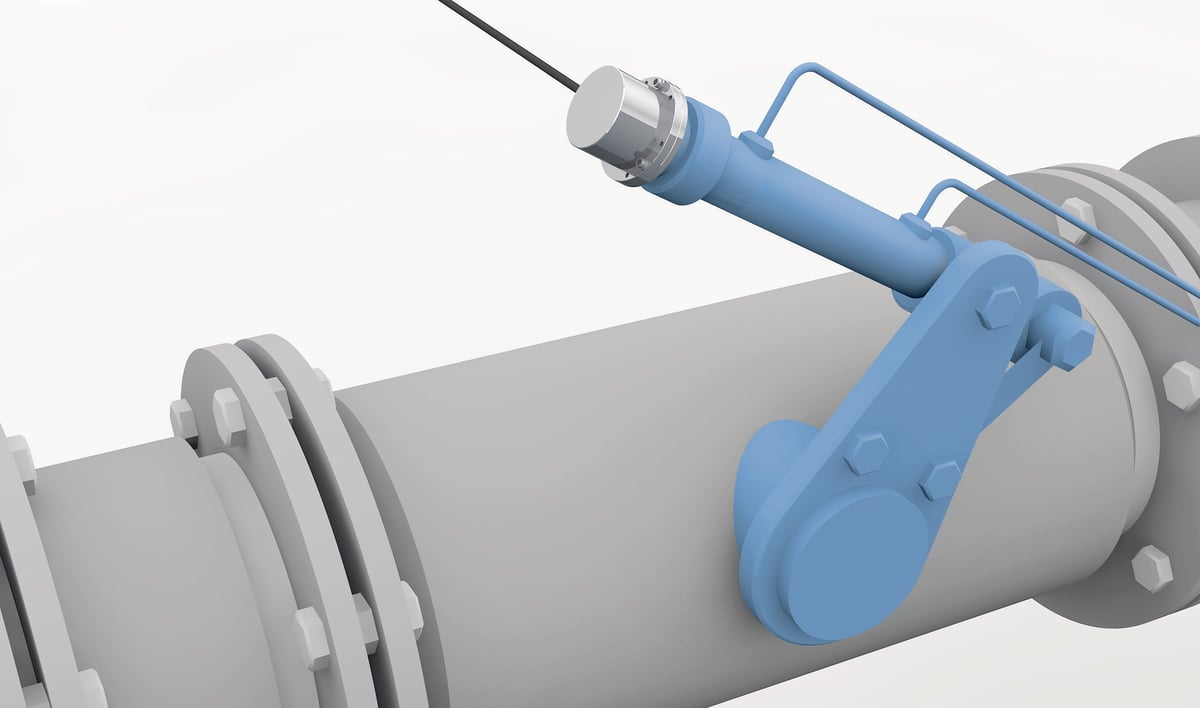

In the fast-paced realm of steel manufacturing, precise and contactless linear position measurement is of utmost importance. Magnetostrictive linear position sensors excel in this crucial task, providing precise monitoring of moving machinery components. These sensors seamlessly operate in challenging conditions, such as extreme temperatures and vibrations, making them indispensable for maintaining overall reliability and accuracy in control systems.

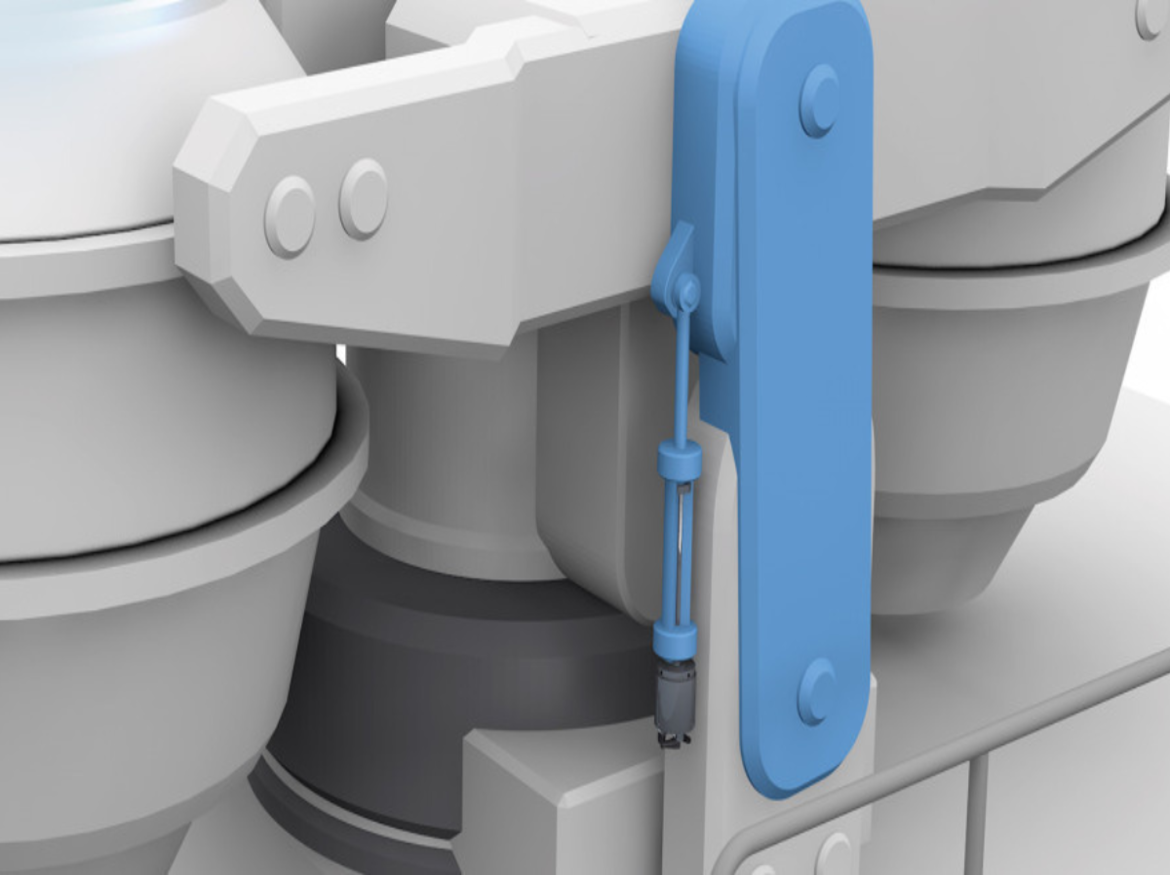

For critical processes like casting ladle movement, redundancy is key for safety. Multiple BTL magnetostrictive linear position sensors provide up to three independent measuring systems in one housing, ensuring the safe operation of continuous casting lines.

In the of pig iron production, where regulating air and gas supply are essential to optimize processes at the blast furnace. WIth magnetostrictive linear position sensors (BTL), one can regulate the intake and exhaust air safely and if equiped the models with bus interface, one can even measure the temperature of the system.

Proximity Sensors: Revolutionizing Equipment Monitoring

Precise equipment monitoring is the heartbeat of steel manufacturing. Proximity sensors have become indispensable in this regard because it operates without physical contact, these sensors detect the presence or absence of objects in real time, making them ideal for the challenging conditions of steel plants.

In steel production, hot zones can reach up to 160 °C, where high-temperature rated inductive sensors are needed to ensure optimal results for position sensing or end-of-travel detection on the pusher machine.

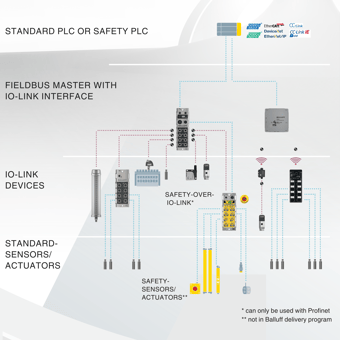

IO-Link: Bridging the Gap Between Sensors and Control Systems

The integration of modern sensor technologies with existing control systems is a challenge in the steel industry. IO-Link, a versatile communication standard, addresses this challenge by facilitating seamless communication between sensors and control systems. It enables real-time monitoring and control, increasing flexibility and efficiency in steel manufacturing processes.

IO-Link capable sensors, also known as smart sensors, can monitor various process parameters in the steel industry. This includes liquid levels, temperature, and even vibration data. These data play a vital role in operational processes and maintenance. They can be used to optimize operations and help a steel mill gain a competitive edge.

Balluff facilitates optimal networking of your network components, providing a crucial foundation for the industrial automation of your company.

Protective Cables: Ensuring Robust Connections in Harsh Environments

In a tough steel plant setting, having reliable sensor connections is crucial. Protective cables are engineered to withstand environmental challenges, including moisture, abrasion, and extreme temperatures. By investing in high-quality protective cables, steel manufacturers minimize the risk of disruptions caused by cable damage, contributing to improved system reliability and reduced maintenance costs.

Balluff offer connection technology, of high flexibility, reliability, and high-quality, suitable for various industries.

Summary: Transforming Steel Manufacturing Through Advanced Sensors

The combination of Magnetostrictive Linear Position Sensors, Proximity Sensors, IO-Link, and Protective Cables represents a powerful arsenal for the steel industry, enhancing efficiency and reliability. As these technologies evolve, steel manufacturers have the opportunity to embrace a new era of automation, where data-driven insights drive operational excellence for a more sustainable and competitive future.

Investing in these advanced sensor technologies not only addresses the current challenges faced by the steel industry but also positions manufacturers at the forefront of innovation. By leveraging the benefits of Proximity Sensors, IO-Link, Protective Cables, and Magnetostrictive Linear Position Sensors, steel plants can forge a path toward greater productivity, safety, and overall operational excellence.

At Balluff, they specialize in providing cutting-edge sensor solutions for the steel industry. With years of experience and a deep understanding of the unique challenges faced by steel manufacturers, they offer a wide range of sensors and automation solutions tailored to meet the demands of this dynamic industry.

Their team of experts is dedicated to helping steel plants optimize their processes, improve product quality, and enhance operational efficiency. Balluff has the expertise and solutions to drive success in the steel industry.